3-31

3-5-2 PID Control

PID

(proportional, integral, and derivative) control is a method to control a

mechanical

system

by making the feedback values obtained from the mechanical system agree with

the set point that has been preset.

This method makes it possible to control a mechanical system that has dead time.

The

Inverter is not suitable for PID

control that requires a response time of 50 ms or less.

Refer

to the following for examples of PID control that can be performed

by the Inverter

as

well as the operation of PID control in detail and the settings and adjustments of the

parameters.

H Examples of PID Control

Refer to the following for examples of PID control that can be performed by the Inverter.

Application Control Required sensor

Speed control The Inverter uses the feedback of speed data of the

mechanical system and makes the operation speed of

the mechanical system agree with the set point.

The Inverter controls the mechanical system in

synchronization with another mechanical system that

inputs its speed data as the set point to the Inverter.

Tachometric generator

Pressure control The Inverter performs constant pressure control with the

feedback of pressure data.

Pressure sensor

Flow control The Inverter performs flow control with the feedback of

flow data.

Flow sensor

Temperature control The Inverter performs temperature control using fans with

the feedback of temperature data.

Thermocouple

Thermistor

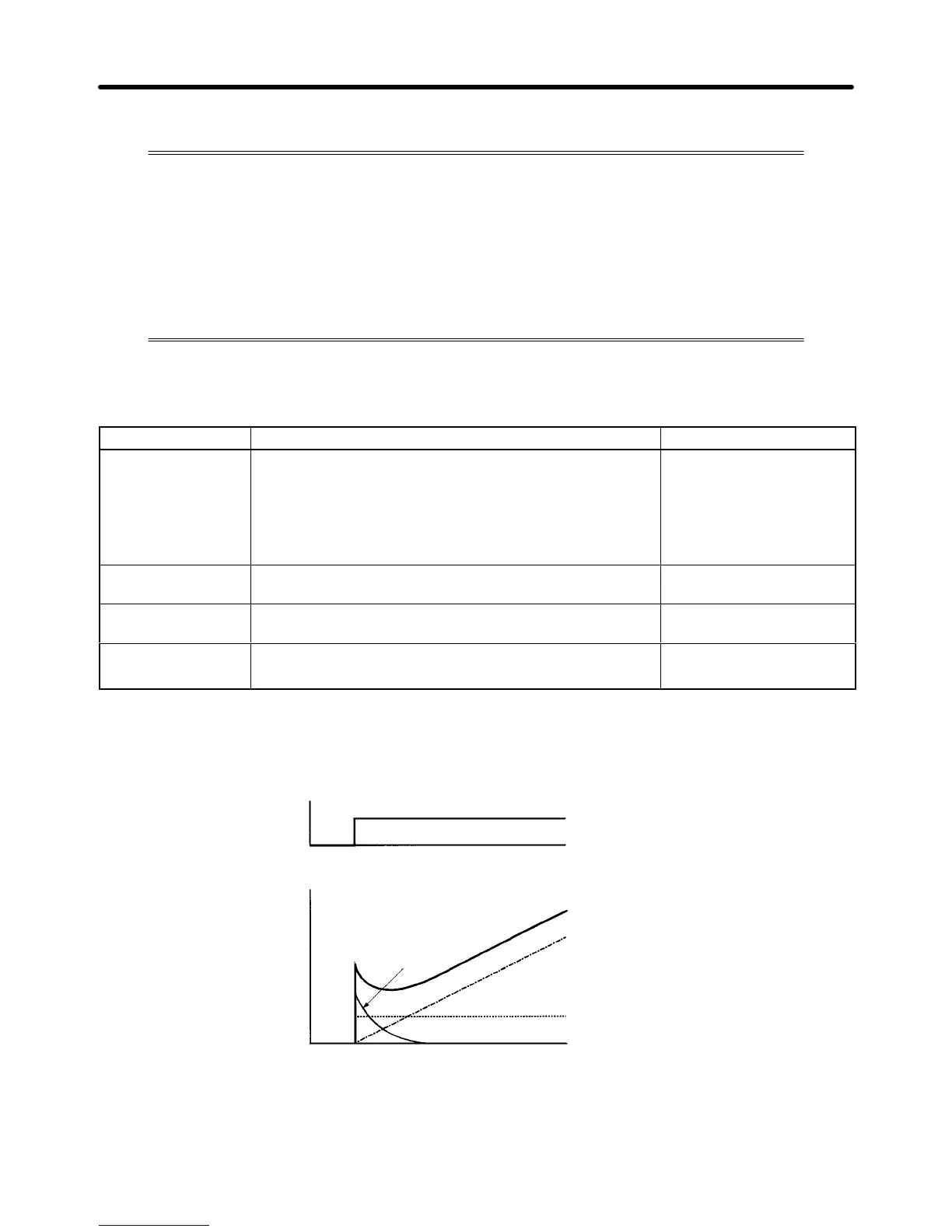

H PID Control Operation

The

following graph shows control output (output frequency) changes with a constant

deviation (i.e., the

difference between the set point and feedback is constant).

Deviation

Time

Control

output

Derivative

control

PID control

Integral control

Proportional control

Time

D Proportional Control

Control

output in proportion to the deviation is obtained through proportional control. Proportional

control alone cannot make the deviation zero.

Preparing for Operation Chapter 3

Loading...

Loading...