SECTION 2

TROUBLESHOOTING

17

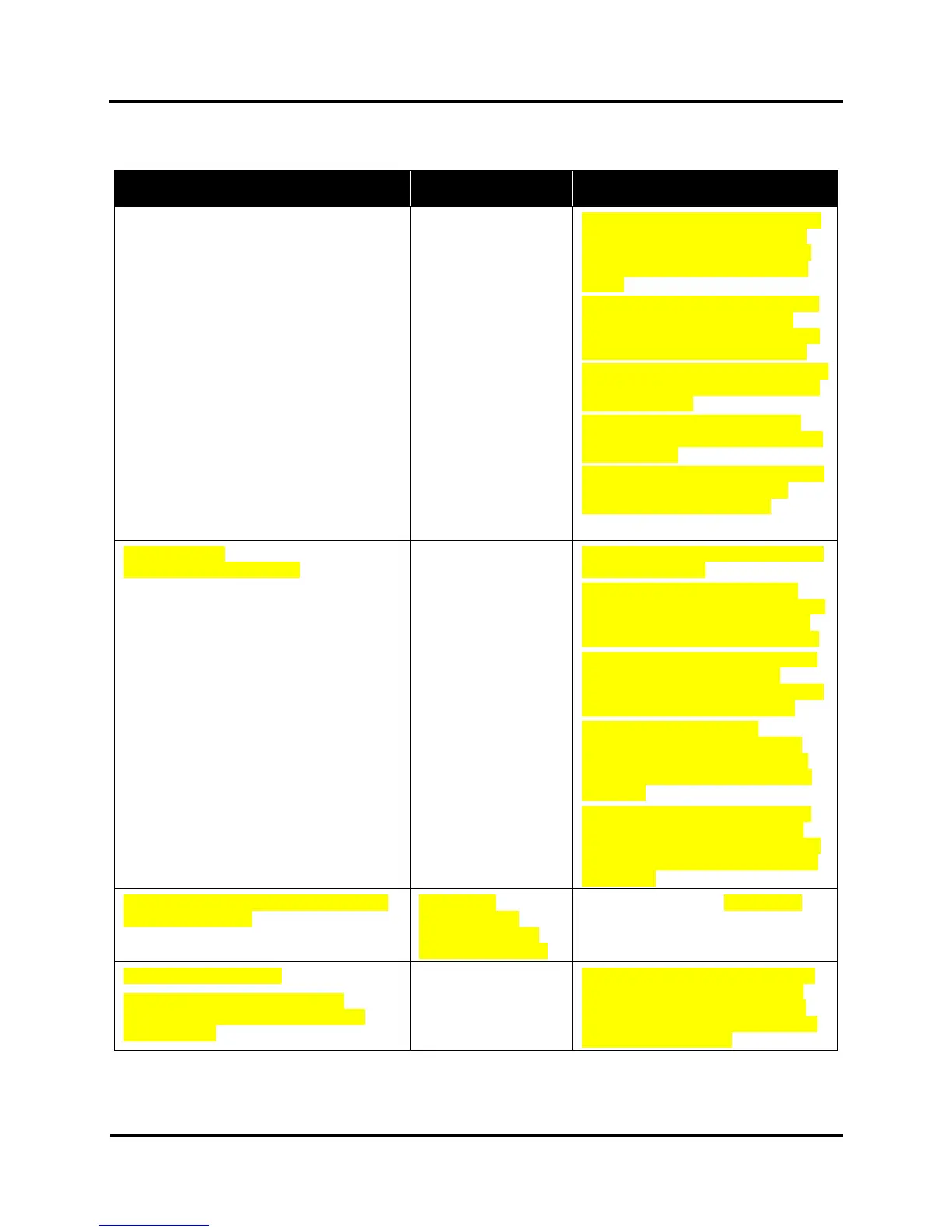

Toolbox System Status Messages (Continued)

SYSTEM STATUS SOURCE SOLUTION

System Status: TILT_ERROR

Printer is not level*.

Printer’s electronics

have detected that

Print Engine is too far

out of level.

Tilt Sensor needs to be

recalibrated.

P2005 unplugged.

*NOTE: Tilt should be

less than

±2 degrees.

If Tilt warning

indicates more than

±2 degrees FB or LR,

(even if Printer

continues to run)

Printer must be

leveled again to

prevent damage or

print issues.

Make sure that the Printer is placed on

a level surface. Failure to do so may

result in severe ink mixing and cause

an inaccurate ink level reading in Ink

Tanks.

If just powered on, wait a few minutes;

error may clear by itself. Once Tilt

Level drops to 1.99 or less, clear error

using “Clear Error” Toolbox button.

Make sure Printer is placed on a sturdy,

level worktable. DO NOT move Printer

while power is on.

If Tilt Level is 1.99 or less, you can

clear this error using the “Clear Error”

Toolbox button.

Contact technical support to have them

check that the Printer is level and

possibly “zero” the Tilt Sensor.

System Status:

MECH_FAIL_PERMANENT

ERROR on System Status screen.

Check the Printer Graphic to determine

what component has a problem or failed:

Service Station, Ink Valve or Printhead,

(usually indicated with a steady “?”)

