2-32

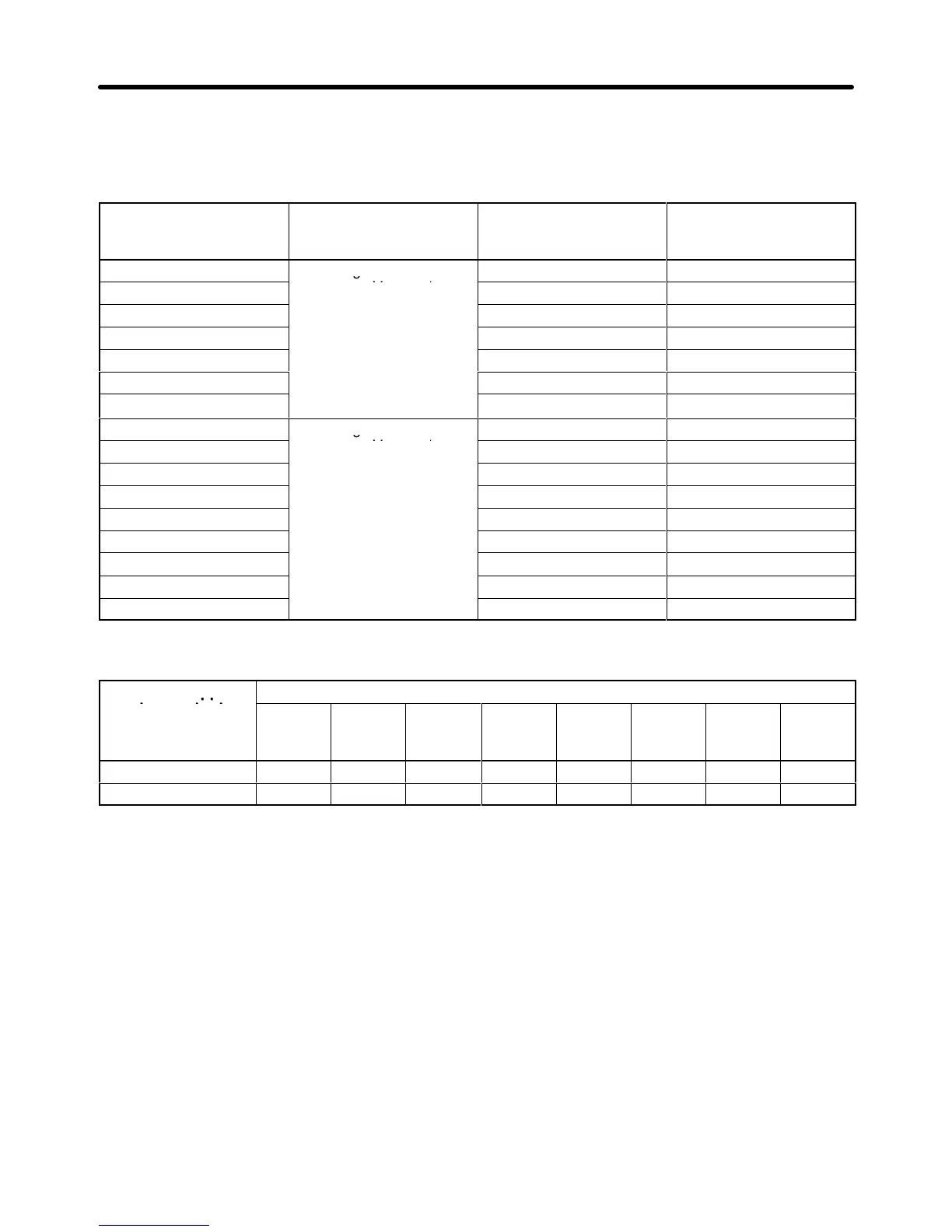

• Input Transformers for 12-pulse Rectification

Refer

to the following table to select the input transformer for 12-pulse rectification. Refer to the mini

-

mum

currents on the secondary winding side in the table

when selecting two standard transformers

used in combination for 12-pulse rectification.

Inverter model

3G3HV-

Input voltage (V) Minimum current on

the primary winding

side (A)

Minimum current on

the secondary winding

side (A)

