HYDRAULIC AND AIR SYSTEMS 2250 SERVICE/MAINTENANCE MANUAL

2-12

Published 07-19-16, Control # 249-01

REPLACING A PRESSURE SENDER

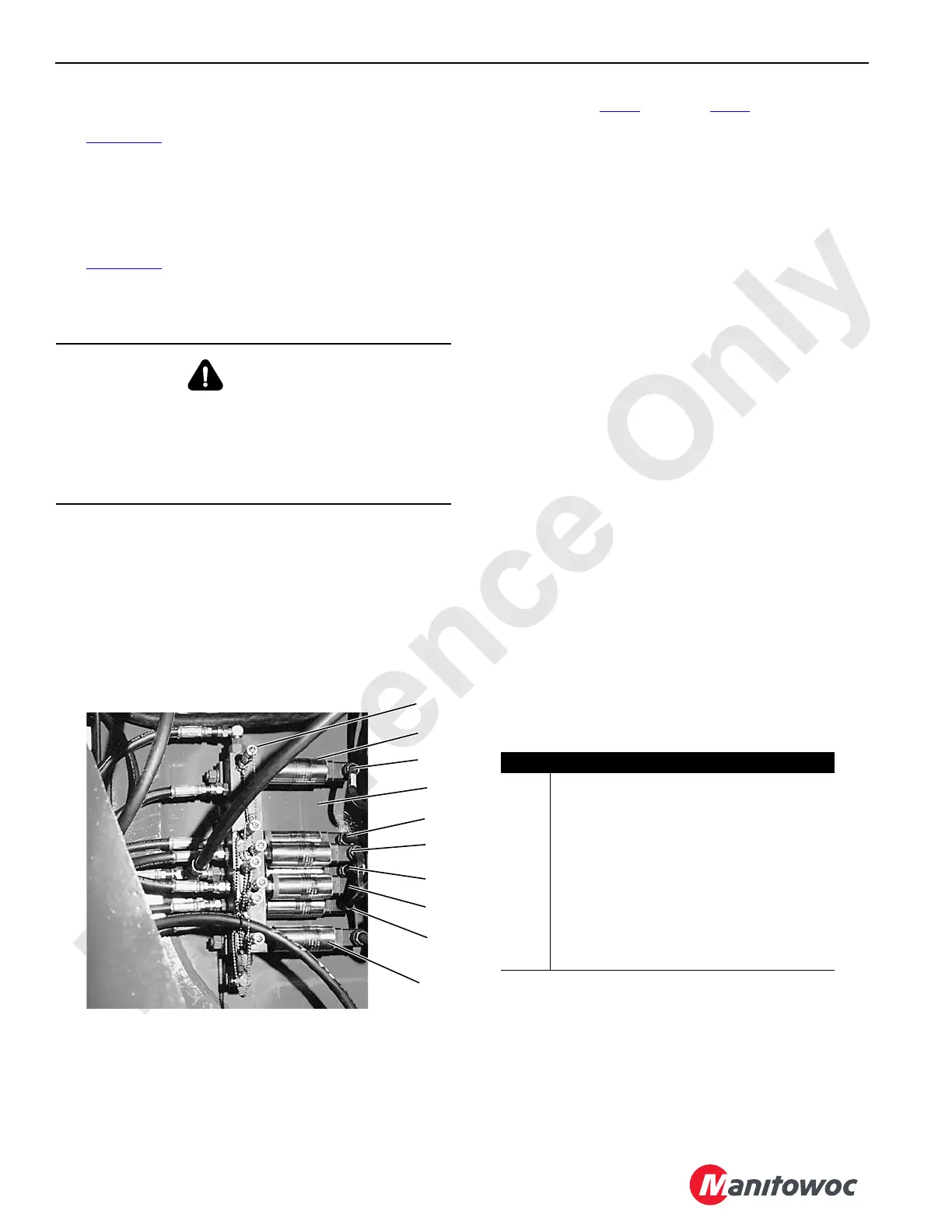

See Figure 2-16 for identification of the pressure senders.

General

These instructions must be followed to ensure safe removal

of faulty pressure senders and to ensure proper operation

after the installation of new pressure senders.

See Figure 2-16

for the following procedure.

NOTE: The replacement procedure is the same for all

pressure senders.

1. Lower all loads to the ground.

2. Move all control handles to OFF and park all crane

functions.

3. Stop the engine.

4. Place a suitable container under the pressure senders to

catch any oil leakage.

NOTE: Perform step 5

through step 9 only with faulty

pressure senders.

5. Disconnect the electric plug (2) from the pressure

sender.

6. Slowly loosen the pressure sender only enough to allow

any remaining pressure to exhaust.

7. Remove the pressure sender.

8. Install the new pressure sender and connect the electric

plug.

Pressure senders have pipe threads. Be sure to install

thread sealant.

9. Bleed the pressure sender as follows.

a. Connect a bleed line with a shut-off valve to the

gauge coupler (1) on the pressure sender manifold.

b. Open the valve in the bleed line and use a suitable

container to catch the oil flow.

c. With all control handles off, start the engine and

allow it to idle at 950 to 1,000 rpm.

d. Observe oil flowing from the bleed line.

e. Close the valve in the bleed line when clear oil flows

(no air bubbles in oil).

f. Stop the engine.

g. Remove the bleed line from the gauge coupler at

the pressure sender.

10. Calibrate the pressure sender.

CAUTION

High-Pressure Oil Hazard!

High-pressure oil can exhaust from the pressure sender

ports and cause minor to moderate injury.

Do not attempt to remove a pressure sender unless the

proper procedure is performed.

P930

2250 Left Inboard Side of Rotating Bed

(forward of pumps)

Item Description

1 Gauge Coupler (typical)

2 Electric Plug (typical)

3

Independent Luffing Hoist Pressure Sender

1

4 Right Travel System Pressure Sender

5 Left Travel System Pressure Sender

6 Load Drum Charge Pressure Sender

7 Load Drum System Pressure Sender

8 Boom Hoist System Pressure Sender

9 Swing Right System Pressure Sender

10 Swing Left System Pressure Sender

1

Optional

FIGURE 2-16

1

2

3

4

5

6

7

8

9

10

Loading...

Loading...