3-87

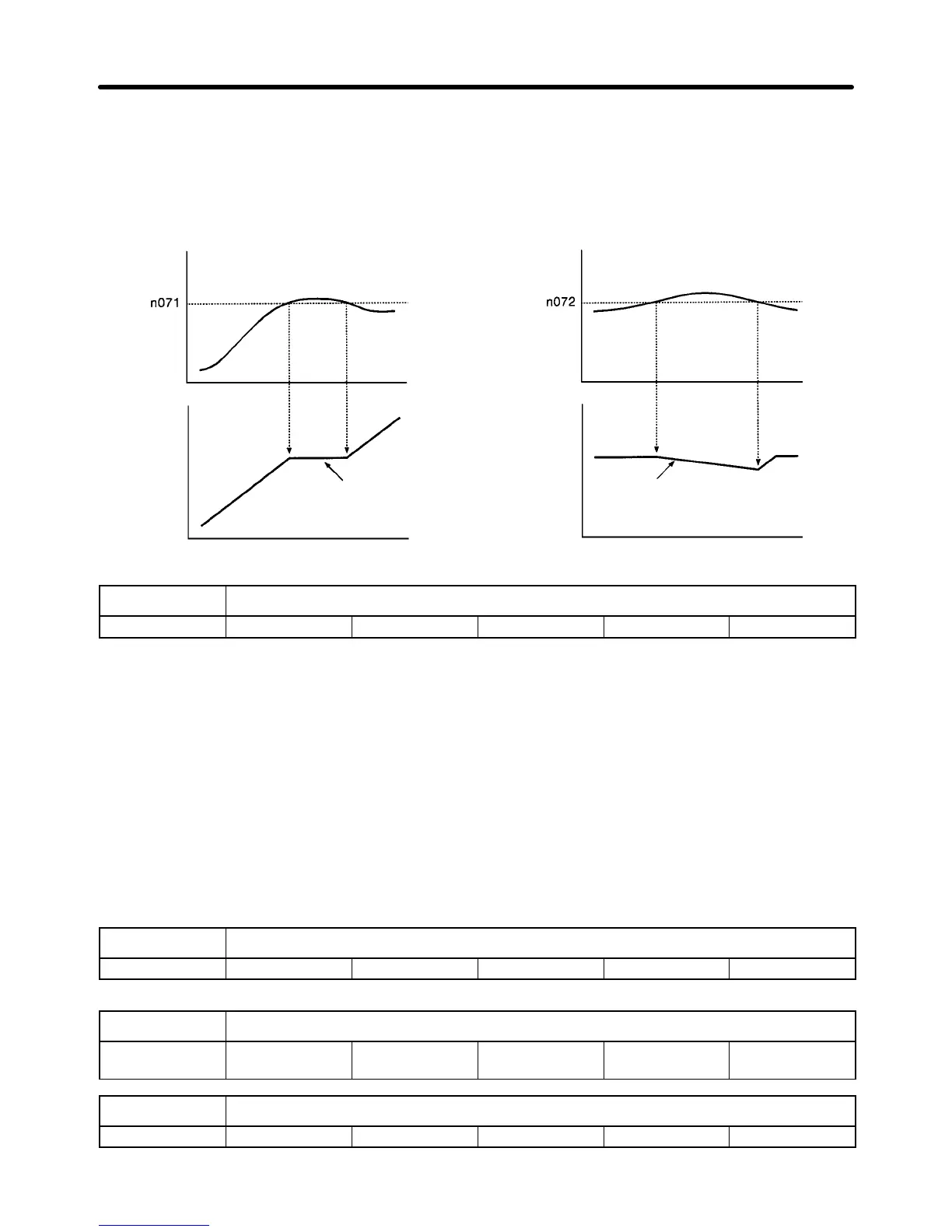

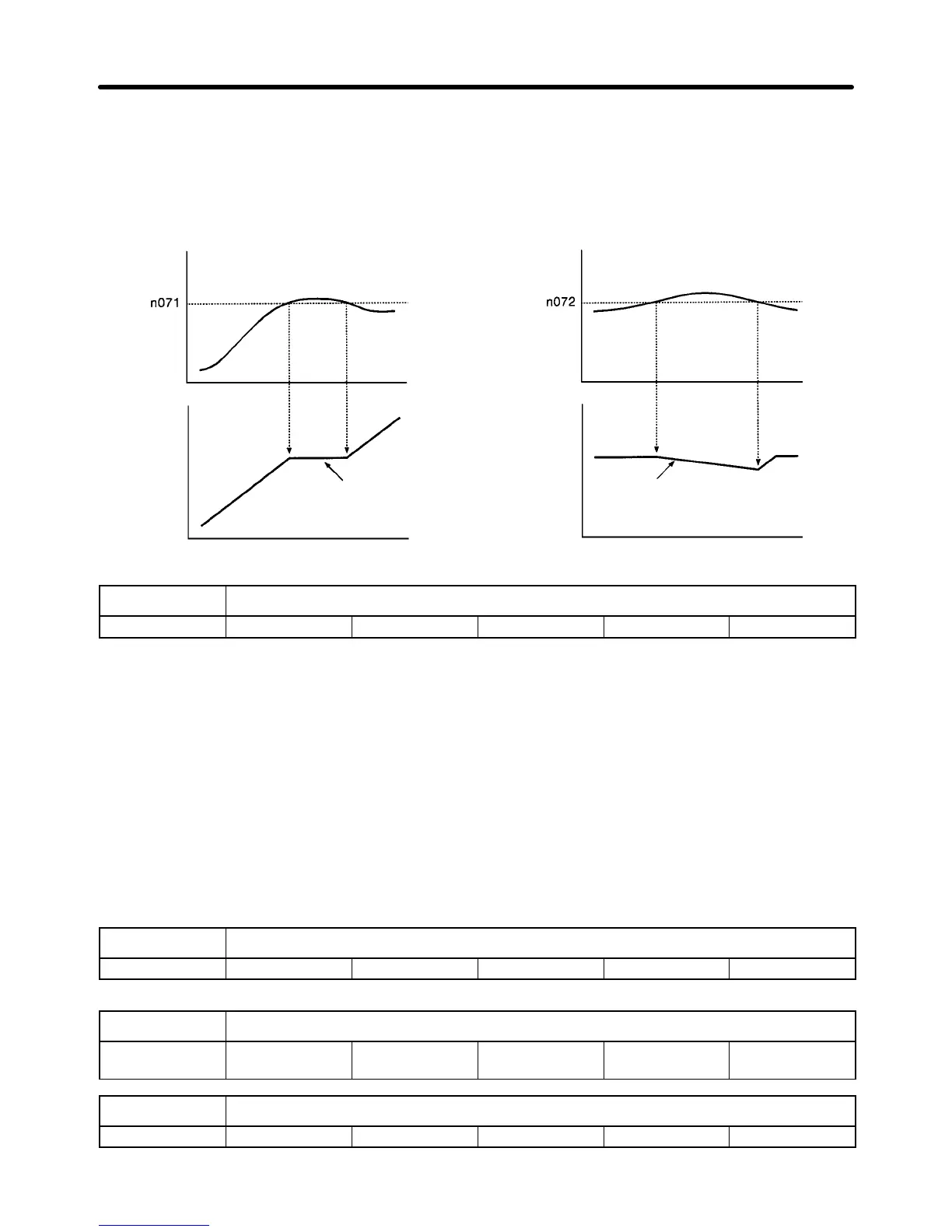

• The

parameters n071 and n072 are used to lower the output frequency to levels to enable the Inverter

to continue operating the motor without stalling.

• Set

with n071 and n072 current levels in 1% units based on the rated output current as 100% to enable

the acceleration and operation stall prevention functions to work.

Acceleration Stall Prevention Operation Stall Prevention

Operation

Stall

Prevention

Time

Time

The output frequency is controlled to a

level to enable the Inverter to continue

operating the motor without stalling.

Output

frequency

Time

Time

The output frequency is controlled to a

level to enable the Inverter to continue

operating the motor without stalling.

Output

frequency

Operation

Stall

Prevention

n073 Frequency Detection Level

Setting range 0.0 to 400.0 Unit Hz Default setting 0.0

• The parameter n073 is used to detect the output frequency.

• The

Inverter will output a signal as a multi-function contact output while the output frequency is higher

than, lower than, or the same as the frequency set with n073.

• Set n040 and n041 (i.e., multi-function contact output selection):

To

3 to permit the Inverter to output a

signal while the output frequency is the same as the frequency

set with n073.

To

4 to permit the Inverter to output a signal while the output frequency is the same as or lower than

the frequency set with n073.

To

5

to permit the Inverter to output a signal while the output frequency is the same as or higher than

the frequency set with n073. Refer to

page 3-76

.

n074 Overtorque Detection Function Selection

Setting range 0 to 4 Unit --- Default setting 0

n075 Overtorque Detection Level

Setting range 30 to 200 Unit % (Rated output

current ratio)

Default setting 160

n076 Overtorque Detection Time

Setting range 0.1 to 10.0 Unit s Default setting 0.1

Preparing for Operation Chapter 3

Loading...

Loading...