Manitowoc Published 07-19-16, Control # 249-01 3-25

2250 SERVICE/MAINTENANCE MANUAL ELECTRICAL SYSTEM

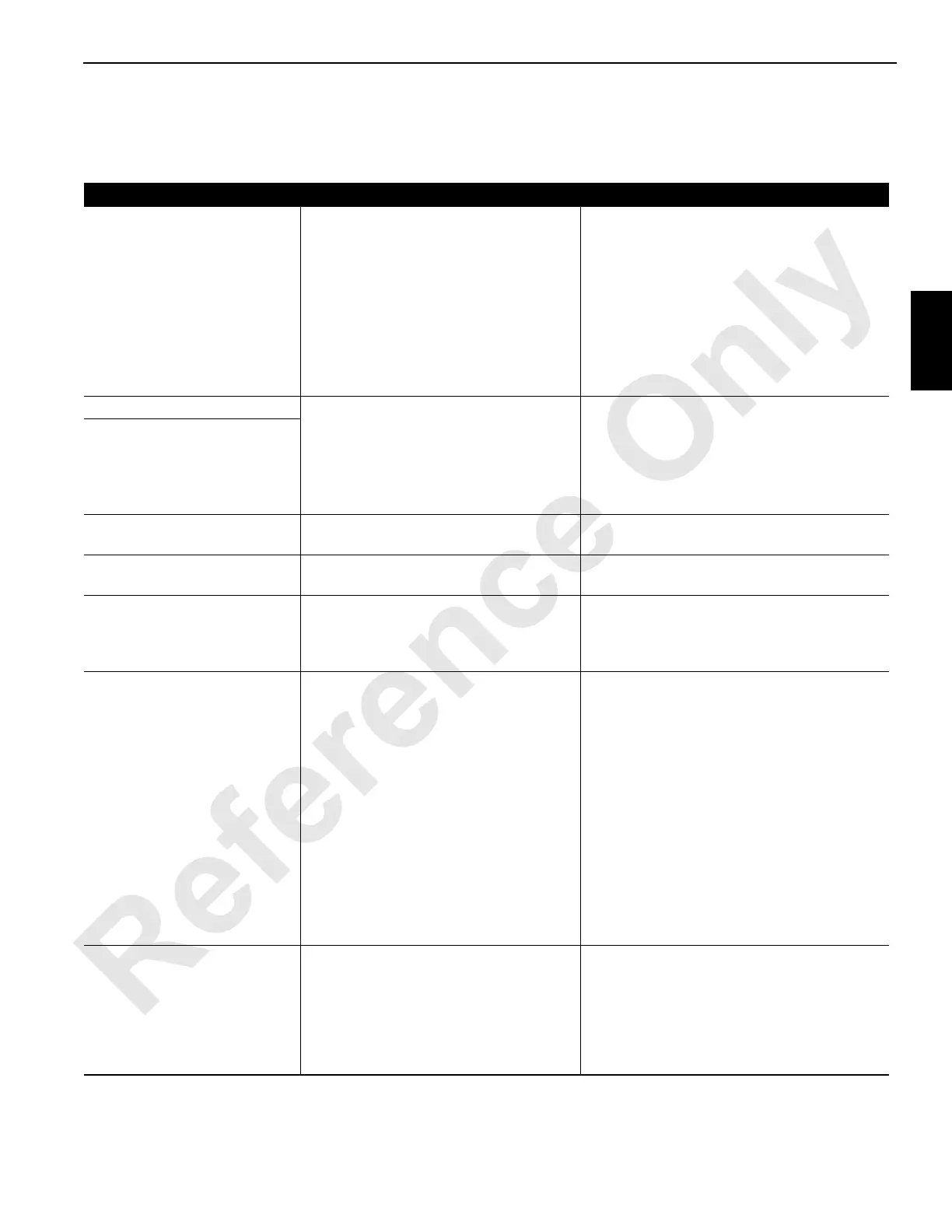

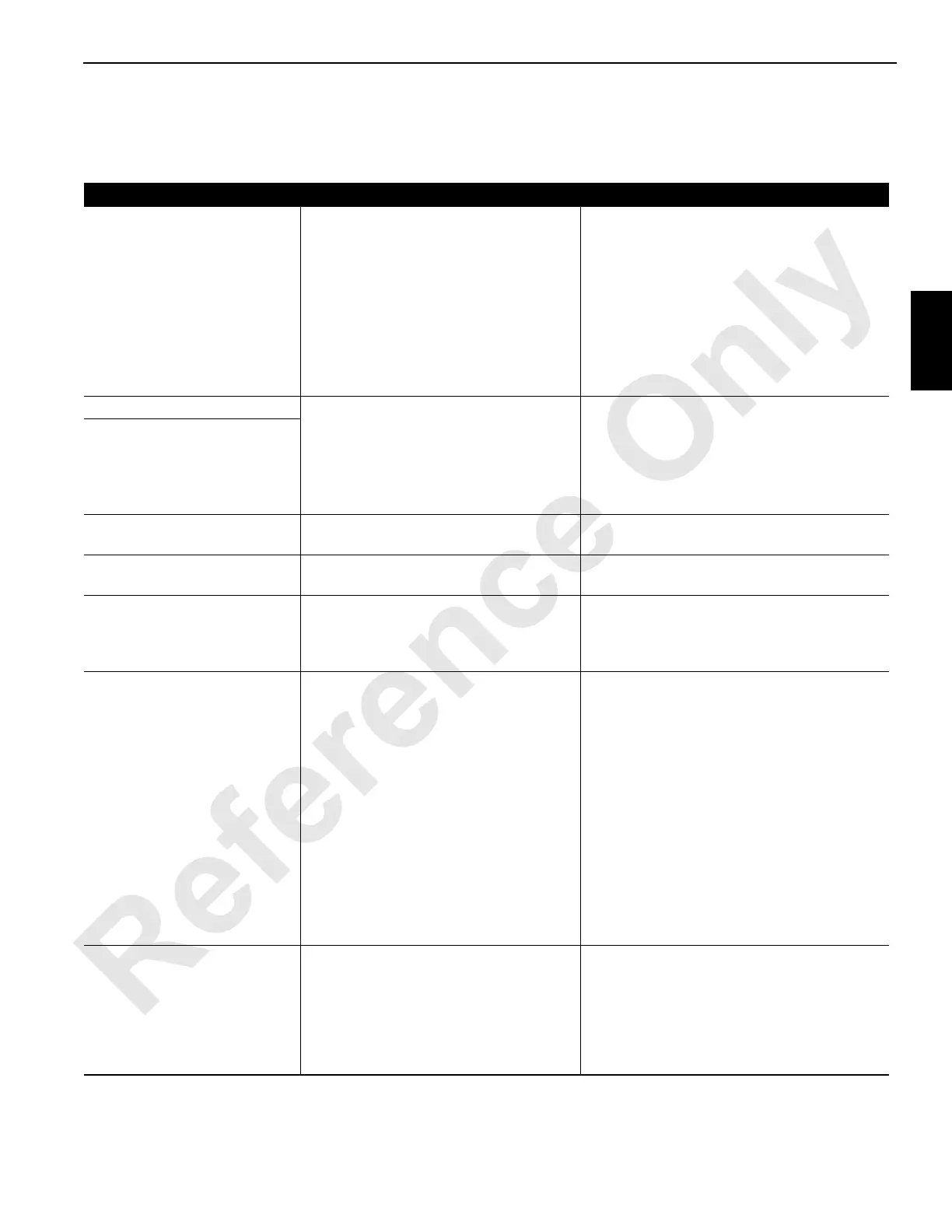

Table 3-4. System Faults

Listed below are the faults that turn on the system fault alert (red light and beeper) in the operator’s cab. When the alert comes

on, scroll to SYSTEM FAULT group of the digital display to determine which fault has been reached. Take corrective action.

Display Reading Cause of Fault Function Response

PUMP 1 CHARGE PRESS Low charge pressure at the load drum

pump.

The load drum brake applies, and the pump

strokes to the neutral position to stop the load

drum. If a drop in charge pressure is

intermittent, operation may be resumed once

the load drum control handle is returned to the

OFF position.

Verify that the cause of the fault is low

pressure and correct the cause as soon as

possible. If the pressure is correct, replace the

pressure sender.

BOOM ANGLE SENDER Sender output voltage 0.0 Volts or above

9.7 Volts.

All functions are operable. The machine level

or boom and luffing jib angle displays will not

be correct. Correct the cause of the sender

fault as soon as possible.

Neither fault is active when the crane is

operated in Setup mode.

* LUFF JIB ANGLE SENDER

LOW AIR PRESSURE Manifold air pressure below 6,2 bar

(90 psi).

