HOISTS 2250 SERVICE/MAINTENANCE MANUAL

5-16

Published 07-19-16, Control # 249-01

INSPECTING AND ADJUSTING THE DRUM

CLUTCH—STANDARD

Description

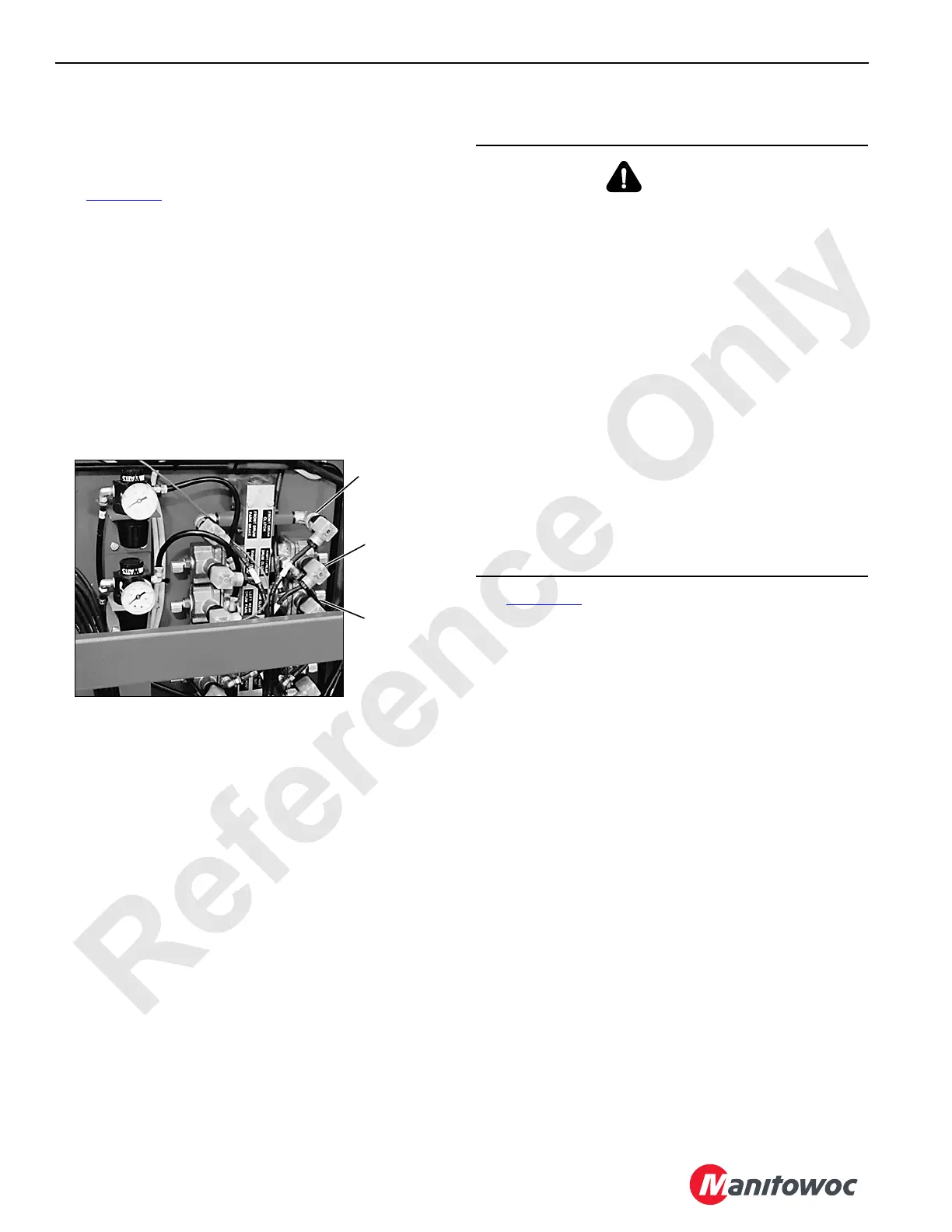

See Figure 5-13 for the following.

The drum clutch is an internal, expanding band-type clutch

that is spring-applied and air-released.

On a single drum shaft, the clutch is mounted on the left end

of the drum. On a split drum shaft, a clutch is mounted on the

outboard end of both drums. Each drum clutch is controlled

by a two-position (on/off) normally closed solenoid valve

located on the left side of the rotating bed.

A clutch access hole with a removable cover is provided in

the guard over each drum brake and clutch. Make all

inspections and adjustments when the clutch linings are

cold.

Inspection and Adjustment

See Figure 5-14 for the following procedure.

Make sure the air system pressure is 8,3 to 9,1 bar (120 to

132 psi) at all times during the inspection and adjustment

procedure.

1. Lower the load block or weight ball to the ground so the

wire rope is slack on the drum being serviced.

2. Select Standard mode and confirm.

3. To position the clutch parts in the access hole during the

inspection and adjustment steps, proceed as follows.

a. Remove the cover from over the access hole (2).

b. Stand clear of the clutch while the drum is turning.

c. Move the drum handle for the clutch being serviced

in either direction from the OFF position to turn the

clutch and drum.

d. When the desired part is accessible through the

access hole, have the adjuster signal the operator to

release the drum handle to the OFF position to stop

the clutch and drum.

4. Position the live end of the clutch band in the access

hole and inspect the lining (16) wear.

The clutch lining is 10 mm (3/8 in) thick when new.

Replace the lining before its thickness is less than 6 mm

(1/4 in), or the lining rivets will score the drum.

FIGURE 5-13

Left Rear

Drum Clutch

Solenoid Valves on

Left Side of Rotating Bed

P805

Front Drum

Clutch

(if equipped)

Rear or Right

Rear Drum

Clutch

CAUTION

Moving Machinery Hazard!

It is necessary to rotate the load drum and apply/release

the drum clutch during inspection, adjustment, and

overhaul procedures. This creates a condition in which, if

care is not exercised, minor injury or equipment damage

may occur.

Drum clutch inspection, adjustment, and overhaul

requires two people—one to operate the drum and brake

controls and one to perform the inspection, adjustment,

and overhaul procedures. Maintain constant

communication between the adjuster and operator so the

drum and brake are not operated while the adjuster is in

contact with moving parts.

Lower the load block or weight ball onto the ground so the

wire rope is slack on the drum being serviced.

• The adjuster shall stay clear of all moving parts while

the load drum and clutch are being operated.

• The operator shall not operate the drum controls until

the adjuster is clear of moving parts.

Loading...

Loading...