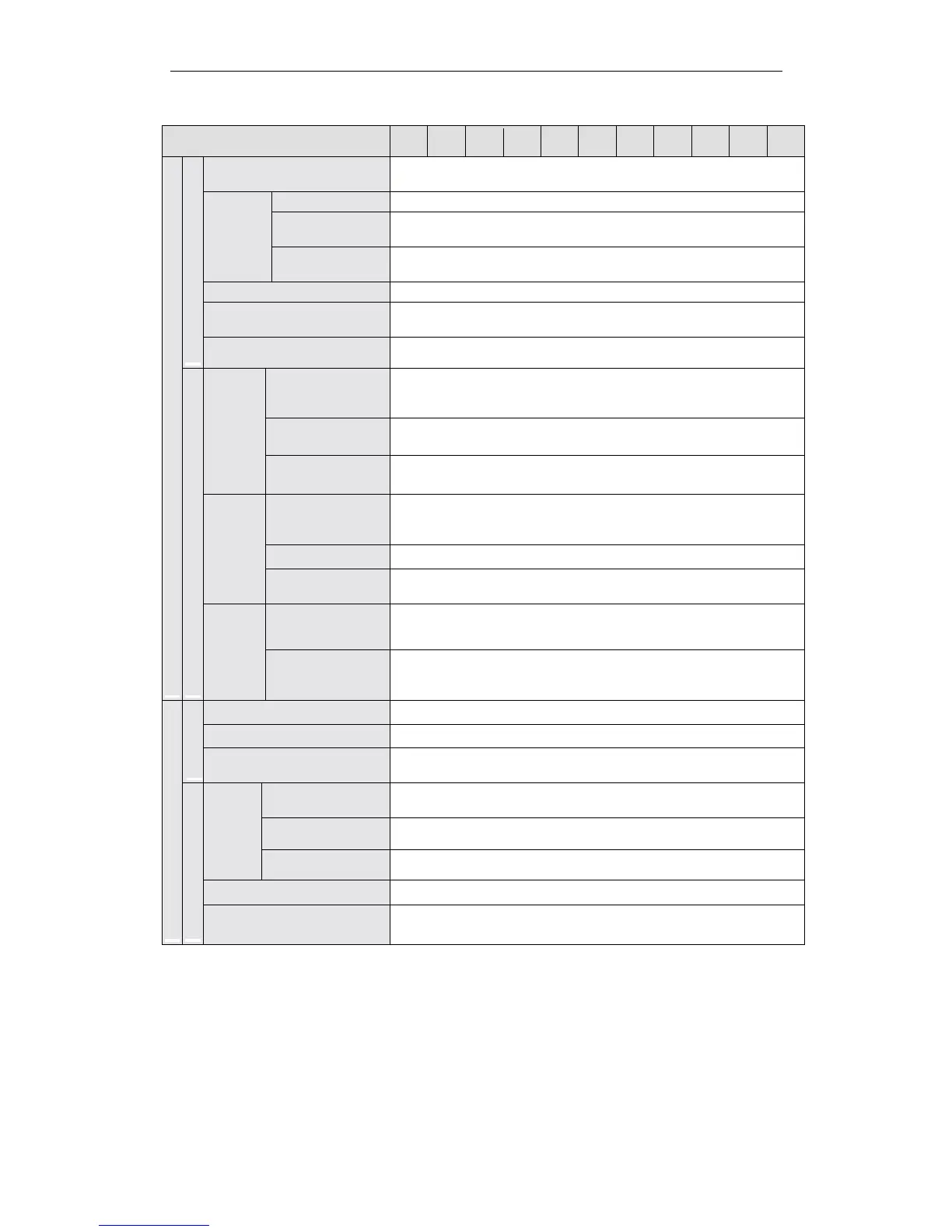

XtraDrive User Manual Chapter 8 : Ratings, Specifications and Dimensional Drawings

8-4

XtraDrive Ratings and Specifications (continued)

XtraDrive Model

XD-

P3 P5 01 02 04 05 08 10 15 20 30

Speed Control Range

1:5000 (The lowest speed of the speed control range is the point just

before the motor stops under full-load condition.)

Load Regulation 0 to 100% load: 0.01% maximum (at rated speed)

Voltage

Regulation

Rated Voltage ±10%: 0% (at rated speed)

Speed

Regulation *

Temperature

Regulation

25 ± 25°C: ±0.1% max. (at rated speed)

Frequency Characteristics 400Hz (at J

L

= J

M

)

Torque Control Tolerance

(Repeatability)

±2%

Performance

Soft Start Time Setting 0 to 10s (Can be set individually for acceleration and deceleration)

Reference

Voltage**

±6V

DC

(Variable setting range: ±2 to ±10V

DC

) at rated torque (positive

torque reference with positive reference), input voltage: ±12V

(maximum).

Input Impedance About 14kΩ

Speed Reference

Input

Circuit Time

Constant

—

Reference

Voltage**

±3V

DC

(Variable setting range: ±1 to ±10V

DC

) at rated torque (positive

torque reference with positive reference), input voltage: ±12V

(maximum)

Input Impedance About 14kΩ

Torque

Reference

Input

Circuit Time

Constant

About 47µs

Rotation Direction

Selection

With P control signal

Speed and Torque Control Modes

Input Signals

Contact

Speed

Reference

Speed Selection

With forward/reverse current limit signal (speed 1 to 3 selection),

servomotor stops or another control method is used when both are

OFF.

Bias Setting 0 to 450rpm (setting resolution: 1rpm)

Feed Forward Compensation 0 to 100% (setting resolution: 1%)

Performa

n

Positioning Completed Width

Setting

0 to 250 reference units (setting resolution: 1 reference unit)

Type

Sign + pulse train, 90° phase difference 2-phase pulse (A phase + B

phase), or CCW + CW pulse train

Form Line driver (+5V level), open collector (+5V or +12V level)

Reference

Pulse

Frequency 500/200kpps maximum (line driver/open collector).

Control Signal Clear Signal (input pulse form identical to reference pulse)

Position Control Mode

Input Signals

Built-in Open-Collector Power

Supply***

+12V (1kΩbuilt-in resistor)

* Speed regulation is defined as follows:

The motor speed may change due to voltage variations or amplifier drift and changes in processing resistance due

to temperature variation. The ratio of speed changes to the rated speed represents speed regulation due to voltage

and temperature variations.

** Forward is clockwise viewed from the non-load side of the servomotor, (counterclockwise viewed from the

load and shaft end).

***The built-in open collector power supply is not electrically isolated from the control circuit in the servo amplifier.

Loading...

Loading...