Manitowoc Published 07-19-16, Control # 249-01 2-9

2250 SERVICE/MAINTENANCE MANUAL HYDRAULIC AND AIR SYSTEMS

Table 2-8. Split Flange Leakage

SAE Flare Connection

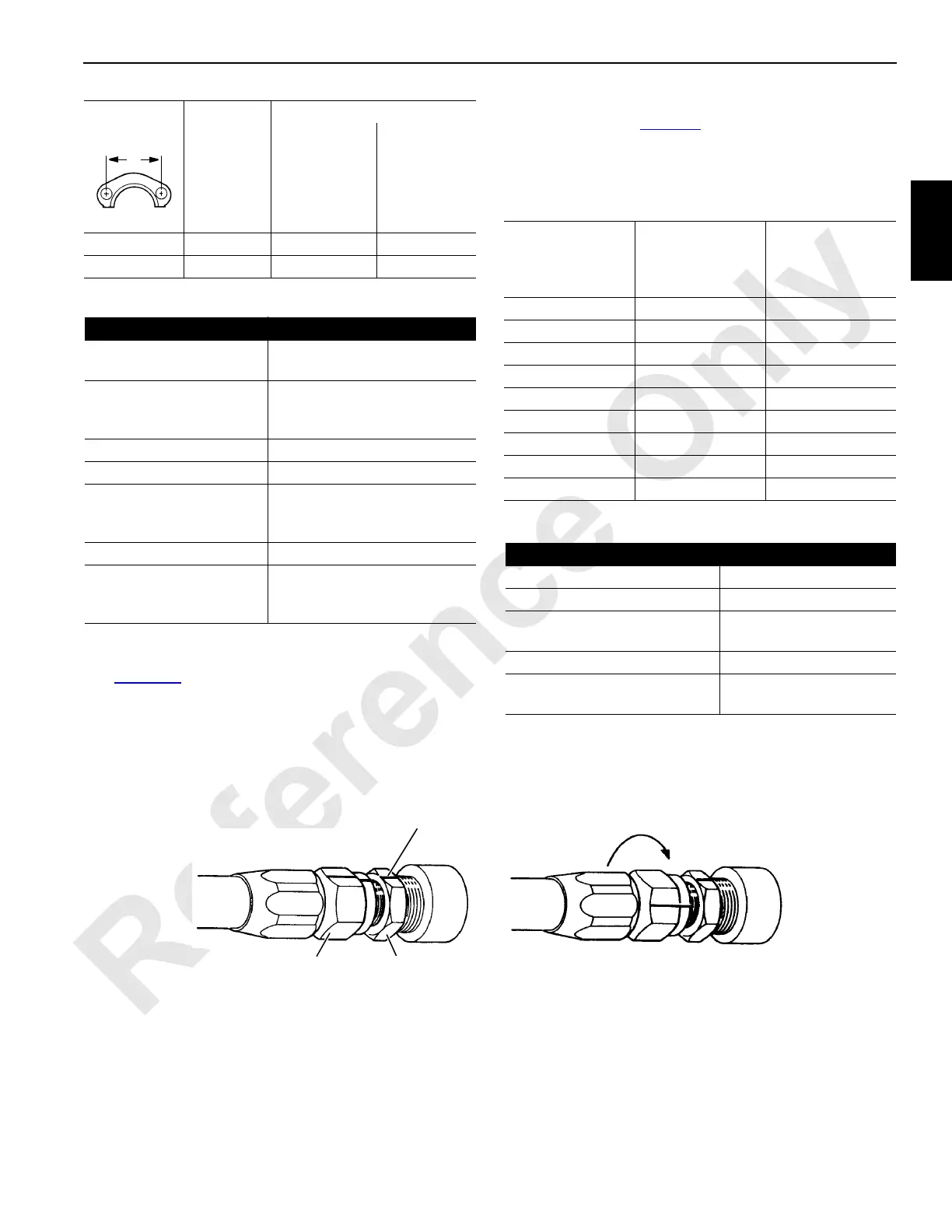

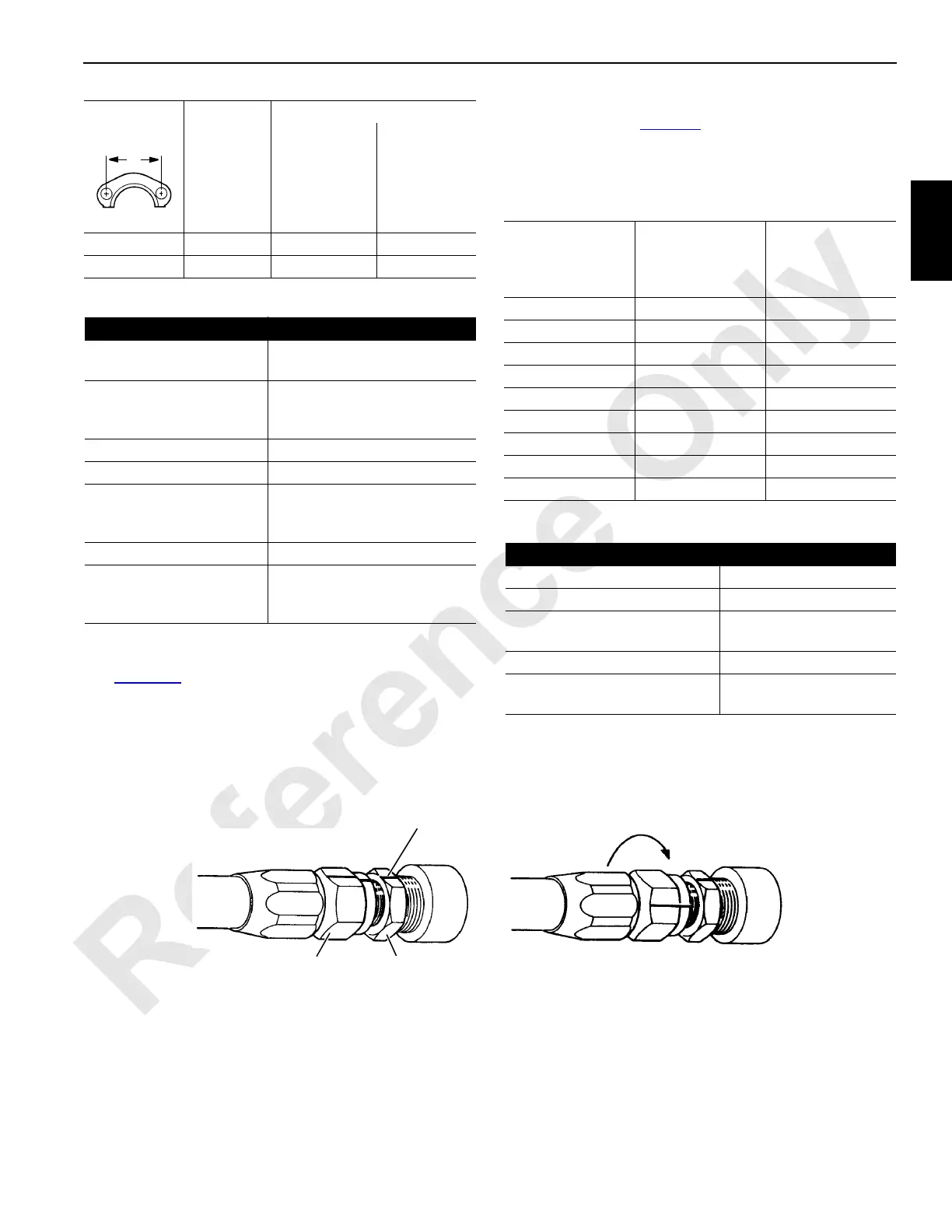

See Figure 2-9 for the following procedure.

1. Tighten the nut finger tight until the sealing surfaces

touch.

2. Using a felt pen or marker, mark a line on the adapter

and extend it onto the connector nut (View A).

3. Using wrenches, tighten the connector nut the number

of flats shown in Table 2-9

.

Misalignment of the marks will show how much the nut

has been tightened.

Table 2-9. SAE 37° Flare Tightening

Table 2-10. SAE 37° Flare Leakage

3-1/8 -24 158 to 181 1400 to 1600

3-13/16 -32 271 to 294 2400 to 2600

Cause Cure

Flanges not tight Tighten bolts evenly to proper

torque

Flanges tightened

unevenly causing

extrusion of O-ring

Replace O-rings and tighten

bolts evenly to proper torque

O-ring cut Replace

O-ring wrong size Replace with proper size

Sealing surfaces are not

smooth. They are

scratched or gouged.

Repair if possible or replace

parts

Sealing surfaces dirty Clean

Flanges keep getting

loose in service

Use SAE grade 5 bolts or

better and retighten bolts after

system is hot

Dimension A

inch

Flange

Size

Torque

Nm in-lb

Connector Nut

Size

(inch across

flats)

Fitting Size

Adapter Flats

to Rotate

9/16 -04 2-1/2

5/8 -05 2-1/2

11/16 -06 2

7/8 -08 2

1 -10 1-1/2 to 2

1-1/4 -12 1

1-1/2 -16 3/4 to 1

2 -20 3/4 to 1

2-1/4 -24 1/2 to 3/4

Cause Cure

Joint loose Tighten properly

Sealing surfaces dirty Clean

Sealing surfaces are scratched

or gouged

Replace faulty parts

Sealing surfaces cracked Replace faulty parts

SAE 45° parts used with SAE

37° parts

Use only SAE 37°parts

S108

FIGURE 2-9

Connector

Nut

Adapter

Line

Turn connector nut required number of flats

View A View B

Loading...

Loading...