Mechanical error

One of Printer's

mechanical

components was not

properly registered at

expected position.

Mechanical failure or

Sensor failure.

Visually inspect component stated as a

“Reason” for failure.

Using Scan Sensors screen in the

Printer Toolbox, perform toggle test on

Sensor responsible for registration of

failed mechanical component position.

Lifter Arm Sensor is dirty or damaged,

Lifter Motor Cable is unplugged,

operator's side Lifting Arm is damaged,

or Lifting Arm mechanism is stuck.

Dual Pinch Valve problem:

Check Sensor board connector and

flag/sensors alignment. Check Valve

motor connector. Check P2005 cable

on MPCA.

At this point, this error may represent

an Ink Pump error, since there is no

return signal from pump and therefore,

a separate message describing an Ink

Pump error.

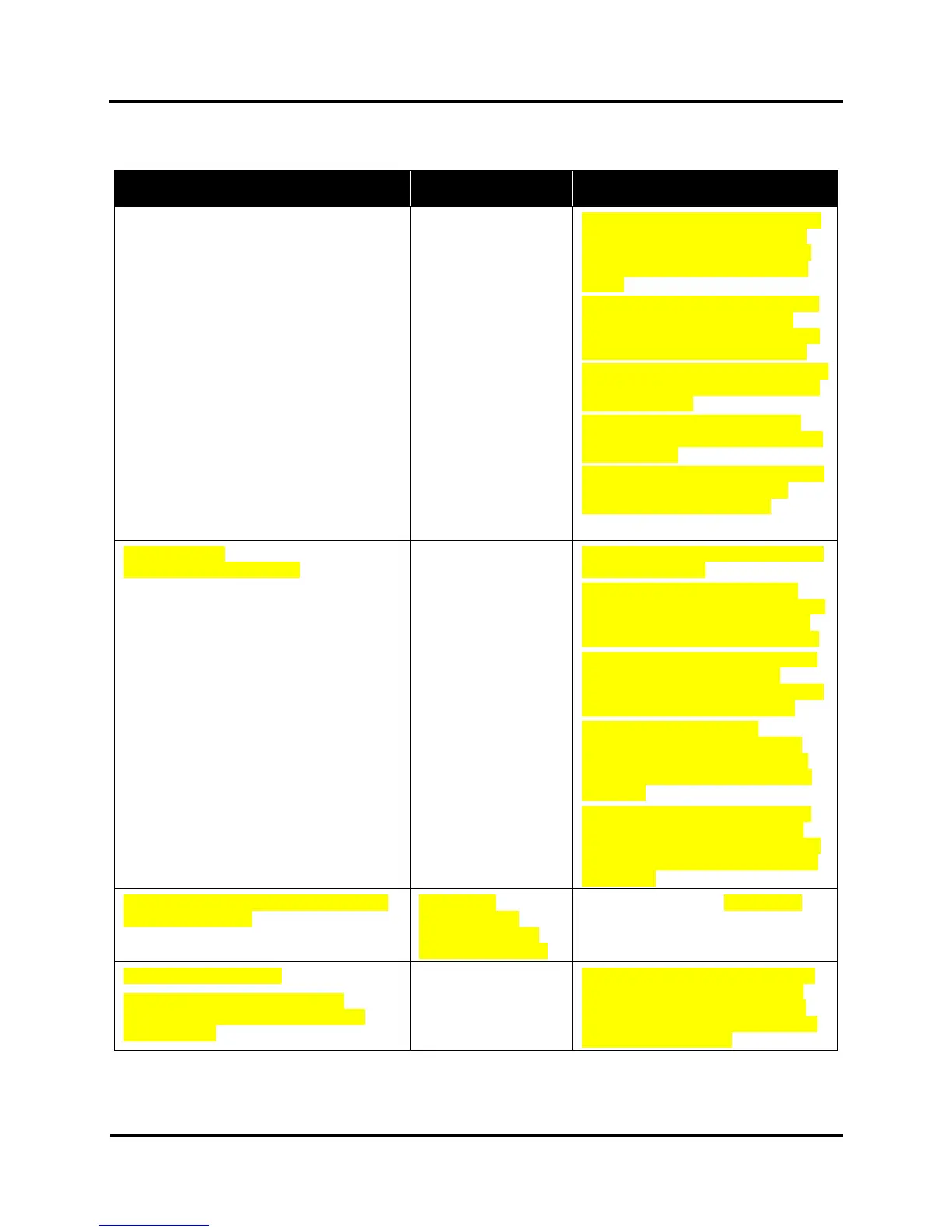

System Status: [Crit 63 03-phead offline

cancelpage restart]

Data Cables

unplugged, dirty

Printhead contacts,

dirty PPCA contacts.

Check the data cables (P250, P260),

clean Printhead contacts, and/or clean

PPCA contacts.

System Status: ONLINE

ERROR on System Status screen.

Printer Graphic shows Printer Service

Station as “?”.

Service Station is

ejected, Service

Station position

sensors are damaged

or malfunctioning.

Check Service Station position. Using

Scan Sensors screen in the Printer

Toolbox, perform toggle test on two

Sensors responsible for registration of

Service Station position.

Loading...

Loading...