Manitowoc Published 07-19-16, Control # 249-01 1-71

2250 SERVICE/MAINTENANCE MANUAL INTRODUCTION

MAX-ER

®

2000 DESCRIPTION OF

OPERATION

MAX-ER Components

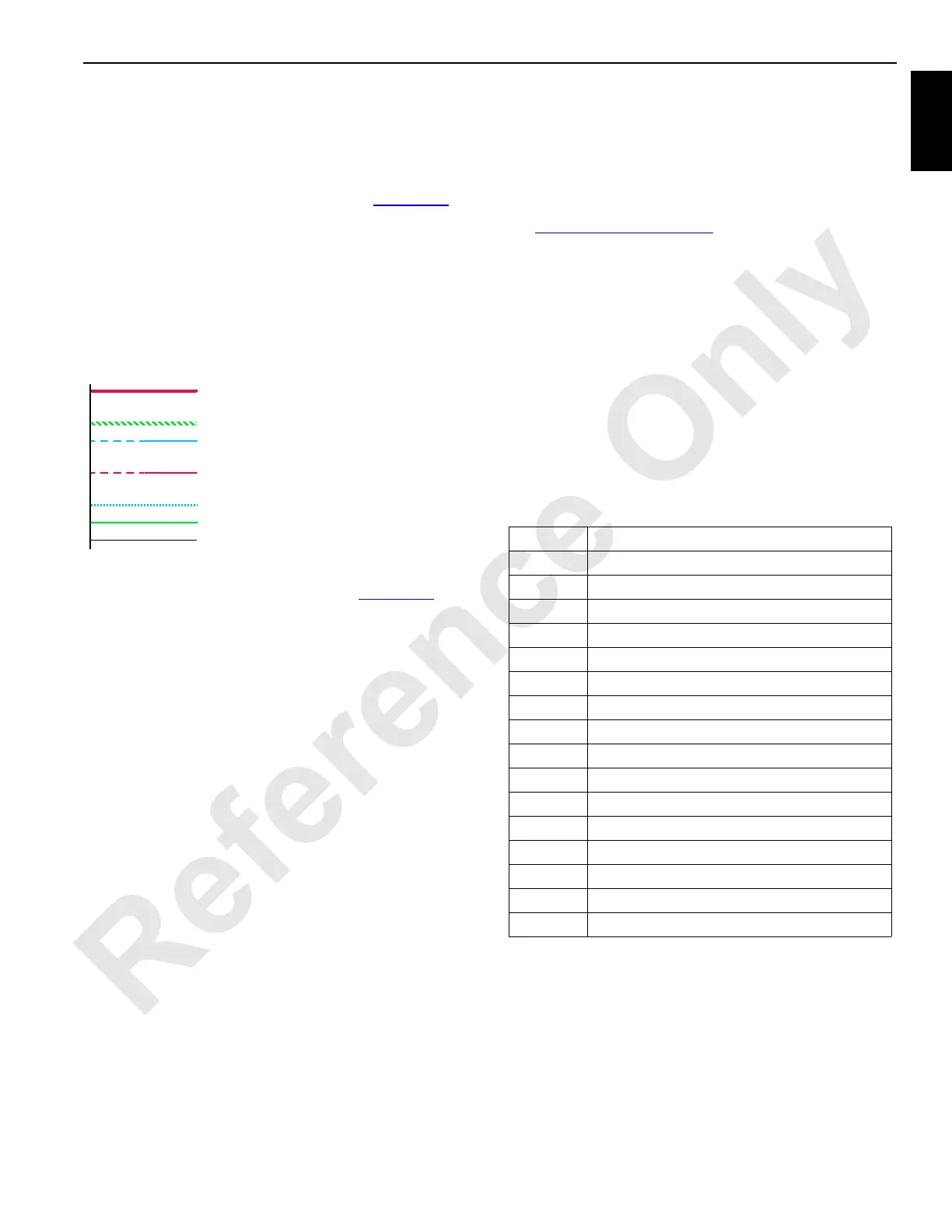

The line legend for all schematic is shown in Figure 1-44.

