3-33

H PID Control Function

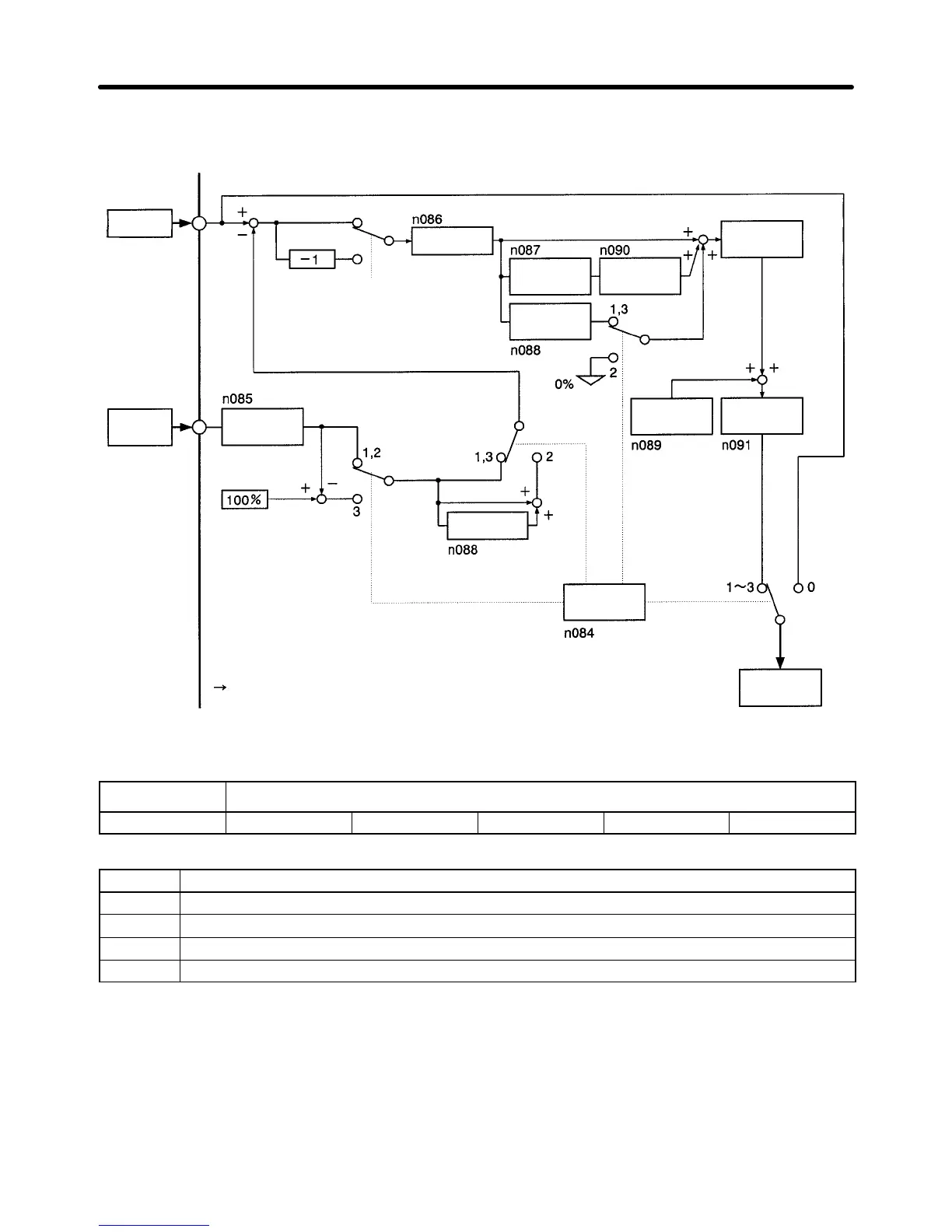

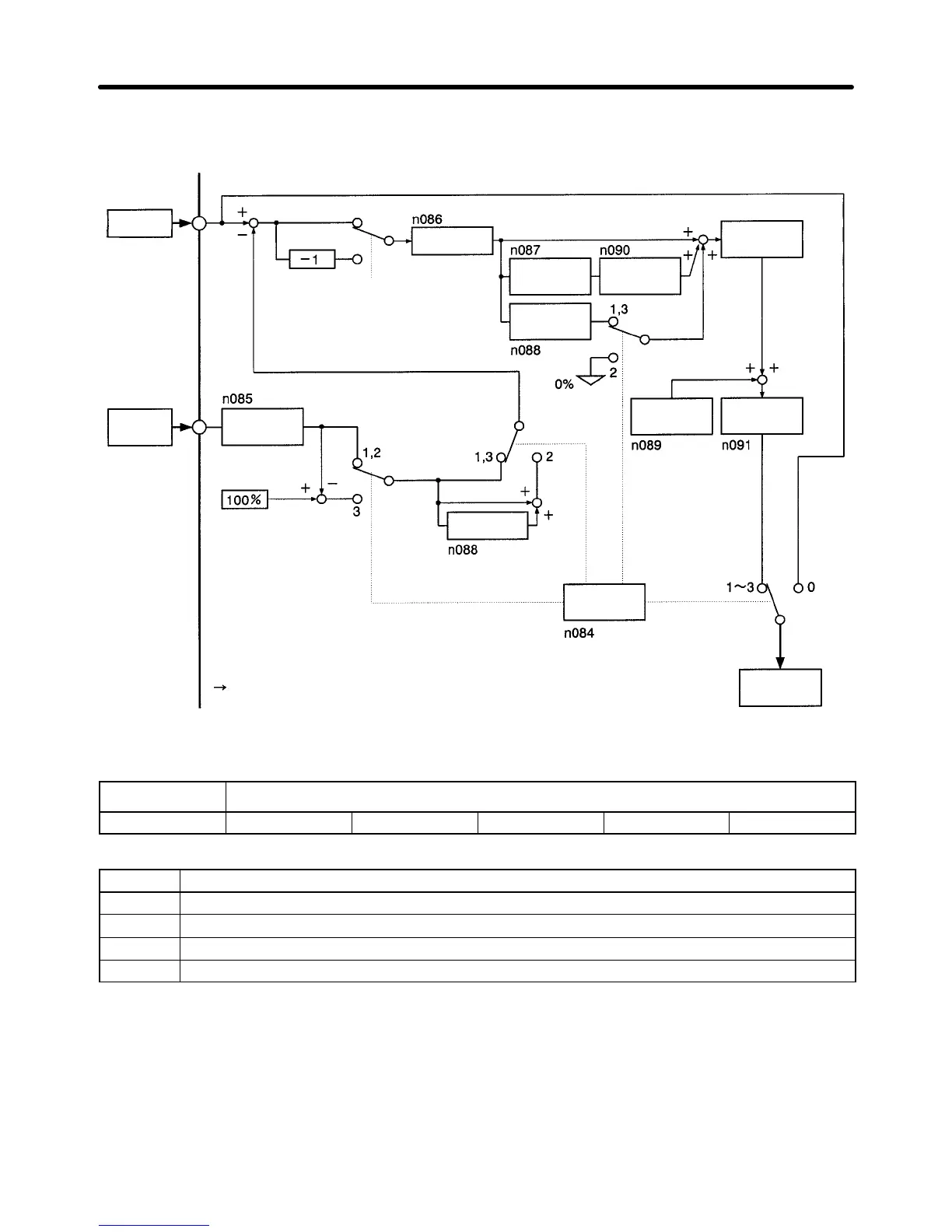

Refer to the following block diagram for the PID control performed by the Inverter.

Set

point

Feedback

FV

terminal

FI terminal

Feedback

ad

-

justment gain

100%:

Feedback value

corresponding to the

maximum frequency

(N012)

Inside the Inverter

Multi-function

input/PID input selection

Proportional

gain

1/Integral

time

Derivative

time

Upper

limit

of integral (I)

Internal

limit

±109%

PID of

fset

adjustment

PID

primary

delay

time constant

PID

control

selection

Inverter

fre

-

quency refer

-

ence

Derivative

time

H PID Control Settings

n084

PID Control Function Selection

Setting range 0, 1, and 2 Unit --- Default setting 0

Set Values

Set value Description

0 No PID control.

1 PID control with deviation derivative control.

2 PID control with feedback derivative control.

3 PID control with negative feedback characteristic control.

Note 1. Set n084 to 1, 2, or 3 to permit the Inverter to perform PID control.

Note 2. Usually set n084 to 2 to change set points.

Note 3. Set

n084 to

3 to perform PID control using the negative characteristic of the characteristic of

the

feedback value input from the sensor

. Using the negative characteristic means that [100%

–

feedback value] is used as the PID feedback value. This is ef

fective for negative characteris

-

tic control (control where the feedback value drops when the Inverter’s output frequency

rises).

Preparing for Operation Chapter 3

Loading...

Loading...