Manitowoc Published 07-19-16, Control # 249-01 1-97

2250 SERVICE/MAINTENANCE MANUAL INTRODUCTION

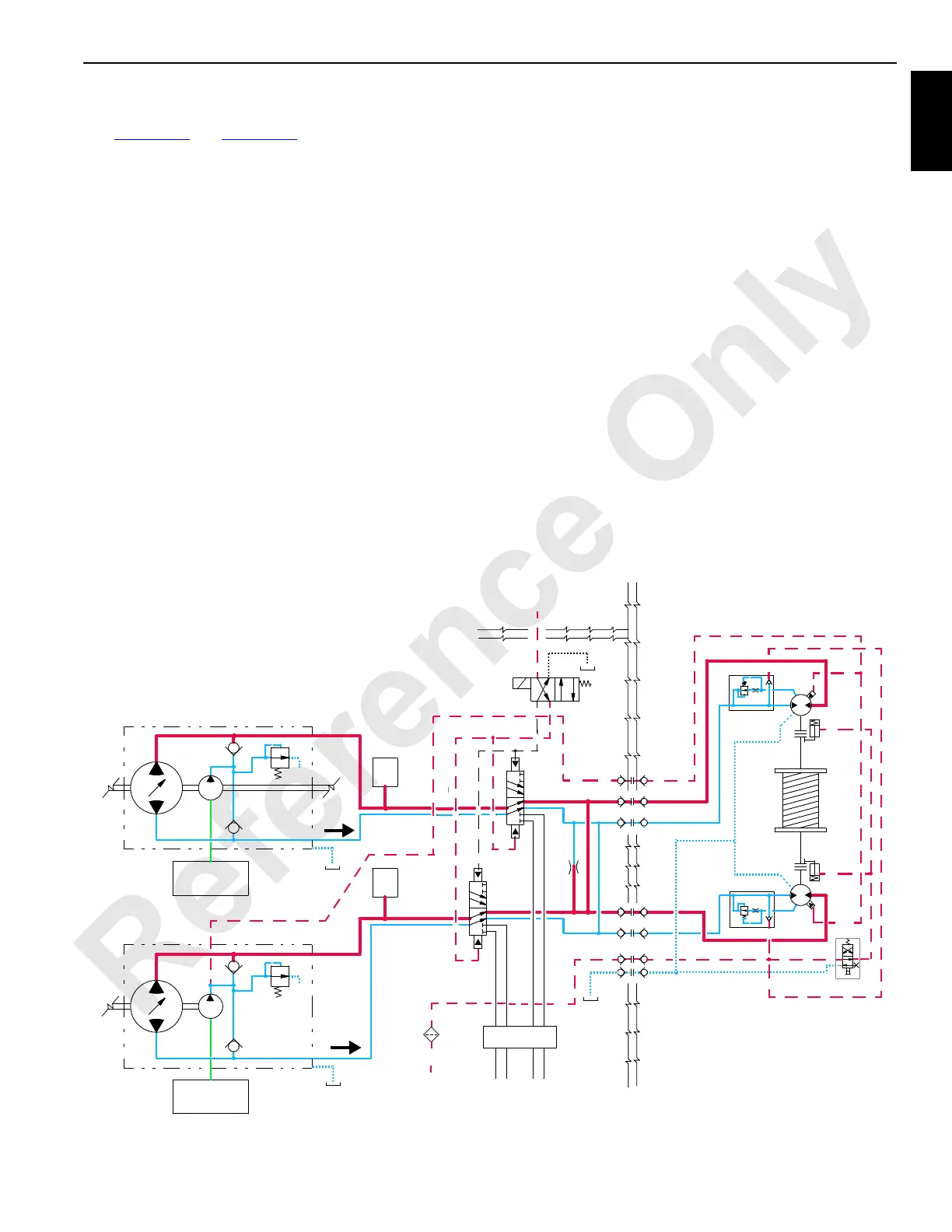

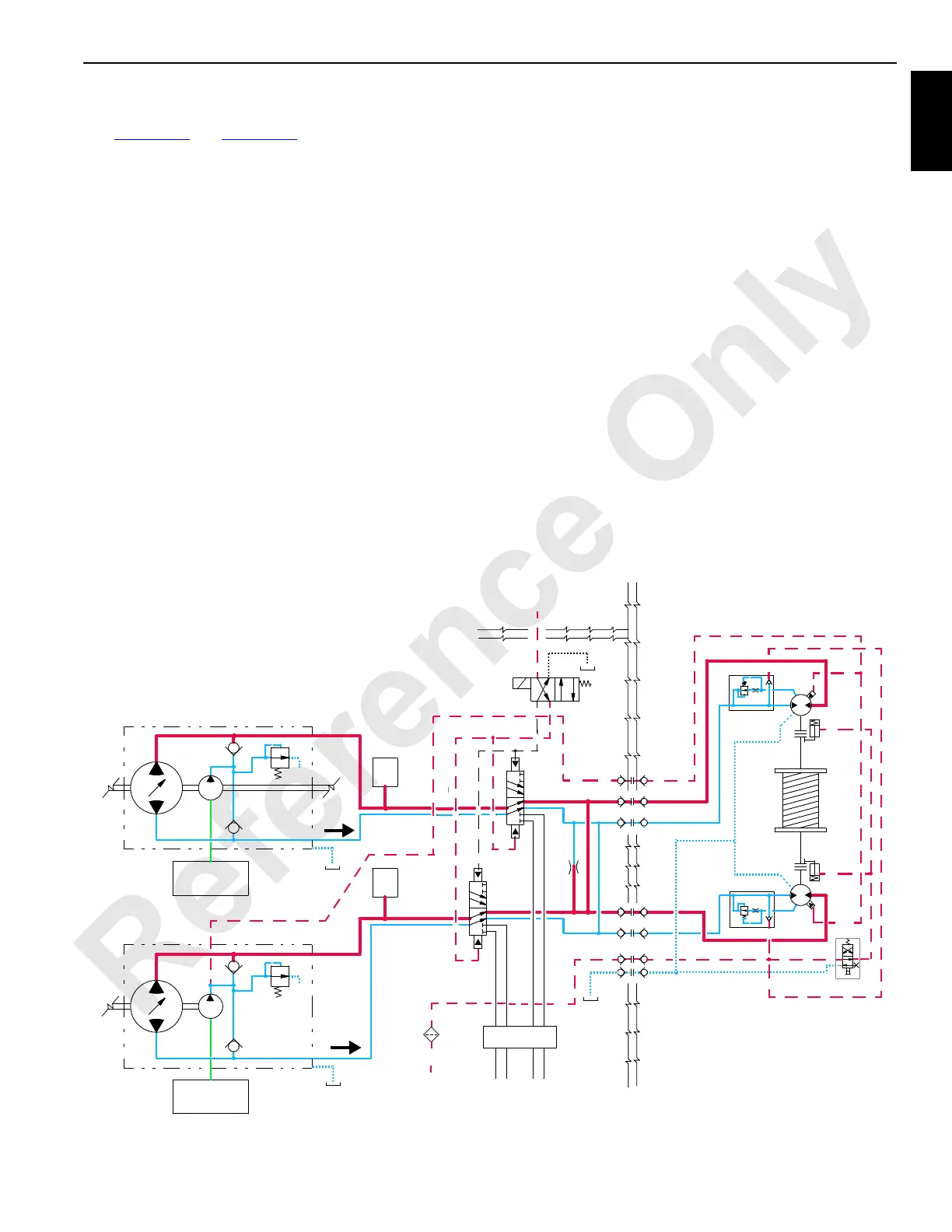

Drum 9 Lowering (MAX-ER Mode)

See Figure 1-63 and Figure 1-64 for the following.

When the left control handle (drum 9) is moved forward to

(lower), the handle neutral switch closes, sending an output

voltage of 5 V or less to the crane’s PC. The PC sends an

output signal to shift the diversion solenoid valve HS-54 to

allow the fluid to flow from the crawler’s travel pumps through

the diverting valve to the drum 9 motors.

The crane’s PC sends a negative output signal to stroke the

crawler’s travel pumps momentarily in the RAISE direction to

satisfy pressure memory. The PC compares drum-holding

pressure to the value stored in pressure memory. When

system pressure is high enough, the PC sends a positive

output signal to enable the brake solenoid HS-56. The brake

solenoid shifts to block the tank port and opens the port to

system charge pressure to release the brake.

The PC sends a positive output signal to stroke each crawler

travel pump’s EDC in the lower direction and a positive

output signal to each motor’s PCP. The crane’s PC checks

that the block-up limit switches are closed with no other

system operating limits present.

The crane’s PC sends a negative output voltage to each

pump’s EDC that tilts the pump’s swashplate in the LOWER

direction. Hydraulic fluid at system pressure up to 407 bar

(5,900 psi) maximum flows from pump ports B to port B of

