BOOM 2250 SERVICE/MAINTENANCE MANUAL

4-8

Published 07-19-16, Control # 249-01

Raising the Boom Stop to the Working

Position

See Figure 4-4 for the following procedure.

1. Connect the socket to the plug in the air supply line near

the right side boom hinge pin as shown in View C.

2. Start the engine. The strut cylinders will extend to raise

the boom stop tubes as air pressure is supplied.

3. Remove the quick-release pin from both strut supports

and rotate the supports to the working position as

shown.

4. Reinstall the quick-release pins to lock the struts in

position.

Adjustments

See Figure 4-4 for the following procedures.

The physical boom stop was adjusted at the factory and

does not require periodic adjustment. The following items

must be verified and adjusted at assembly, however, if the

boom stop is disassembled for repair or parts replacement.

Boom Stop Rod Ends

Verify that each boom stop rod end is threaded all the way

onto the cylinder rod so the rod end is snug against the

shoulder on the cylinder rod as shown in View B. Also, make

sure to install the rod end guides. The guides keep the boom

stop rod ends in proper alignment.

Boom Stop Engagement

Watch the boom stop rod ends while slowly raising the boom

butt. Both of the rod ends must engage the boom stop pins in

the rotating bed at the same time and at the approximate

point shown in View B. Adjust the boom stop rod end for

each strut cylinder to provide the proper engagement.

Boom Stop Compression

Watch the boom stop rod ends while slowly raising the boom

butt. With the boom butt at 90

°, both boom stop rod ends

should be bottomed out against the cylinders to within

3,2 mm (1/8 in) of each other as shown in View D.

Install the U-shaped spacers between the cylinder flanges

and the boom stop tubes as shown in View D to limit the

maximum angle to 90

° and to bottom out the rod ends to

within 3,2 mm (1/8 in) of each other.

ANGLE INDICATOR SENDING UNIT

ASSEMBLY

General

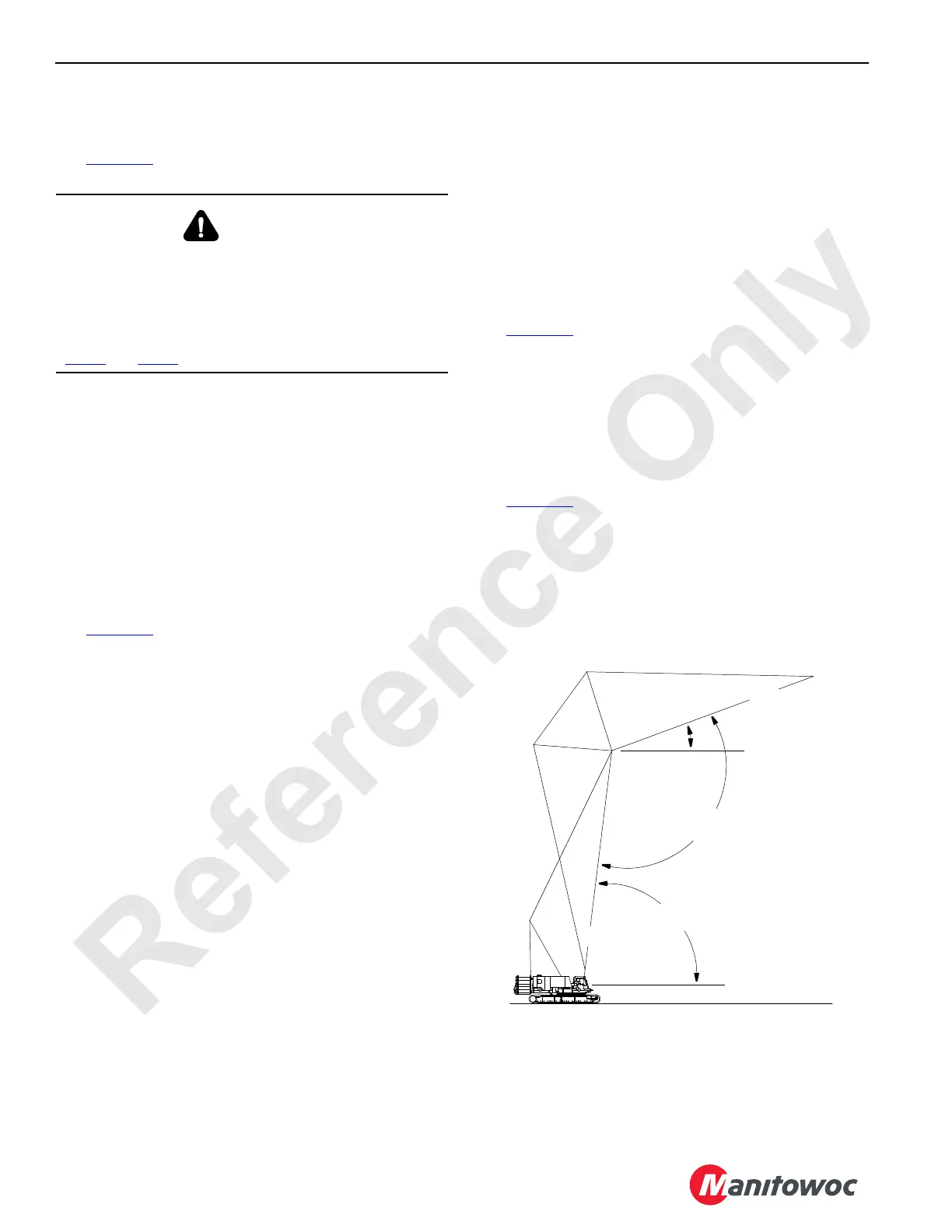

See Figure 4-6 for the following.

An angle indicator sending unit (2) is mounted on the boom

butt (6) and, if equipped, on the luffing jib butt (1).

Each sending unit houses an angle sensor that sends an

electrical signal to the crane’s programmable controller. The

programmable controller converts the signal into an angle

which can be monitored on the digital display in the

operator’s cab.

See Figure 4-5

for the following.

The following three angles can be monitored:

• Boom angle

• Luffing jib angle

• Boom-to-luffing jib angle

WARNING

Crushing Injury Hazard!

The strut cylinders will extend as air pressure is supplied,

creating a hazardous situation in which death or serious

injury may occur.

Stand clear of the boom stop tubes while performing

step 1

and step 2.

Boom and Jib Angle Identification

A528

C

L

C

L

Boom

Boom-to-Luffing

Jib Angle

Boom Angle

Horizontal

Horizontal

Luffing Jib

Luffing Jib

Angle

FIGURE 4-5

Loading...

Loading...