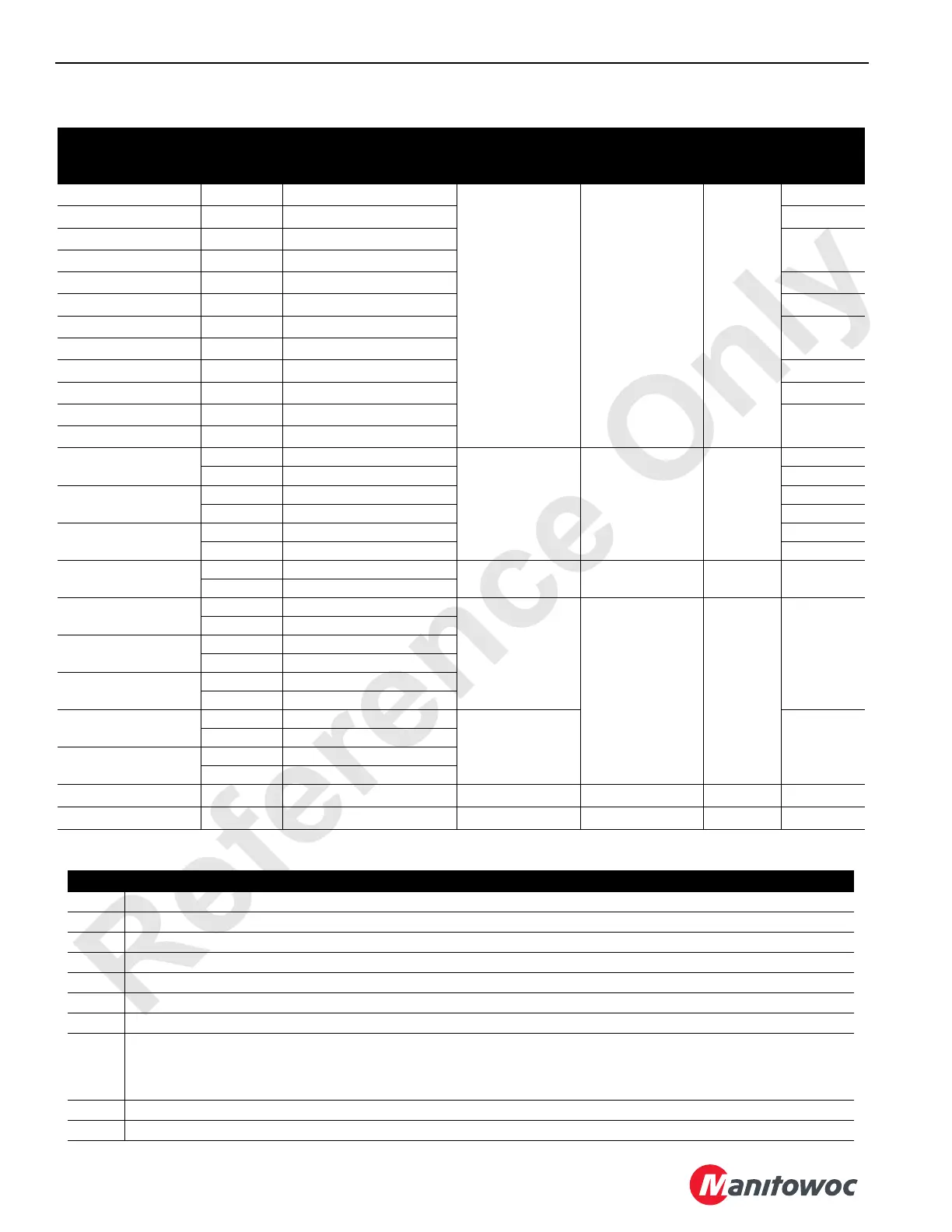

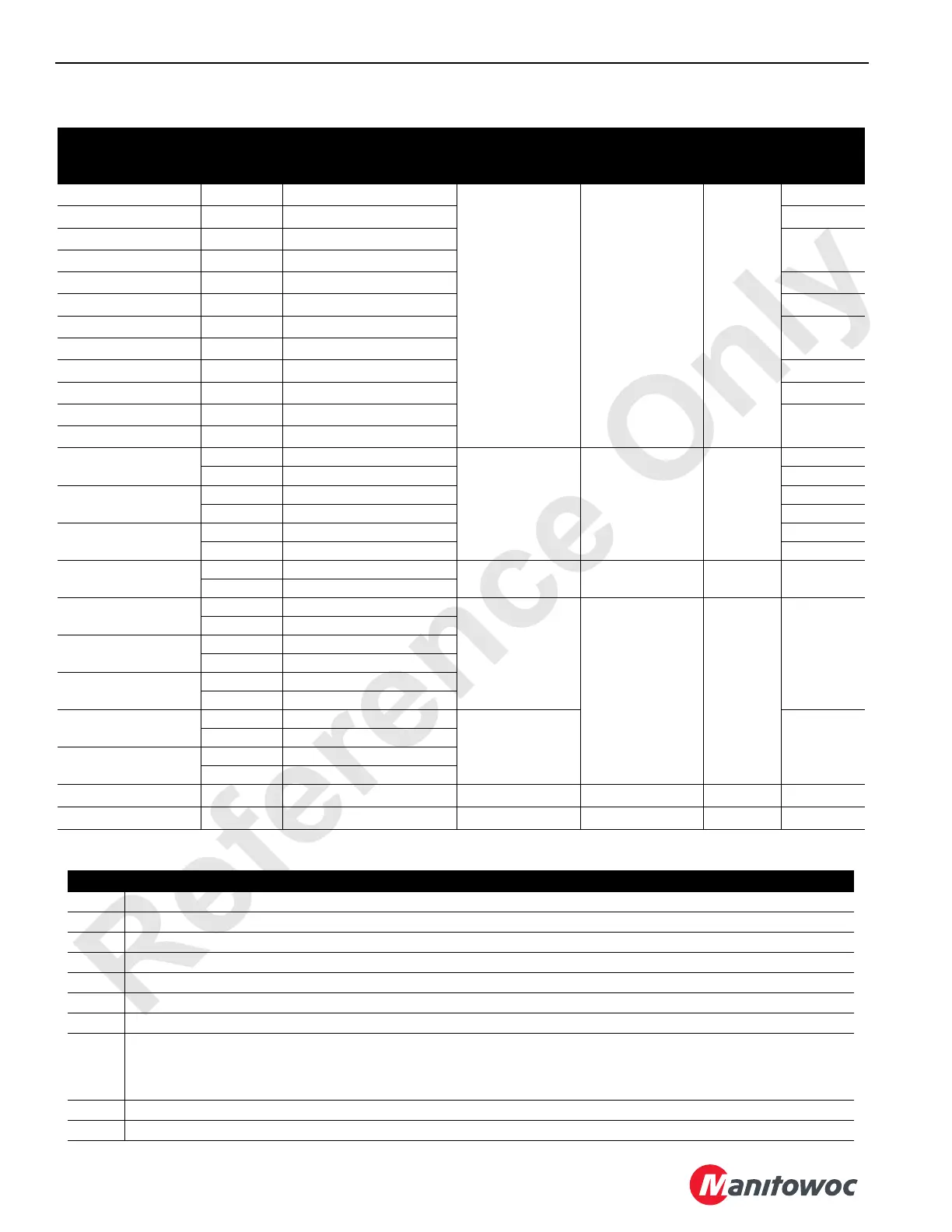

Function Direction

Pump-Motor Port

Connections

System

Pressure 1

1

bar (psi)

System

Pressure 2

2

bar (psi)

Charge

Pressure

bar (psi)

Speed

3

rpm

Drum 1

9

Low Speed

Lower Pump B to Motor B

200 (2,900) Lower

420 (6,090) Hoist

N/A 24 (350)

40 to 48

Drum 1

9

Low Speed

Hoist Pump A to Motor A

45 to 50

Drum 1

9

High Speed

Lower Pump B to Motor B

50 to 56

Drum 1

9

High Speed

Hoist Pump A to Motor A

Drum 2

4

Low Speed

Lower Pump B to Motor B

40 to 48

Drum 2

4

Low Speed

Hoist Pump A to Motor A

45 to 50

Drum 2

4

High Speed

Lower Pump B to Motor B

50 to 56

Drum 2

4

High Speed

Hoist Pump A to Motor A

Drum 3

4

Low Speed

Lower Pump B to Motor B

40 to 48

Drum 3

4

Low Speed

Hoist Pump A to Motor A

45 to 50

Drum 3

4

High Speed

Lower Pump B to Motor B

50 to 56

Drum 3

4

High Speed

Hoist Pump A to Motor A

Boom Hoist

Drum 4

5

Lower Pump B to Motor A

200 (2,900) Lower

420 (6,090) Hoist

N/A 24 (350)

14 to 17

Hoist Pump A to Motor B 16 to 18

Luffing Jib Hoist

Drum 5

5

Lower Pump B to Motor B 34 to 40

Hoist Pump A to Motor A 38 to 42

MAX-ER Main Hoist

Drum 9

6

Lower Pump B to Motor A 38 to 46

Hoist Pump A to Motor B 43 to 48

Rigging Winch

Haul In N/A

204 (3,000) N/A N/A 85 to 90

Pay Out N/A

Swing Single Drive

Left Pump A to Motor A

420 (6,090)

Right or Left

N/A 24 (350)

1.1 to 1.5

Right Pump B to Motor B

Swing Dual Drive

7

Left Pump A to Motors A

Right Pump B to Motors B

Swing Dual Drive High

Speed

7

Left Pump A to Motors B

Right Pump B to Motors A

