POWER TRAIN 2250 SERVICE/MAINTENANCE MANUAL

7-2

Published 07-19-16, Control # 249-01

Multiple-Battery System

In a multiple-battery system, the batteries are connected

either in series or in parallel. Always refer to your wiring

diagram for the correct connection.

NOTE: Installing the batteries with reversed electrical

connections will damage the batteries and also the

crane’s electrical system, the voltage regulator,

and/or the alternator.

Maintenance

Weekly—Checking the Electrolyte Level

1. Clean the top of the battery before removing the vent

caps. Take care to not allow dirt to enter the cells.

2. Use distilled water for replenishing the battery. Drinking

water is satisfactory, but do not use water with a high

mineral content (such as well, creek, or pond water).

3. Never overfill the cells. Overfilling will cause the

electrolyte to pump out, and corrosion damage will

result.

Immediately clean and neutralize any acid spills on

painted or metal surfaces with sodium bicarbonate

(baking soda) or ammonia.

4. Look for heavy deposits of a black, lead-like mineral on

the bottom of the vent caps. This indicates that an active

material is being shed (a result of overcharging).

An excessive amount of water consumption also

indicates overcharging.

5. Sulfuric acid must never be added to a cell unless it is

known that acid has been spilled out or otherwise lost—

consult your battery dealer for instructions.

Every 2 Months—Testing the Batteries

NOTE: Before testing a battery, determine that the

alternator is putting out current, that the current is

flowing to the battery, and that the voltage delivered

is within acceptable limits.

Hydrometer Test

1. The electrolyte level in each cell must be at its proper

height to get reliable readings.

2. Readings should not be taken immediately after water is

added. The solution must be thoroughly mixed by

charging.

3. Readings should not be taken after a battery has been

discharged at a high rate, such as from cranking.

4. When reading a hydrometer, hold the barrel vertical with

the float freely suspended.

5. Draw the electrolyte in and out several times to bring the

float temperature to that of the electrolyte.

6. Take the reading across the bottom of the liquid level.

Disregard the curvature of the liquid.

7. Readings must be temperature-corrected. Subtract

0.004 from the reading for each 10° below 80°F. Add

0.004 for each 10° above 80°F.

NOTE: It is the electrolyte temperature that is important,

not the air temperature.

8. See Table 7-2

for the following.

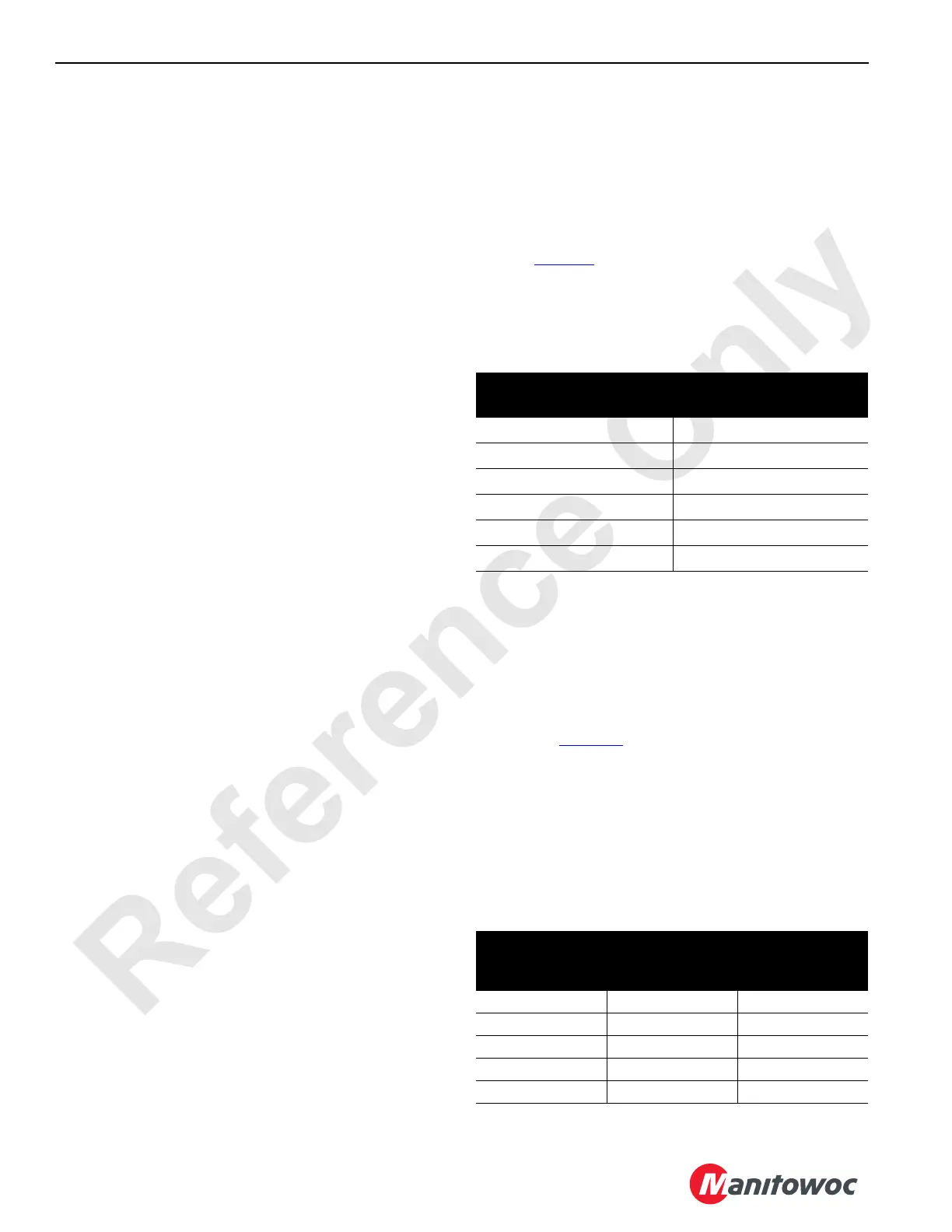

Table 7-2. Hydrometer Readings

Temperature-corrected hydrometer readings may be

interpreted as follows:

If any two cells show more than 50 points (0.050 specific

gravity) variation, try to recharge the battery. If the variation

persists, the battery should be replaced.