The MAX-ER 2000 combines a model 2250 crane with mast

and boom-butt-mounted load drum with a wheeled

counterweight assembly. The luffing jib attachment is also

usually part of most MAX-ER 2000s. See Section 3 of MAX-

ER 2000 Operator Manual for MAX-ER attachment

operation instructions or luffing jib attachment operation

instructions.

The MAX-ER 2000 wheeled counterweight assembly

consists of the following components (see Figure 1-45

):

• Wheeled Counterweight Assembly—This is suspended

from the mast by straps and hydraulic cylinders. An arm

connects the wheeled counterweight trailer to the rear of

the crane. The trailer wheels can be turned to permit the

crane to travel or swing when the trailer wheels are on

the ground.

• Counterweight Straps and Cylinders—These suspend

the wheeled counterweight assembly from the mast.

The strap cylinders automatically raise and lower the

counterweight in response to changes in the load

(weight of lifted load and boom angle).

• Load-Sensing Pin—Located in the gantry left side

backhitch, measures load tension created by the lifted

load. The load-sensing pin sends a proportional

0.8 to 8.0 V signal to the crane’s PC. The crane’s PC

enables the electrical and hydraulic systems to

automatically extend and retract the counterweight strap

cylinders to raise and lower the wheeled counterweight

assembly in response to changes in the backhitch

tension.

• Crane Programmable Controller (PC)—This controls the

crane and MAX-ER systems.

• MAX-ER Programmable Controller (PC)—This operates

the attachment’s electrical and hydraulic systems to

automatically raise and lower the wheeled

counterweight assembly in response to electronic

signals from the load-sensing pin, pressure senders,

and cylinder limit switch.

• Strap Cylinder Limit Switch—This limits how high the

wheeled counterweight assembly is raised.

MAX-ER Hydraulic Attachments

See Hydraulic and Air Systems Section 2 for the Hydraulic

Schematic.

Hydraulic attachments include the wheeled counterweight

trailer cylinders, mast stop cylinders, jib strut cylinders, and

load drum 9 in the boom butt. Hydraulic fluid used to operate

the attachments is from the auxiliary pump on the crane. In

MAX-ER mode, hydraulic fluid used to operate the drum 9

system is from the travel system pumps, boom hoist charge

pump, and fan auxiliary pump.

A hydraulic system that is open means fluid can flow in the

circuit. Each hydraulic solenoid valve is assigned an HS

number. The HS number identifies each hydraulic solenoid

valve.

