Manitowoc Published 07-19-16, Control # 249-01 2-39

2250 SERVICE/MAINTENANCE MANUAL HYDRAULIC AND AIR SYSTEMS

TYPE A AIR REGULATOR MAINTENANCE

Installation

Before installing the regulator, blow out the air line to remove

scale and other foreign matter. This unit has Dryseal pipe

threads. Use pipe compound or tape sparingly on male

threads only. Install the regulator in the air lines so that air will

flow in the direction of the arrow stamped on the body.

Adjustment

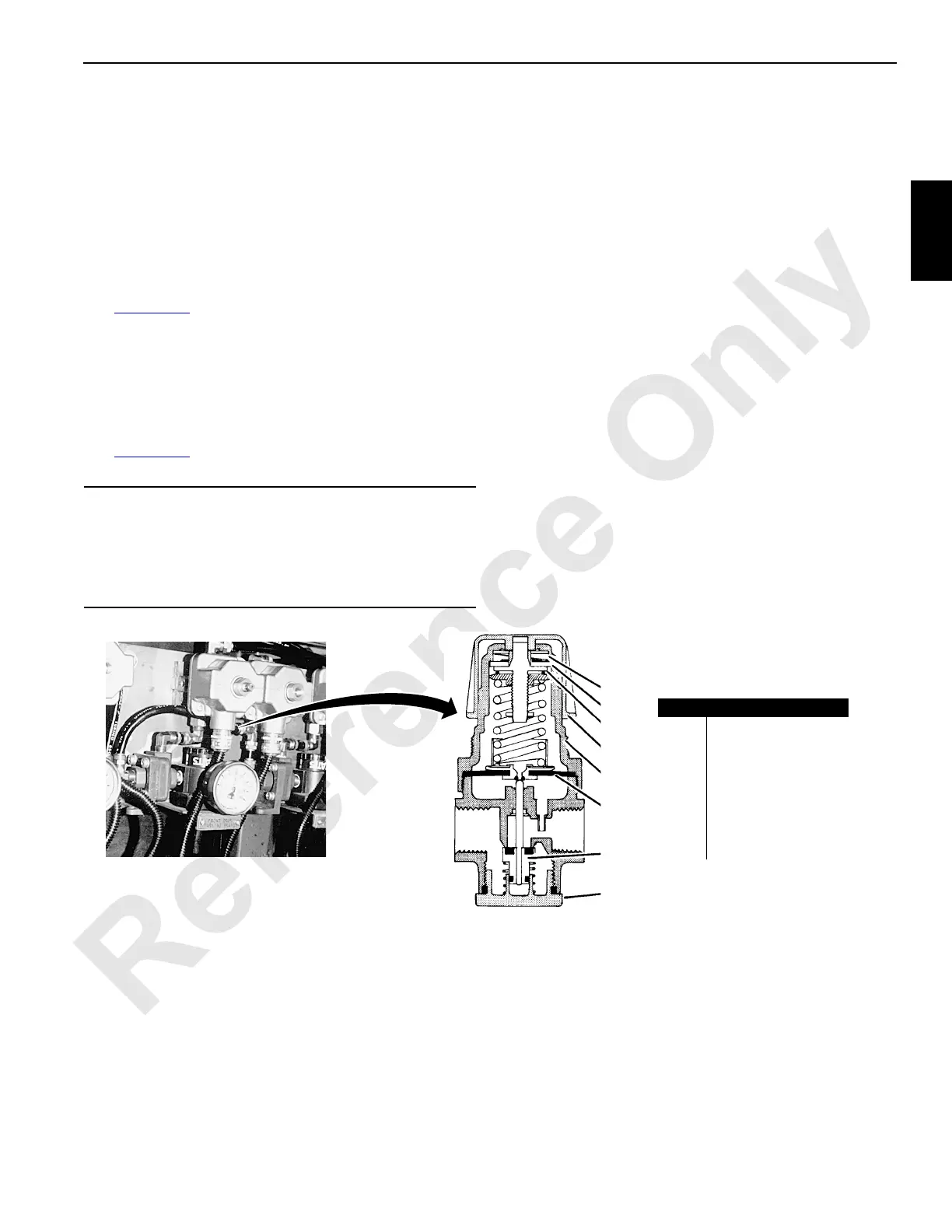

See Figure 2-43 for the following procedure.

To unlock the adjustment, push the knob (4) all the way

down. Turn the knob clockwise to increase regulated

pressure or counterclockwise to decrease pressure. To lock

the adjustment, pull the knob all the way up.

Maintenance

See Figure 2-43 for the following procedure.

NOTE: To clean, it is not necessary to remove the

regulator from the lines.

If the air supply is kept clean, the regulator should

provide long periods of uninterrupted service.

Erratic operation or loss of regulation is usually due

to dirt in the disc area.

To clean the regulator, perform the following procedure.

1. Shut off the air pressure and disassemble the regulator.

2. Clean all parts with denatured alcohol and blow out the

body with compressed air.

3. When reassembling, make sure the disc stem fits into

the center hole of the diaphragm assembly (6). If the

diaphragm assembly is replaced, make sure the disc

stem fits into its center hole.

4. Tighten the bonnet (8) slightly more than hand-tight

5,1 Nm (45 in-lb).

CAUTION

Equipment Damage!

Certain chemicals can degrade non-metal components.

Never use carbon tetrachloride, trichloroethylene, thinner,

acetone, or similar solvents when cleaning any part.

S118

P310

FIGURE 2-43

Item Description

1 Lock Assembly

2 Adjustment Screw

3 Adjustment Knob

4Knob

5 Spring Cage

6 Diaphragm Assembly

7 Disc Assembly

8 Bonnet

1

2

3

4

5

6

7

8

Loading...

Loading...