For more specific hydrometer test information, see the

instructions provided with your hydrometer.

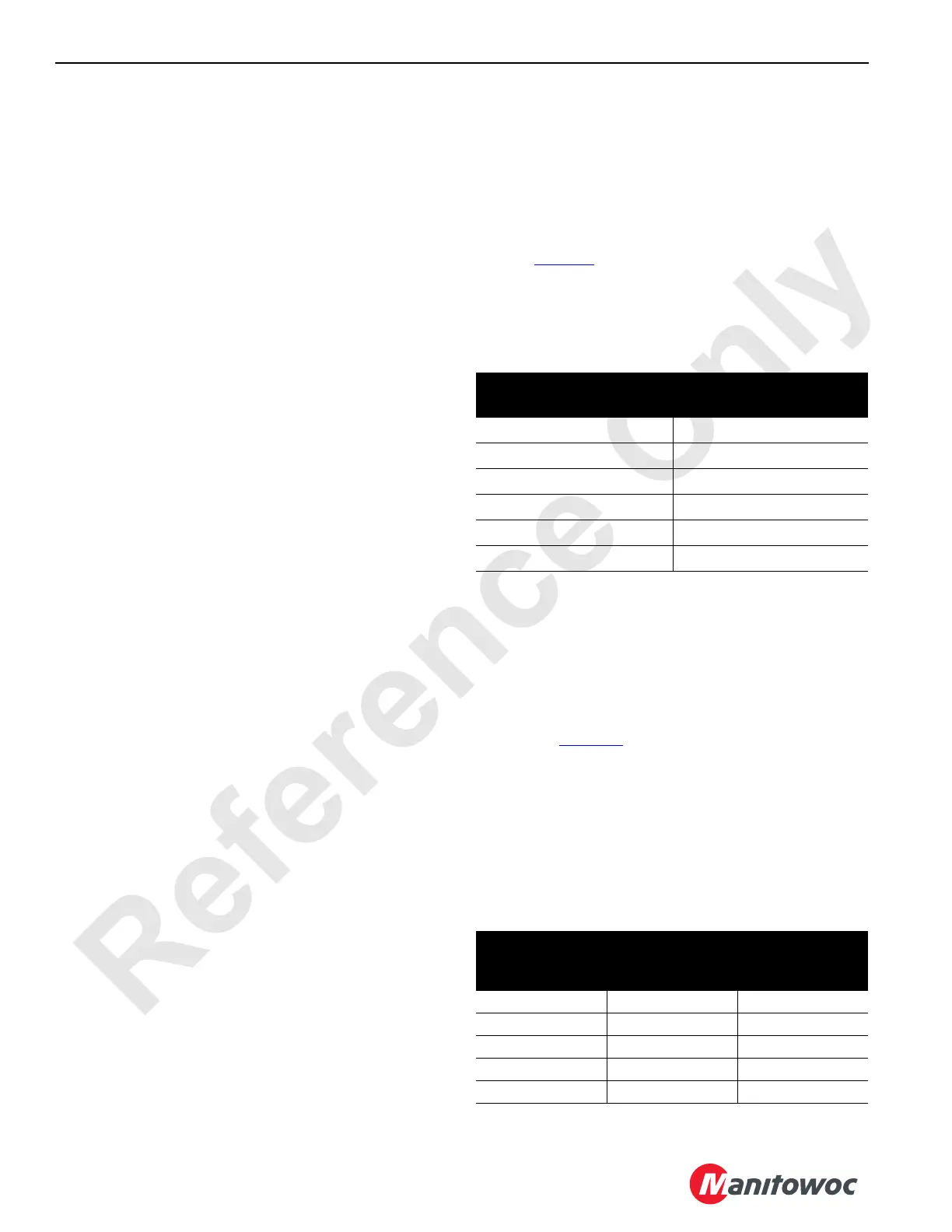

Open Circuit Voltage Test

A voltmeter can be used to determine a battery’s state of

charge. See Table 7-3

for the following.

The open circuit test is not as reliable in determining a

battery’s condition as the hydrometer test. This test is

acceptable for stored batteries, but not ones in use.

This test must not be performed on batteries being charged

or delivering power. Charging causes an increase in voltage,

which may persist for an extended period.

Table 7-3. Open Circuit Cell Voltage

Hydrometer Reading

Specific Gravity

% Charge

1.260 – 1.280 = 100

1.230 – 1.250 = 75

1.200 – 1.220 = 50

1.170 – 1.190 = 25

1.140 – 1.160 = Very little useful capacity

1.110 – 1.130 = Discharged

% Charge Specific Gravity

Approximate

Open Circuit Cell

Voltage

100 1.260 2.10

75 1.230 2.07

50 1.200 2.04

25 1.170 2.01

Discharged 1.110 1.95

Loading...

Loading...