Manitowoc Published 07-19-16, Control # 249-01 2-41

2250 SERVICE/MAINTENANCE MANUAL HYDRAULIC AND AIR SYSTEMS

Maintenance

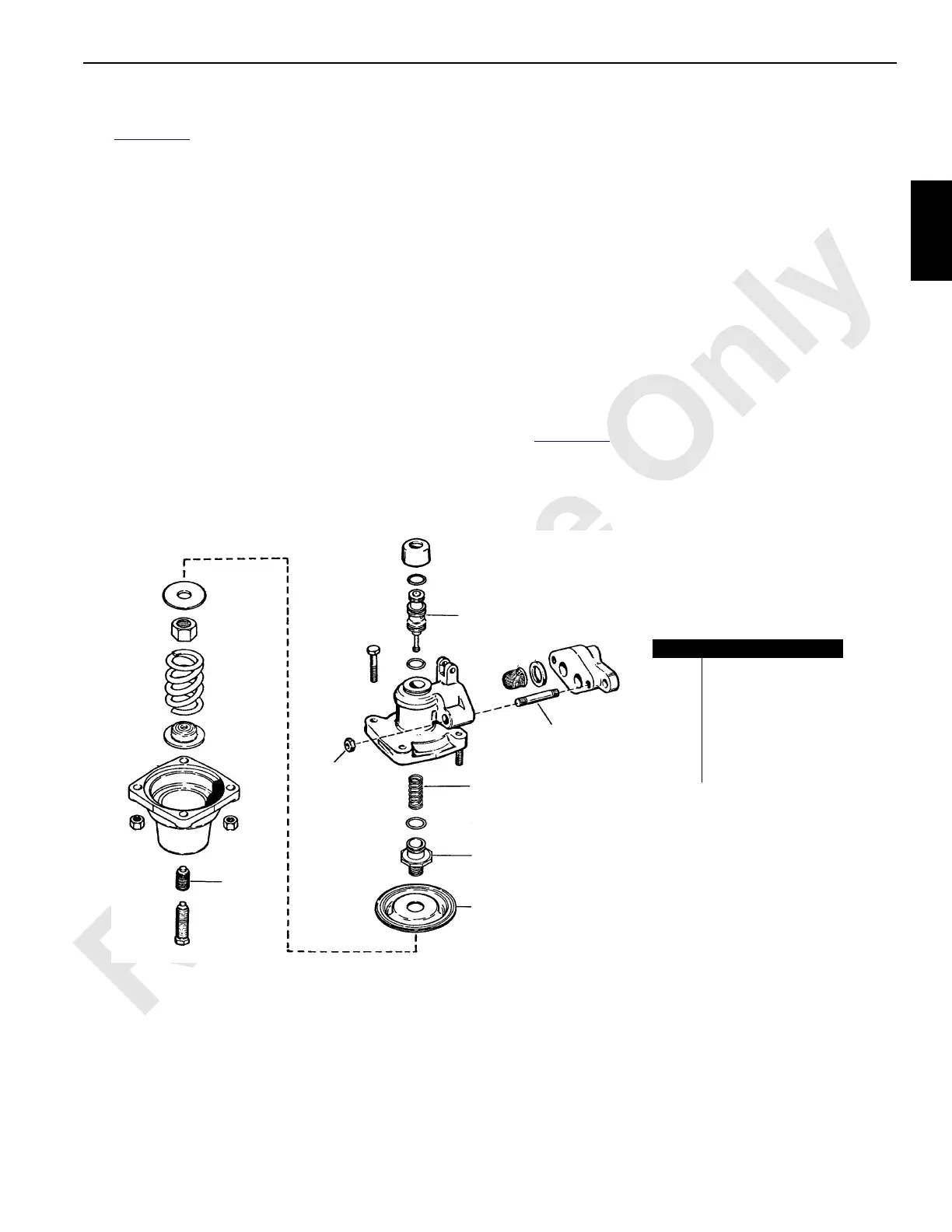

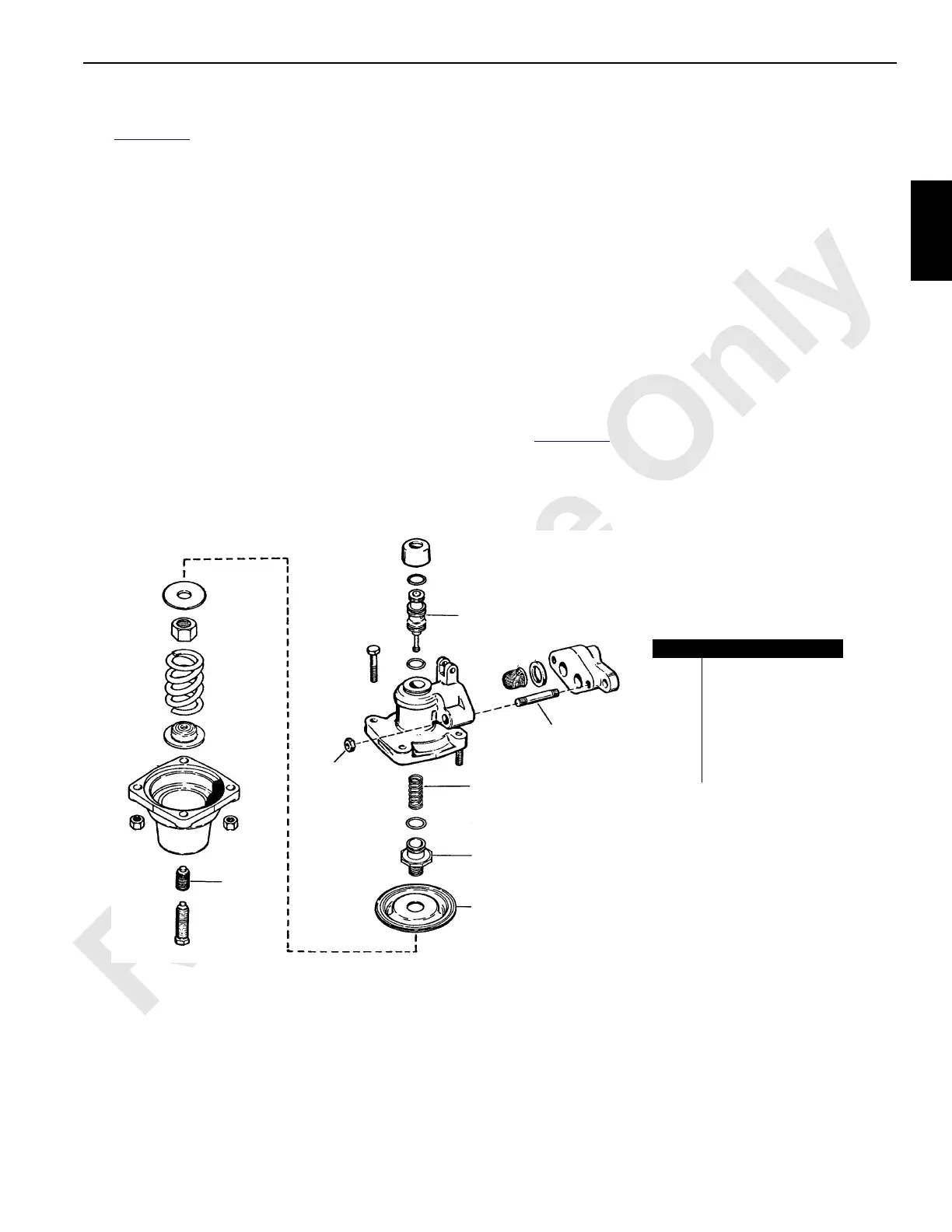

See Figure 2-45 for the following procedure.

Maintenance periods should be scheduled in accordance

with the frequency of use and working conditions of the

valve.

One complete valve should be kept in stock for each four

valves in service. During the maintenance period, change

out the complete valve with the standby unit. This will reduce

production time loss and allow inspection and replacement

of worn parts in a clean location at a more convenient time.

NOTE: The operating portion of the valve can be removed

without disturbing the pipe connections.

No special tools are required to maintain the valve.

1. Remove the valve portion by loosening the nut (5) and

stud (6).

2. Completely disassemble the valve.

3. Wash all metal parts in a nonflammable solvent and all

rubber parts in soap and water.

4. Rinse each part thoroughly and blow dry them with a

low-pressure air jet.

5. Arrange the parts on a clean surface in the order of the

exploded view.

6. Examine each part carefully. Flex the diaphragm and

packing rings, and if cracked or worn, replace them.

Replace all parts that may not provide satisfactory

service until the next maintenance period.

7. Reassemble the valve using the exploded view as a

guide. Lubricate each part before it is put into place. Use

No. 107 Lubriplate on all metal-to-metal surfaces and

No. 55 Pneumatic Grease on all rubber parts. Equivalent

greases to those recommended can be used.

8. Store the reconditioned valve in a moisture-proof bag.

Adjustments

See Figure 2-45 for the following procedure.

Use the adjusting screw (7) to adjust the valve. Turn the

adjusting screw in to raise the outlet pressure, and turn it out

to lower the outlet pressure.

S120

9

FIGURE 2-45

Item Description

1 Exhaust Valve Unit

2 Control Spring

3 Diaphragm

4 Exhaust Valve Seat

5Nut

6Stud

7 Adjusting Screw

1

2

3

4

5

6

7

Loading...

Loading...