Manitowoc Published 07-19-16, Control # 249-01 3-1

2250 SERVICE/MAINTENANCE MANUAL ELECTRICAL SYSTEM

SECTION 3

ELECTRICAL SYSTEM

ELECTRICAL DRAWINGS AND

SCHEMATICS

Applicable electrical system drawings and schematics are

located at the end of this section.

INSPECTING OR REPLACING ELECTRICAL

COMPONENTS

Electrical Harnesses and Cables—Monthly

or 200 Hour Service Life Inspection

Visually inspect all of the electrical harnesses and cables for

the following conditions:

• Damaged, cut, or deteriorated harness loom

covering

• Damaged, cut, or abraded individual wires or cable

insulation

• Exposed bare copper conductors

• Kinked, crushed, or flattened harnesses or cables

• Blistered, soft, or degraded wires and cables

• Cracked, damaged, or badly corroded battery

terminal connections

• Damaged terminals or excessive corrosion at the

machine ground connections

• Other signs of significant deterioration

If any of these conditions exist, evaluate the harness for

repair or replacement.

Electrical Junction Boxes—Monthly or

200 Hour Service Life Inspection

Visually inspect all of the electrical junction boxes for the

following conditions:

• Damaged or loose connectors

• Damaged or missing electrical clamps or tie straps

• Excessive corrosion or dirt on the junction boxes

• Loose junction box mounting hardware

If any of these conditions exist, address them appropriately.

Electrical Harnesses and Cables—Service

Life

Electrical harnesses and cables potentially have different

service lives based on the climate zones they are operating

in. Take into consideration if the crane is moved and

operated in different climate zones. The service life will be a

combination of the recommended intervals. See Table 3-1

for the following items:

• Harness and battery cables operating in Zone C are

recommended to be replaced after 10,000 hours of

service life.

• Harness and cables operating in Zone A and Zone

B with high ambient temperatures and high-duty

circuits could see electrical service life reduced by

25% to 40%. It is recommended to replace these

assemblies after 8,000 hours of service life.

• Harness and cable assemblies operating in climate

Zone D and Zone E should expect a degrade of

mechanical properties. Long-term exposure to

these cold temperatures will negatively impact the

service life. It is recommended for these electrical

harnesses and cables to be inspected monthly or

every 200 hours, since service life may be more

than 10,000 hours.

• Harness and cable assemblies operating in salt

water climates could see a significant reduction in

service life. Therefore, it is recommended for these

electrical harnesses and cables to be inspected

monthly or every 200 hours, since service life may

be more than 8,000 hours.

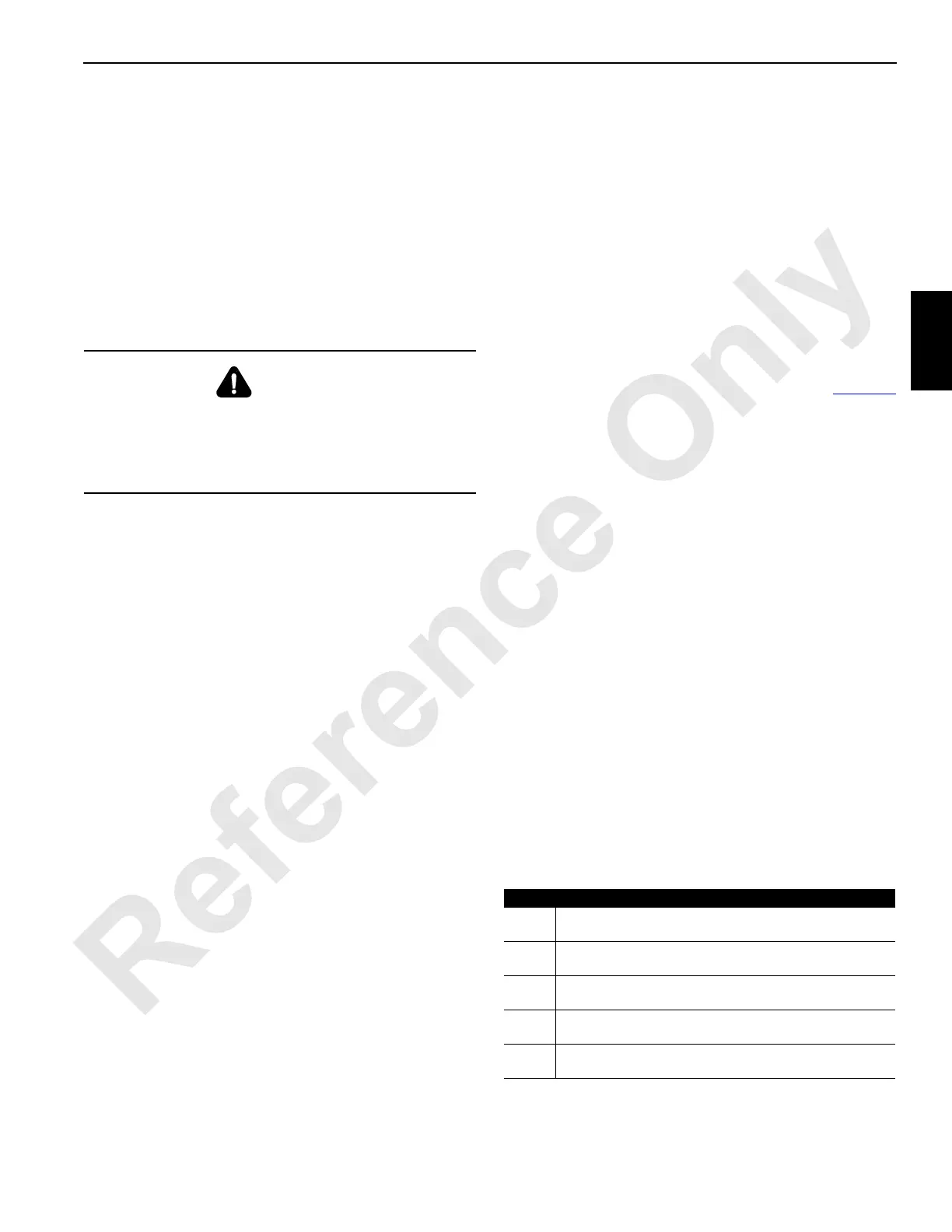

Table 3-1. Climate Zone Classification

DANGER

Electrical Shock Hazard!

Prevent personal injury from electrical shock.

Ensure that the battery cables are disconnected from the

batteries before loosening any electrical connections.

Item Description

A Tropical Moist: All months average above 18°C.

Latitude: 15° to 25° N & S

B Dry or Arid: Deficient precipitation most of the year.

Latitude: 20° to 35° N & S

C Moist Mid-Latitude: Temperate with mild winters.

Latitude: 30° to 50° N & S

D Moist Mid-Latitude: Cold winters.

Latitude 50° to 70° N & S

E Polar: Extremely cold winters and summers.

Latitude: 60° to 75° N & S

Loading...

Loading...