Manitowoc Published 07-19-16, Control # 249-01 2-7

2250 SERVICE/MAINTENANCE MANUAL HYDRAULIC AND AIR SYSTEMS

TIGHTENING THE HYDRAULIC

CONNECTIONS

General

1. Make sure the fittings and O-rings being used are the

proper size and style.

2. Flush the sealing surfaces with clean hydraulic oil to

remove any dirt.

3. Carefully inspect the threads and sealing surfaces for

nicks, gouges, and other damage. Do not use damaged

parts. They will leak.

4. Carefully inspect O-rings for cuts and other damage. Do

not use damaged O-rings. They will leak.

5. Lubricate O-rings when assembling them to fittings.

6. Be careful not to cut O-rings when assembling them to

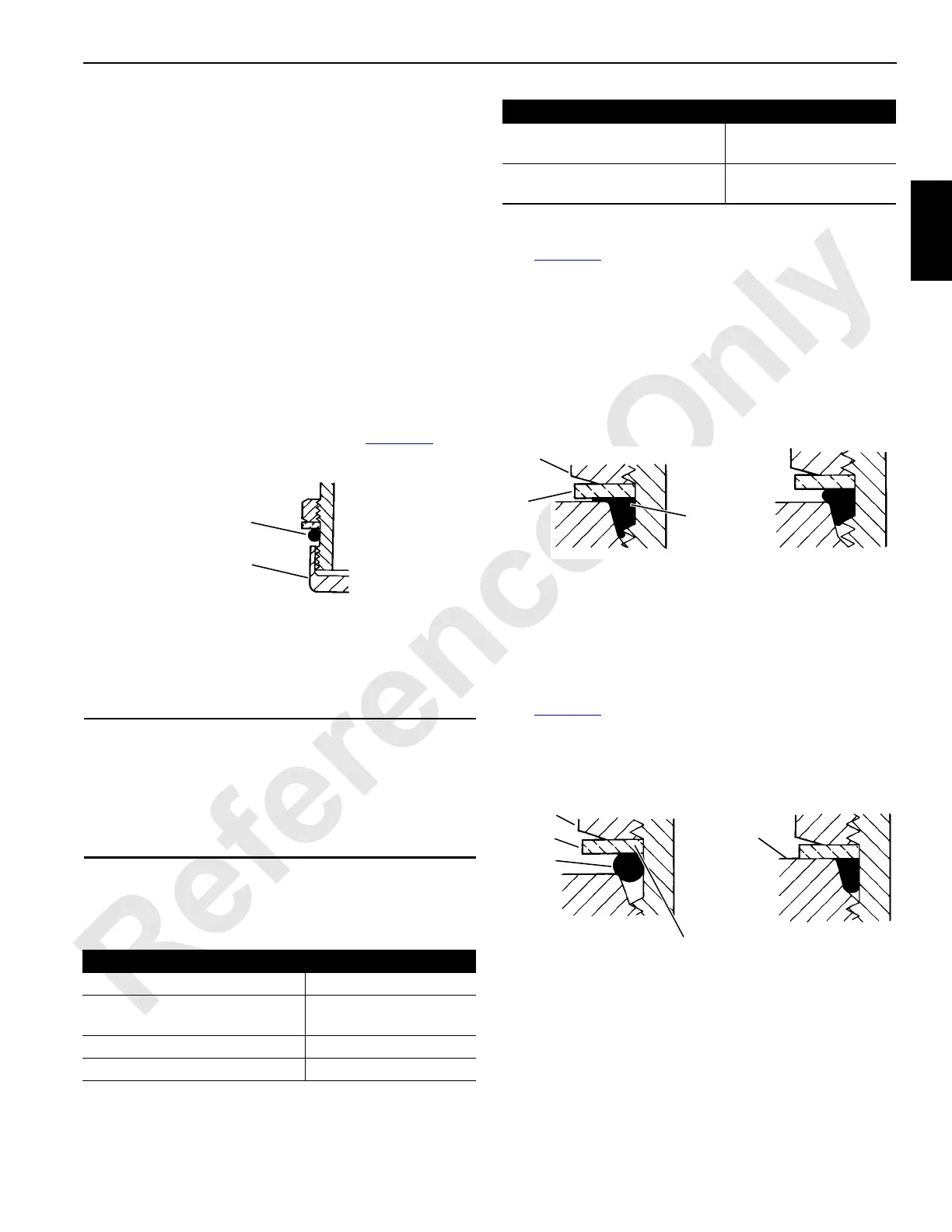

fittings. Use a thimble as shown in Figure 2-4

when

assembling an O-ring over threads.

Pipe Thread Connection

1. Apply sealant (Loctite 92 or equivalent) to male threads,

never to female threads. Do not apply sealant to the first

two male threads.

2. Tighten fittings about 4-1/2 turns by hand and then 3

additional turns with a wrench.

