3-37

Note Measure the response waveform so that the timing of the step input will be known.

2. Calculation of PID Parameters

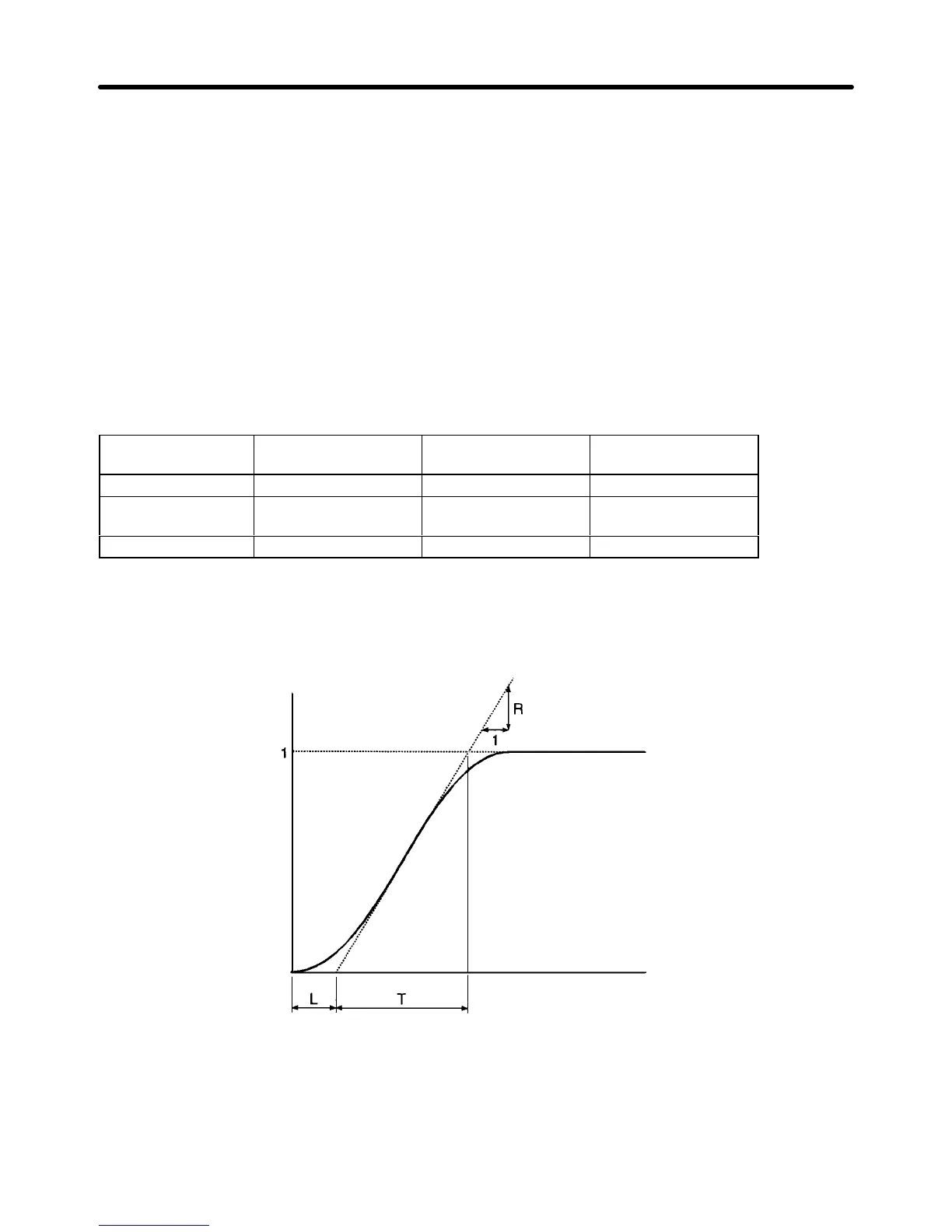

S Draw a tangent line contacting with the steepest inclining point of the response waveform.

S Measurement of R

Measure the gradient of the tangent line provided that the set point is 1.

S Measurement of L

Measure

the required time (seconds) between the origin and the point of intersection of the tan

-

gent line and time axis.

S Measurement of T

Measure

the required

time (seconds) between the point of intersection of the tangent line and time

axis and the point of intersection of the tangent line and set point line.

S PID Parameters

The following can be calculated from the R, L, and T values as “rules of thumb.”

Control Proportional gain (P)

(n086)

Integral time (I)

(n087)

Derivative time (D)

(n088)

Proportional control 0.3/RL --- ---

Proportional/Integral

control

0.35/RL 1.2T ---

PID control 0.6/RL T 0.5L

Note 1. Obtain

PID parameter values from the above

method, set the PID parameters, and tune in the

PID parameter values exactly.

Note 2. PID

parameter values

obtained from the above method may not be optimum values if the fric

-

tion factor of the mechanical system is large.

Response

Time

Set

point

D Manual Adjustments

Take

the following steps

to adjust the PID parameter values of the Inverter performing PID control by

measuring the response waveform.

1. Set n084 to 2 or 1 so that the Inverter will perform PID control.

Preparing for Operation Chapter 3

Loading...

Loading...