UNDERCARRIAGE 2250 SERVICE/MAINTENANCE MANUAL

8-2

Published 07-19-16, Control # 249-01

When new bolts are installed, tighten the bolts in two steps,

as follows.

1. Tighten all bolts to 814 Nm (600 lb-ft).

2. Tighten all bolts to 2 848 Nm (2,100 lb-ft).

Torque Intervals

Tighten all bolts to the specified torque value at the following

intervals:

• After the first 50 hours of operation

• Yearly or every 2,000 hours of operation (whichever

comes first

Replacing the Turntable Bearing Bolts

If, at the yearly inspection interval, one or more bolts are

found to be tightened to less than 2 278 Nm (1,680 lb-ft),

replace the loose bolt(s). Also replace the bolts and washers

on each side of each loose bolt.

If, at the yearly inspection interval, twelve or more bolts for

either ring are found to be tightened to less than 2 278 Nm

(1,680 lb-ft), replace all of the bolts and washers for the

corresponding ring.

Replace all of the bolts and washers each time a new

turntable bearing is installed.

CRAWLER ADJUSTMENT

Maintenance

Crawler wear cannot be eliminated, but the rate of wear can

be reduced through regular preventive maintenance, as

follows:

• Lubricate the crawlers as instructed in Lubrication

Section 9.

• Keep the crawlers clean and avoid dirt buildup when

cutting.

• Keep all mounting bolts tight (see the parts manual for

applicable torque values).

• Keep the treads properly adjusted.

• Inspect the crawler gear cases, crawler frames, rollers,

treads, and drive shafts on a regular basis.

Look for oil leaks, excessive wear, cracks, and other

damage. Broken or cracked parts can indicate that the

treads are adjusted too tight.

Repair or replace any damaged parts immediately to

prevent further damage.

Adjusting the Tread Slack

Crawler Adjustment Guideline

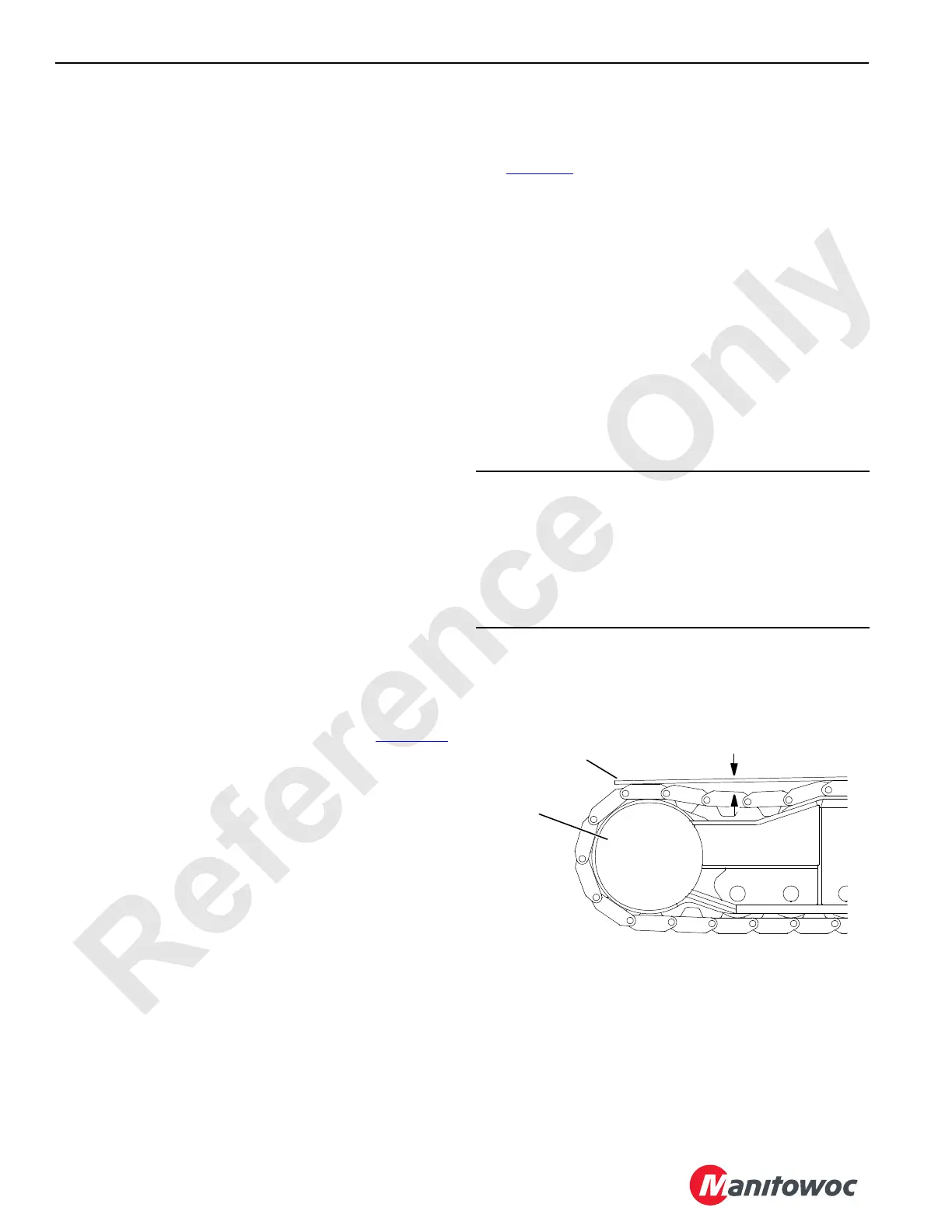

See Figure 8-2 for the following procedure.

Check for tread slack at the tumbler end of each crawler.

Maintain equal tread slack at both crawlers.

1. Travel forward on a firm, level surface so that all of the

tread slack is in the top of the treads at the tumbler end

of the crawlers.

2. Place a straightedge on the treads as shown. The gap

between the straightedge and the top of the tread at the

lowest point should be as follows:

- Tight limit—25 mm (1 in)

- Loose limit—63 mm (2.5 in)

3. Adjust the tread slack if the gap is less than the tight limit

or greater than the loose limit.

4. Adjust the treads tighter when operating on firm ground

or looser when operating on soft ground (mud or sand).

CAUTION

Equipment Damage!

More torque is required to drive tight treads, which results

in faster wear, possible pin breakage, and more fuel

consumption. Dirt buildup will tighten the treads even

more, increasing the possibility of damage.

Adjust the treads exactly as specified.

FIGURE 8-2

Straightedge

Crawler

Tumbler

Gap

25 mm (1 in) Tight Limit

63 mm (.25 in) Loose Limit

A1052

Loading...

Loading...