Left Side Travel

6

Forward Pump B to Motor A

420 (6,090)

Forward or Reverse

8 to 9

at Tumbler

Reverse Pump A to Motor B

Right Side Travel

6

Forward Pump B to Motor A

Reverse Pump A to Motor B

Accessory Pumps

8

N/A Open Loop to Tank

N/A 0 to 241 (0 to 3,500) N/A N/A

Fan Pump

10

N/A Open Loop to Tank

224 (3,250)

Notes

1 This is controlled by multi-function valves in each pump.

2 This is controlled by the crane’s programmable controller.

3 Speeds are based on engine at high idle, no load (no rope on drums), and handles moved fully forward or back.

4 The same pump is used for split rear drum 2 or 3. The active drum is selected by the first handle moved.

5 This is the pump used for Boom Hoist 4 or Luffing Jib Hoist 5. The active drum will not hoist until the alternate drum is parked.

6 These are the pumps used for MAX-ER Main Hoist Drum 9 or travel left side and right side.

7 Dual swing standard with MAX-ER 2000 prep. High-speed swing motors optional for clamshell operation.

8

Accessory pumps are the source of hydraulic pressure for the accessory system and high-pressure accessory components. Items

include swing and travel brakes, boom hinge pin cylinders, rotating bed jacking cylinders, front and rear adapter frame pin cylinders,

mast pins and raising cylinders, cab tilt cylinder, rigging winch, crawler pin cylinders, and MAX-ER 2000. The computer controls pump

pressure depending on the accessory selected.

9 Optional Front Drum 1 is not present in MAX-ER configuration.

10 The fixed-displacement fan pump also supplies low pressure to MAX-ER Drum 9 accessory.

Loading...

Loading...