Table 2-3. Pipe Thread Leakage

SAE Straight Thread Connection

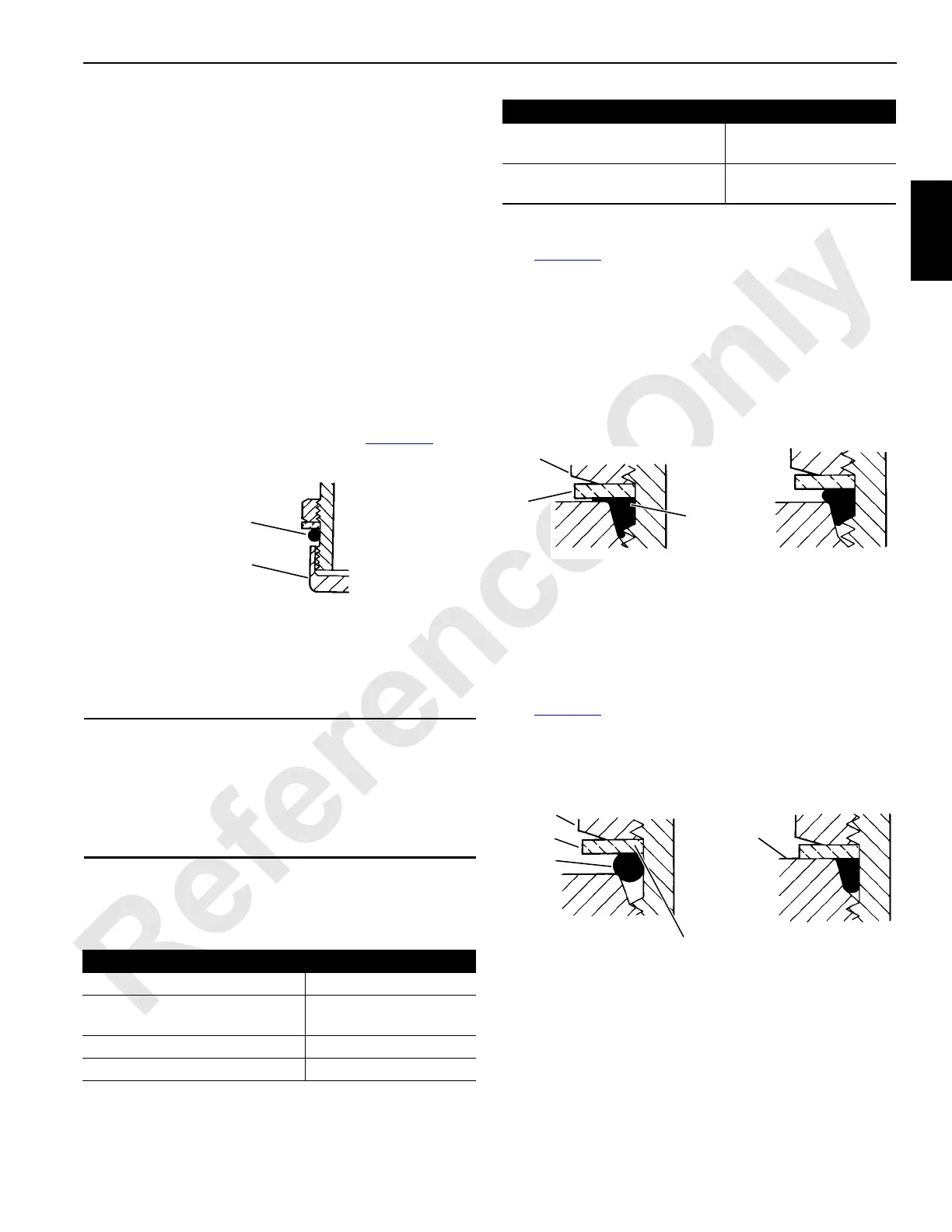

See Figure 2-5 for the following.

This type of connection leaks most often because the jam

nut and washer are not backed up before assembly.

As shown in View A, when the jam nut and washer are not

backed up, there is not enough room for the O-ring when the

squeeze takes place and the washer cannot seat properly.

As shown in View B, the compressed rubber between the

washer and the spot face will cold flow out of compression,

causing the fitting to loosen and leak.

See Figure 2-6

for the following procedure.

Tighten SAE straight thread connections, as follows.

1. Back up the jam nut and washer to the end of the

smooth portion on the fitting (View A).

2. It is important to lubricate the O-ring with clean oil.

3. Thread the fitting into the port until the washer bottoms

against the spot face (View B).

NOTE: If an elbow is being used, back it out as necessary

to align it with the hose.

CAUTION

Hydraulic System Damage!

Debris can contaminate and damage the hydraulic

system.

Do not use FTE-fluorocarbon tape to seal threads. Pieces

of tape will enter the hydraulic system and cause damage.

Cause Cure

Fitting loose Tighten

Fitting too tight causing thread

distortion

Replace damaged parts

Fitting or port threads wrong size Use proper size threads

Threads dirty, galled, or nicked Clean or replace parts

FIGURE 2-4

S103

Plastic or Metal Thimble

Covering Threads

O-ring

Straight thread used instead of

tapered thread

Use proper type and size

thread

Female threads expanded from

heat

Tighten when hot

Cause Cure

FIGURE 2-5

The washer cannot seat properly

on the spot face. Compressed

rubber between the washer and

spot face will cold flow out of

compression, causing the fitting

to loosen and leak.

When the jam nut and washer

are not backed up, there is not

enough room for the O-ring

when the squeeze takes place.

S107

Jam Nut

O-ring

Washer

View A View B

FIGURE 2-6

Nut and washer backed up to end

of smooth portion on fitting.

S106

Jam Nut

Washer

O-ring

Spot Face

View A View B

Loading...

Loading...