XtraDrive User Manual Chapter 6: Servo Adjustment

6-10

6.2.10. Gain Setting Reference Values

This section describes servo gain reference values.

Refer to the following for optimal gain adjustments according to the

rigidity of the mechanical system. Refer to these values and use the

previously mentioned methods to make gain adjustments. These values

are for reference only and do not mean that the mechanical system has

good response characteristics or is free from oscillation in the specified

ranges.

Observe the response by monitoring the response waveform and make

the optimal gain adjustments. If the rigidity of the machinery is high,

gain increments exceeding the described ranges are possible.

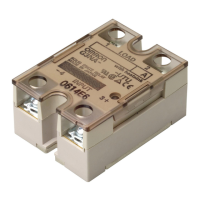

Machines with High Rigidity

These machines are directly connected to ball screws.

Examples: Chip mounting machine, bonding machine, and high-

precision machine tool

Speed Loop Gain (Pn100)

Speed Loop Integral Time Constant

(Pn101)

50 to 70Hz 5 to 20ms

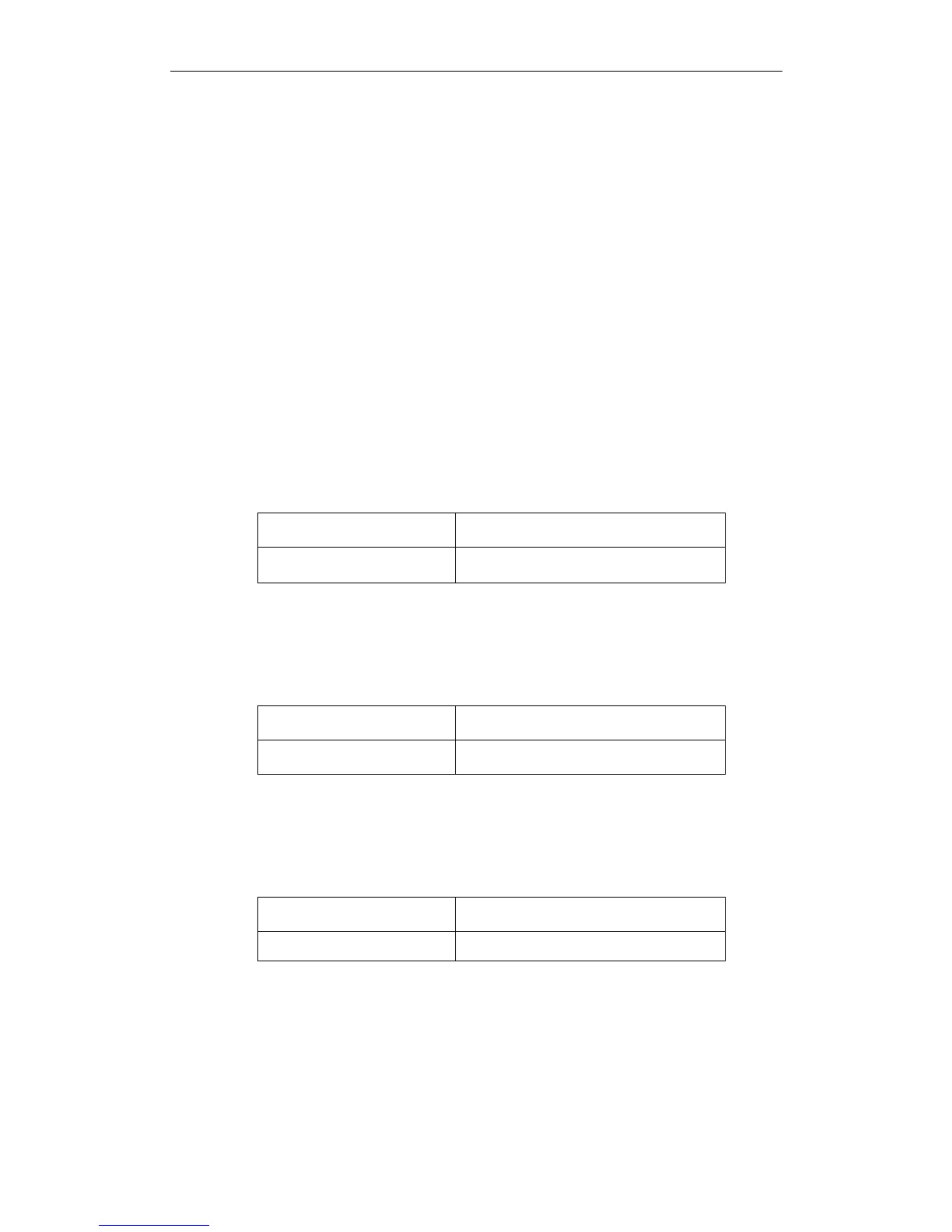

Machines with Medium Rigidity

Machines driven by ball screws through speed reducers or long-length

machines directly driven by screws.

Examples: General machine tool, transverse robot, and conveyor

Speed Loop Gain (Pn100)

Speed Loop Integral Time Constant

(Pn101)

30 to 50Hz 10 to 40ms

Machines with Low Rigidity

These machines are driven by timing belts, chains or machines with

harmonic gear reducers.

Examples: Conveyor and articulated robot

Speed Loop Gain (Pn100)

Speed Loop Integral Time Constant

(Pn101)

10 to 20Hz 50 to 120ms

Loading...

Loading...