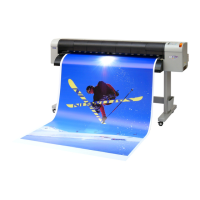

Product overview VJ-1617H OPERATION MANUAL

2-4

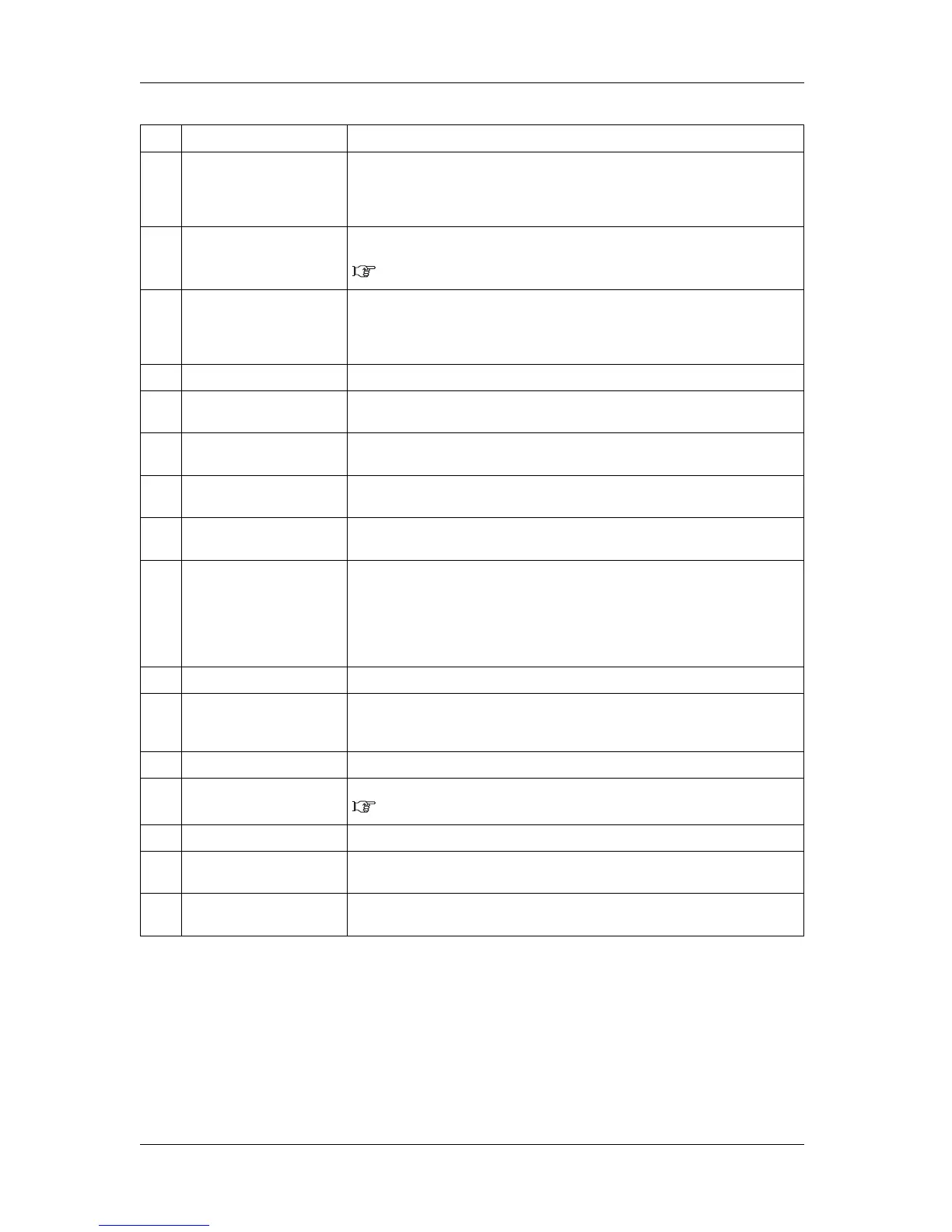

No. Name Function

1 Front media loading lever Used for fixing or releasing the media. The operation is the opposite of Rear media

loading lever on the rear side of the printer.

• Lower Lever to fix the media.

• Raise Lever to release the media.

2 Printer operation panel Operation condition setting, printer display and various function settings are

performed.

2.2.3 Operation panel

3 Front cover Used for preventing a user from coming in contact with the driving mechanism during

the printer operation.

Opened and closed when media is set or jammed.

It is normally closed.

4 Stand Used when installing the printer on a flat floor.

5 Media guide Used for feeding media smoothly when the media is set or printed.

The heater (drier) to dry ink is installed.

6 Platen Installed inside of Front cover.

Holds the media from the bottom during printing.

7 Pressurizing rollers Installed inside of the front cover.

Press and hold the media when printing.

8 Media cut groove Installed inside of the front cover.

Used to cut media straight.

9 Maintenance cover Used to prevent the user from touching the inner mechanical section.

Open and close in the following cases.

• When cleaning the cleaning wiper unit

• When cleaning around the print head

• When performing daily maintenance

It is normally closed.

10 Adjuster Used to install the printer horizontally.

11 Media holder plate Installed inside of Front cover.

Attach them to the both edges of the media to minimize warpage of thin media such

as roll media (with a thickness of less than 0.3 mm) to a degree.

12 Blower heater Blows hot air to accelerate drying of media.

13 Blower heater operation panel Make operational settings and operate Blower heater.

2.2.3.2 Blower hearter operation panel

14 Connecor Used to install the optional spectrophotometer (SPECTROVUE VM-10).

15 Media-feed table Used for feeding thick media smoothly.

Remove it when using roll media.

16 Media stopper If the media you placed on Media-feed table slides down forward, loosen the lug screw

and move Stopper upward. Stopper should normally be facing down.

Loading...

Loading...