XtraDrive User Manual Chapter 5: Parameter Settings and Functions

5-73

5.6.1. External Regenerative Resistor

When installing an external regenerative resistor, a parameter setting

must be changed as shown below.

Parameter Signal Setting (x 10W)

Description

Pn600

Regenerative

Resistor Capacity

Setting Range: 0 to maximum

Default Setting: 0

Speed/Torque Control,

Position Control

The default setting of “0” in the above table is the set value when the

servo amplifier’s built-in resistor is used or when a servo amplifier

without a built-in resistor is used.

When installing an external regenerative resistor, set the regenerative

resistor’s capacity (W).

Example:

When the external regenerative resistor’s actual consumable capacity is 100W, set the parameter to

“10” (10 x 10W = 100W)

Note: 1. In general, when resistors for power are used at the rated load ratio, the resistor temperature increases

to between 200°C and 300°C. The resistors must be used at or below the rated values.

Check with the manufacturer for the resistor’s load characteristics. Use resistors at no more than 20% of

the rated load ratio with natural convection cooling, and no more than 50% of the rated load ratio with

forced air-cooling. Parameter Pn600 must be set for the derated resistor.

2. Use of resistors with thermal switches is recommended as a safety precaution.

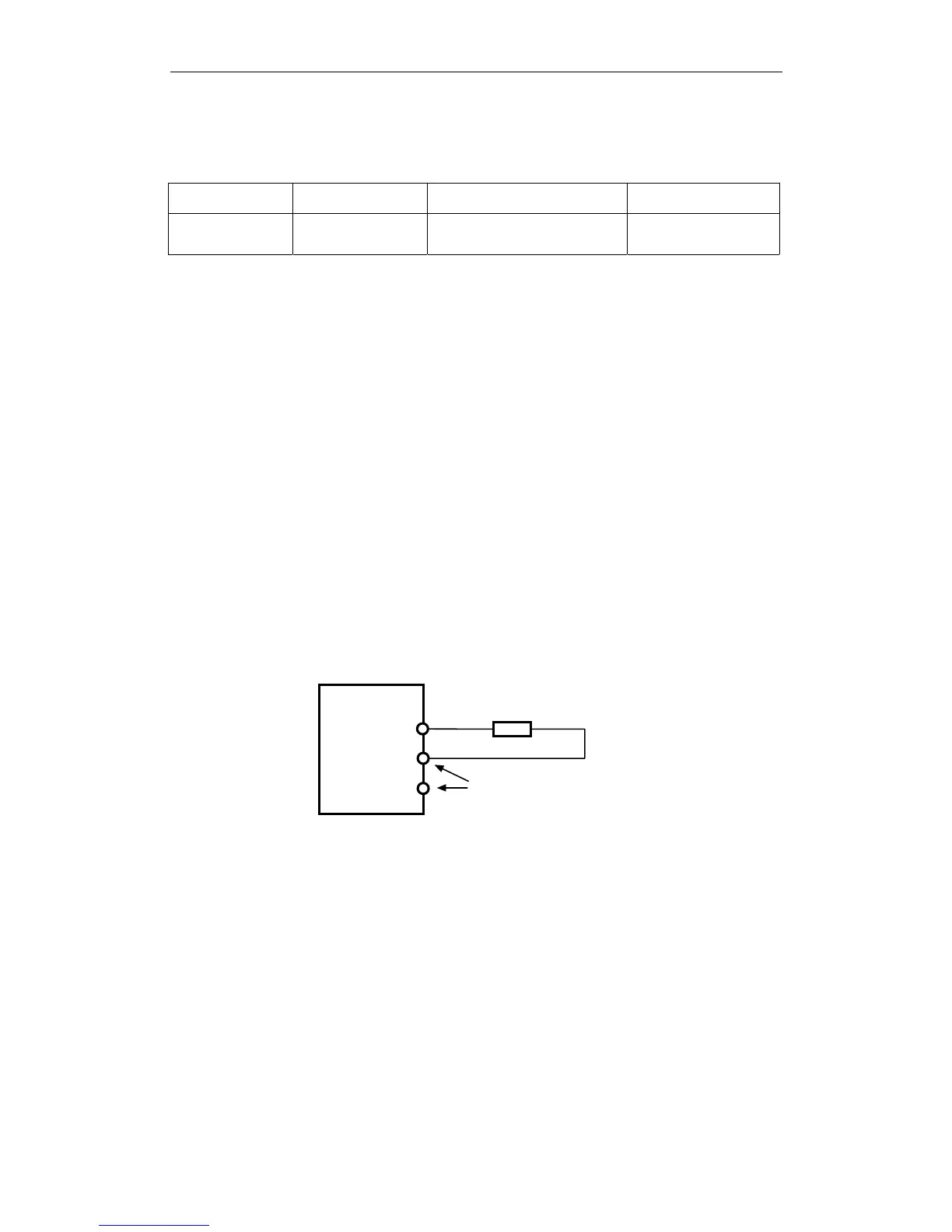

Connecting Regenerative Resistors

The method for connecting regenerative resistors is as follows.

Disconnect the wire between the servo amplifier’s B2 and B3 terminals

and connect an external regenerative resistor between the B1 and B2

terminals.

Regenerative resistor

B1

B2

Xt r a Dri ve

*The user must provide the regenerative resistor.

B3

Be sure to take out the lead wire

between the B2 and B3 terminals.

Loading...

Loading...