If air pressure continues to drop, the load drum

park brakes will apply.

HYD TANK LEVEL Less than 75% level. Stop and check the oil level—fill tank

(reservoir).

LOAD PIN Zero (0) output voltage from the pin. The MAX-ER counterweight stops and

remains in the last position, and the boom

hoist stops and is inoperable in the up

direction.

MOTION A deselected drum turns. If a deselected load drum moves, all drum

brakes and clutches apply, and the pumps

shift to the neutral position to stop all load

drums.

If a selected load drum rotates down when the

handle is in the UP or NEUTRAL position, all

drum brakes and clutches apply and the

pumps shift to the NEUTRAL position to stop

all load drums.

If a deselected boom or luffing hoist drum

moves, the brakes apply and the pumps shift

to the NEUTRAL position to stop both hoists.

Stop and restart the engine to the correct fault

(reboot programmable controller).

* MAX-ER SYSTEM One of the three MAX-ER transducers not

in operating range of 0.6 to 9 Volts.

The differential pressure between the left/

right side strap cylinders is 83 bar

(1,200 psi).

The counterweight tray level is over 3° in

the right or left direction.

The MAX-ER counterweight stops and

remains in the last position.

Check and replace the faulty transducer(s).

Check the hydraulic system and repair.

Level the counterweight tray.

Loading...

Loading...