B2185

I/O voltage ratio: 1:1

100 50

B4450 120 60

B4550 180 80

B4750 206 103

B411K 280 140

B416K 380 190

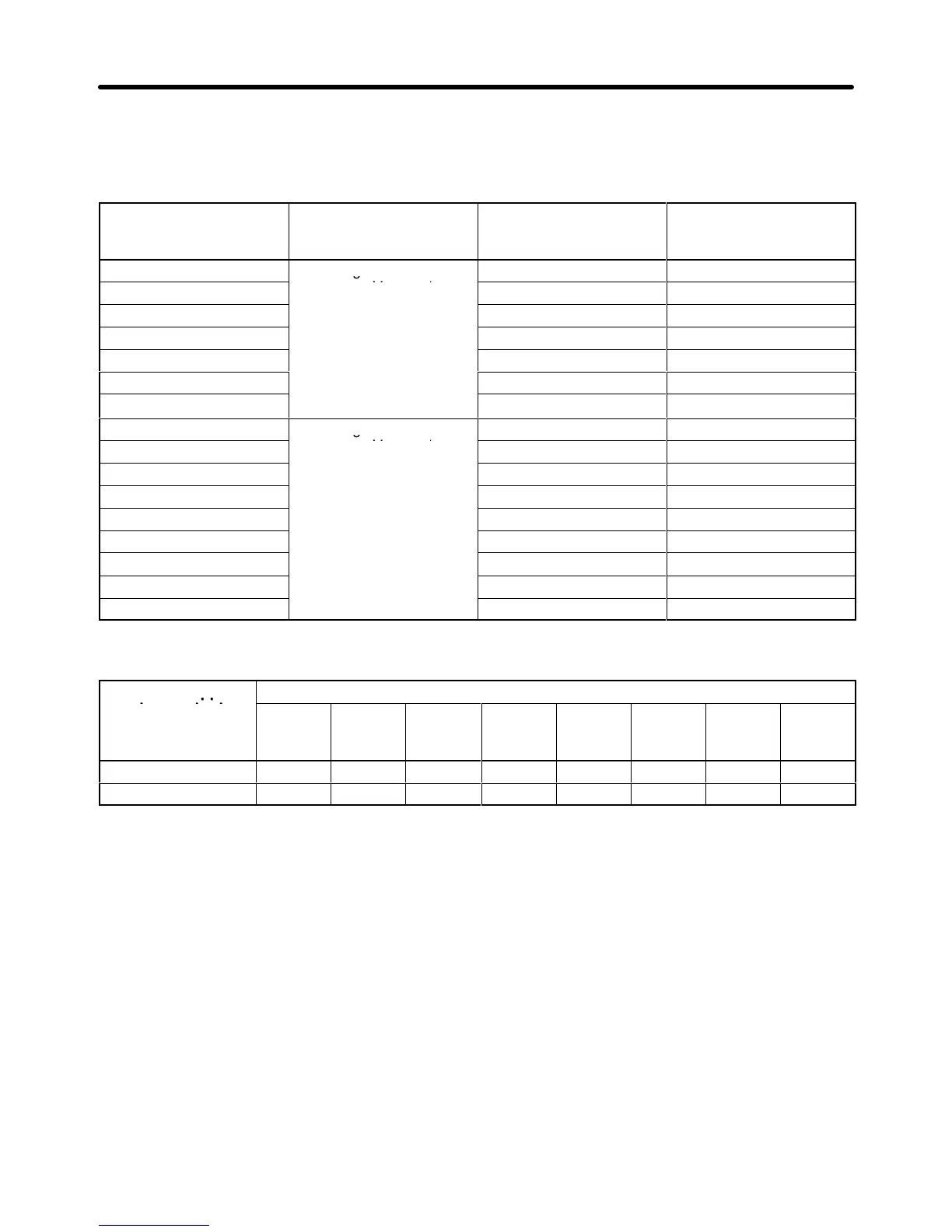

• 12-pulse Rectification Effect

Harmonics are suppressed effectively with 12-pulse rectification as shown in the following table.

Harmonic suppres-

sion method

5th har-

monic

7th har-

monic

11th

harmon-

ic

13th

harmon-

ic

17th

harmon-

ic

19th

harmon-

ic

23th

harmon-

ic

25th

har-

monic

No reactor 65 41 8.5 7.7 4.3 3.1 2.6 1.8

12-pulse rectification 5.43 5.28 5.40 5.96 0.69 0.19 1.49 1.18

H Braking Resistor Unit and Braking Unit

• Connect the Braking Resistor Unit and Braking Unit to the Inverter as shown in the following.

• Set

n079 to 0 (i.e., no overheating protection of the Braking Resistor Unit) and n070 to 0 (i.e., no decel

-

erating stall prevention) before using the Inverter with the Braking Resistor Unit connected.

Note 1. Set n079 to 0 before operating the Inverter with the Braking Resistor Unit without thermal

relay trip contacts.

Note 2. The

Braking Resistor Unit cannot be used and the deceleration time cannot be shortened by

the Inverter if n070 is set to 1 (i.e., decelerating stall prevention).

• To

prevent the Unit from overheating, make a power supply sequence as shown below or connect the

thermal relay trip output of the Unit to the remote error input terminal of the Inverter to interrupt the

operation of the Inverter.

• The Braking Resistor Unit or Braking Unit cannot be connected to the Inverter with an output of

18.5 kW to 160 kW.

Installation Chapter 2

Loading...

Loading...