the motors. Fluid from motor ports A returns to pump ports A.

The load weight attempts to drive the motors faster than

return fluid is available to the pumps. The system charge

pump maintains fluid supply at a positive pressure to the

motors. The position of each pump’s swashplate restricts the

returning fluid flow. Pressure builds on the return fluid side of

the closed-loop system, acting as a brake against the motors

to control the lowering speed.

The crane’s PC controls the lowering speed by varying the

voltage sent to the EDCs in relation to the left control

handle’s movement to program requirements. Each pump’s

swashplate angle is increased as the handle is moved

forward. As more fluid is returned to the pumps, more fluid is

pumped to the motors, and the drum lowers the load faster.

When the left control handle is moved to the neutral position,

the crane’s PC sends an output signal to the travel pump’s

EDCs to decrease the swashplate angle, reducing oil flow

output. The crane’s PC stores the load-holding pressure in

pressure memory. After the control handle’s neutral switch

opens, the PC sends an output signal to disable the brake

solenoid HS-56 to apply the brake before the crawler travel

pumps de-stroke.

24 bar

(350 psi)

Right Travel Pump

Left Travel Pump

To Travel

Motors

T

T

HS54

RM-20

A

B

A

B

HS56

Crane

Drum 9

24 bar

(350 psi)

Swivel

Suction

Manifold

Suction

Manifold

Hoist Charge Pump

A

B

B

A

Boom

UP

DOWN

DOWN

UP

From Boom

Flow

Flow

Brake Line

from

Fan Circuit

Servo Line

FIGURE 1-64

Loading...

Loading...