Manitowoc Published 07-19-16, Control # 249-01 5-9

2250 SERVICE/MAINTENANCE MANUAL HOISTS

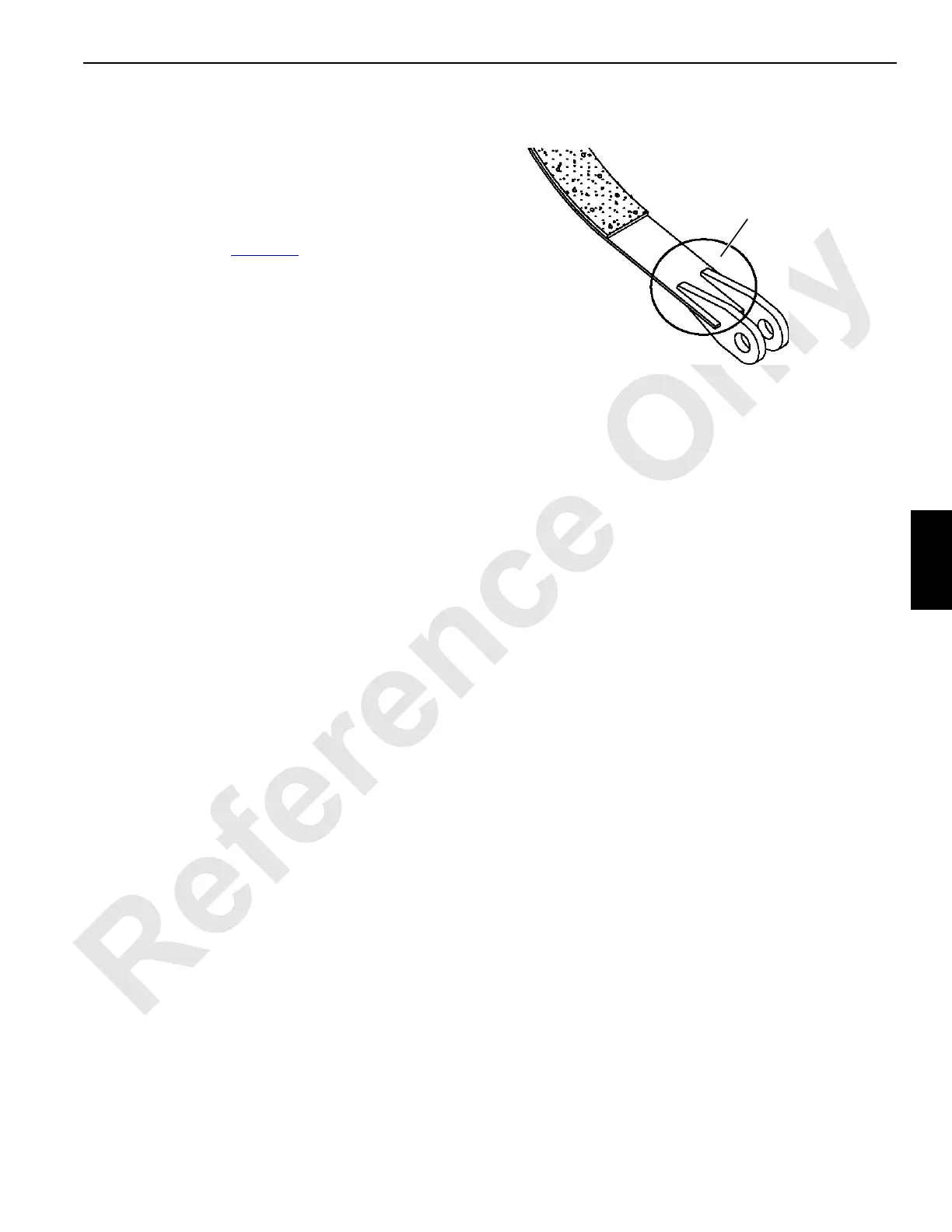

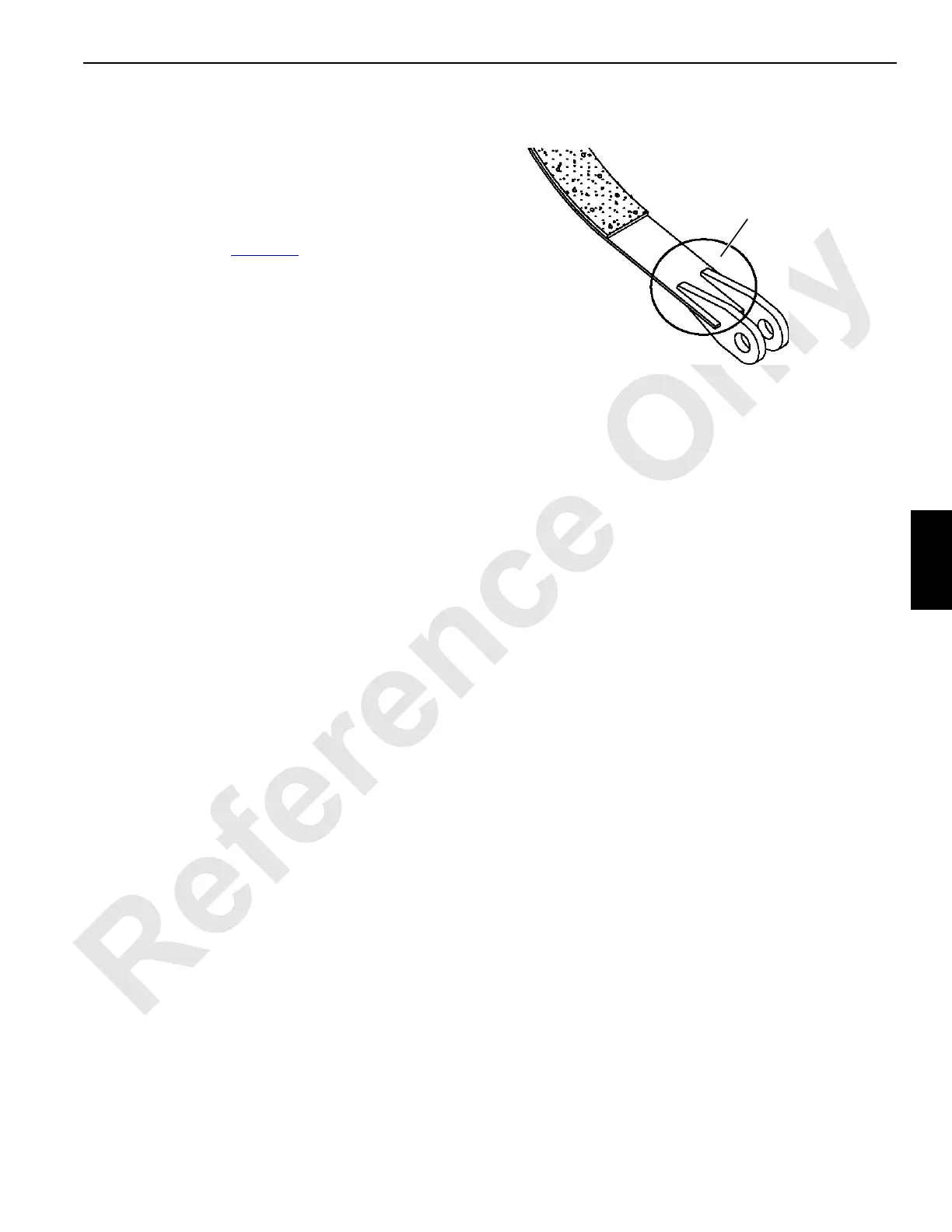

4. Thoroughly inspect the brake bands for cracks and

corrosion when the bands are removed. This procedure

also applies to band assemblies that are received in

exchange for bands that were removed for relining.

The inspection method must include nondestructive

testing—magnetic particle (MT) or ultrasound (UT).

The primary area to inspect is the dead-end attachment

area on the band (Figure 5-7

).

If there is evidence of cracks or a 10% reduction in the

area due to corrosion, destroy and discard the band and

replace it with a new band or a band that has passed

nondestructive testing/inspection. Contact your

Manitowoc Cranes dealer for brake band thickness.

Have the band part number available at the time of the

request.

5. Perform treadle valve checks and make necessary

adjustments.

FIGURE 5-7

Primary Inspection Area

Loading...

Loading...