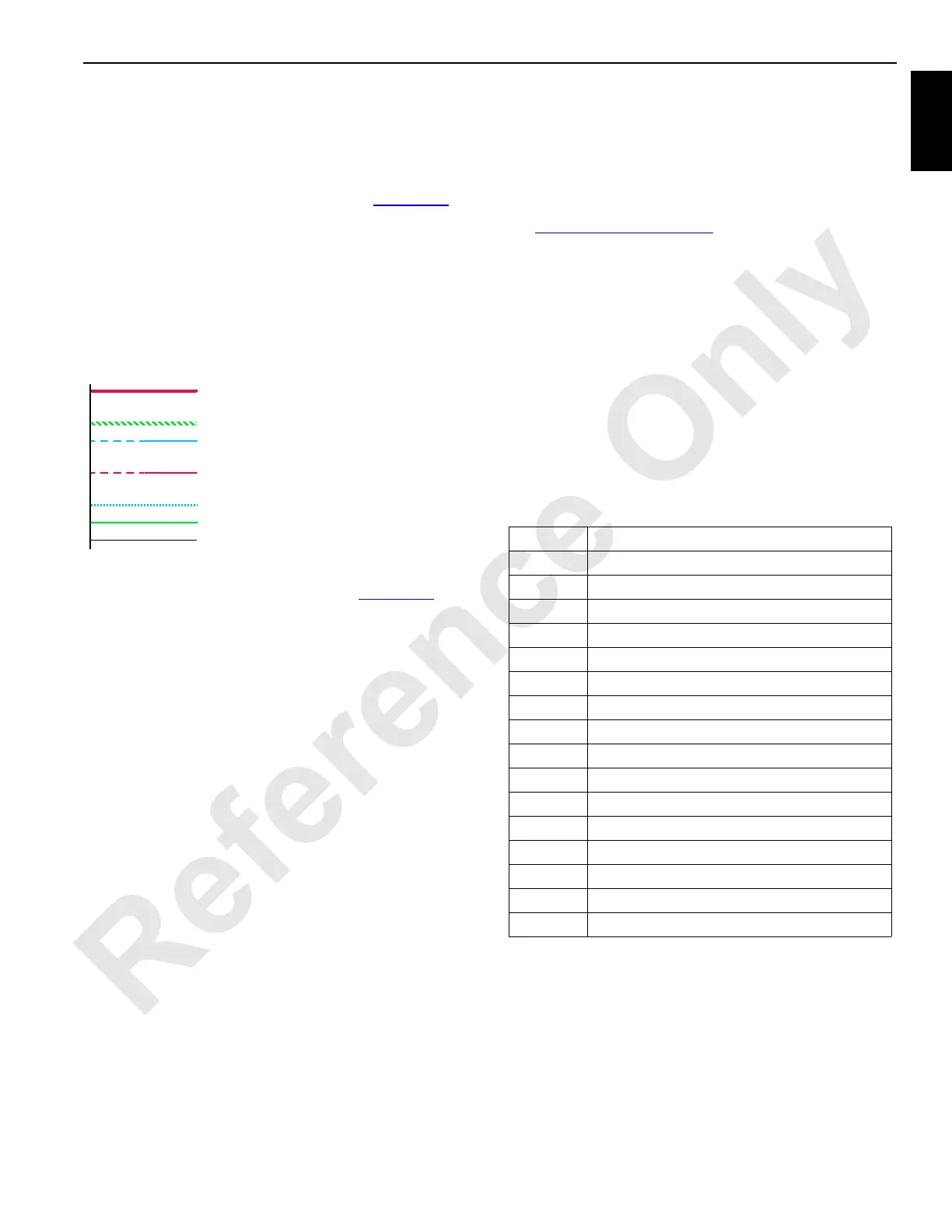

Table 1-4. Hydraulic Solenoid (HS) Valves

Auxiliary Pump

The main crane’s hydraulic tank supplies hydraulic fluid for

all attachments. The auxiliary pump draws fluid from the

crane’s hydraulic tank through a suction manifold. The

auxiliary pump supplies pressurized hydraulic fluid between

152 bar (2,200 psi) and 200 bar (2,900 psi) to the mast

accumulator system, MAX-ER accessory valve, and crane’s

accessory valve. The auxiliary pump’s pressure is monitored

and controlled by the mast accumulator pressure sender.

Line Legend for All Schematics

High-Pressure Hydraulic, Positive Electrical,

Manifold Air

Negative Electrical (ground)

Low-Pressure Hydraulic, Electrical Signal,

Exhaust Air

Control or Pilot Pressure Hydraulic,

Regulated Air

Case Return Pressure Hydraulic

Hydraulic Suction Manifold Pressure

Not Active Line or Circuit

FIGURE 1-44

HS-40 Strap Cylinders Lower (extend)

HS-41 Strap Cylinders Raise (retract)

HS-42 Swing/Crab—Steering Cylinder Extend

HS-43 Straight—Steering Cylinder Retract

HS-44 Left Jack Extend

HS-45 Left Jack Retract

HS-46 Right Jack Extend

HS-47 Right Jack Retract

HS-48 Center Jack Extend

HS-49 Center Jack Retract

HS-50 Tongue Cylinder Extend

HS-51 Tongue Cylinder Retract

HS-52 Steering Pins Engage

HS-53 Steering Pins Disengage

HS-54 Crawler Travel/Drum 9 Diverting

HS-55 Boom Hoist/Drum 9 Diverting

HS-56 Drum 9 Brake

Loading...

Loading...