3-86

• The parameters n067, n068, and n069 are used for torque compensation.

• It is usually not necessary to change the default-set values.

• Set

n067 to a larger value if

the wiring distance between the Inverter and motor is long and a smaller

value if the motor vibrates.

• Set

with n068 the coil resistance of the motor and n069 the core loss of the motor if the coil resistance

and

core loss are known. The parameters n068 and n069 will probably make the torque boost function

more effective.

n070 Decelerating Stall Prevention Selection

Setting range 0, 1 Unit --- Default setting 1

• Select with n070 a method to process the overvoltage error of the Inverter decelerating the motor.

Set Values

Set value Description

0 Inhibits deceleration stall prevention from functioning.

1 Permits deceleration stall prevention to function.

Note 1. Be

sure to set

n070 to 0 if the Braking Resistor Unit is connected to the Inverter

, otherwise the

Braking Resistor Unit will not work.

Note 2. The

Inverter will automatically extend time to decelerate the motor so that no overvoltage er

-

ror will result if n070 is set to 1.

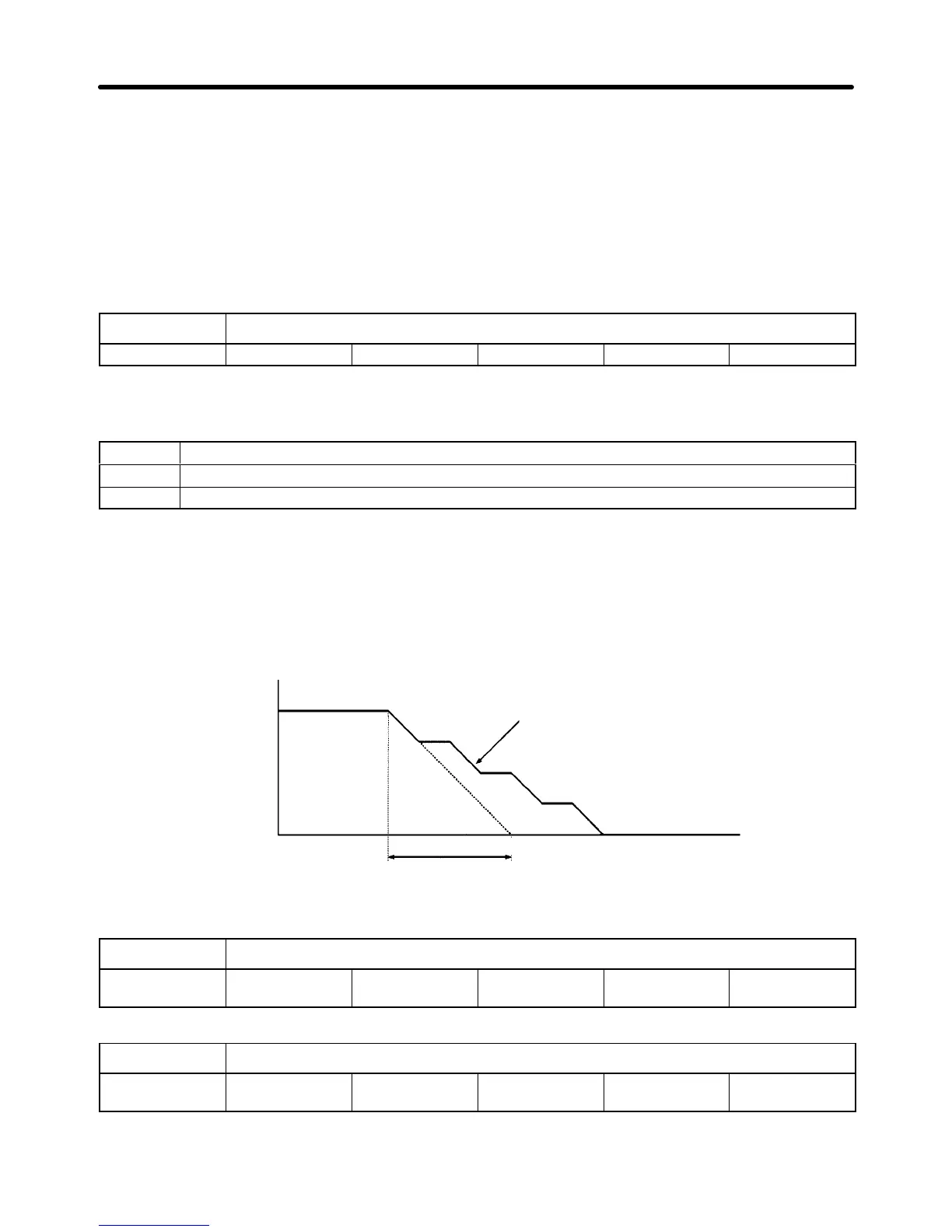

Operation Example

Output

frequency

Deceleration time is controlled

so that no overvoltage error will

result.

Deceleration time

(Set value)

n071 Accelerating Stall Prevention Operation Level

Setting range 30 to 200 Unit % (Rated output

current ratio)

Default setting 170 (See note.)

n072 Operating Stall Prevention Operation Level

Setting range 30 to 200 Unit % (Rated output

current ratio)

Default setting 160 (See note.)

Note The default setting for 18.5-kW or higher Inverters is 120.

Preparing for Operation Chapter 3

Loading...

Loading...