XtraDrive User Manual Chapter 5: Parameter Settings and Functions

5-21

Output Phase Form

t

t

Reverse

rotation

Forward

rotation

90

°

90

°

Input SEN CN1-4 SEN Signal Input Speed/Torque Control

Input /SEN CN1-2 Signal Ground Speed/Torque Control

Output PSO CN1-48 Encoder Output Phase S Speed/Torque Control, Position Control

Output /PSO CN1-49 Encoder Output Phase /S Speed/Torque Control, Position Control

Input BAT (+) CN1-21 Battery (+) Speed/Torque Control, Position Control

Input /BAT (-) CN1-22 Battery (-) Speed/Torque Control, Position Control

Use SEN to BAT (-) signals for absolute encoders. See 5.7 Absolute Encoders for

more details.

Output SG CN1-1 Signal ground Speed/Torque Control, Position Control

SG: Connect to 0V on the host controller.

IMPORTANT

•

When using the servo amplifier phase C pulse signal to return to the machine origin,

always turn the servomotor at least twice before starting the original return operation.

If the configuration of the mechanical system prevents turning the servomotor before the

origin return operation, then perform the origin return operation at a servomotor speed of

600rpm or below. The phase C pulse signal may not be correctly applied if the servomotor

turns faster than 600rpm.

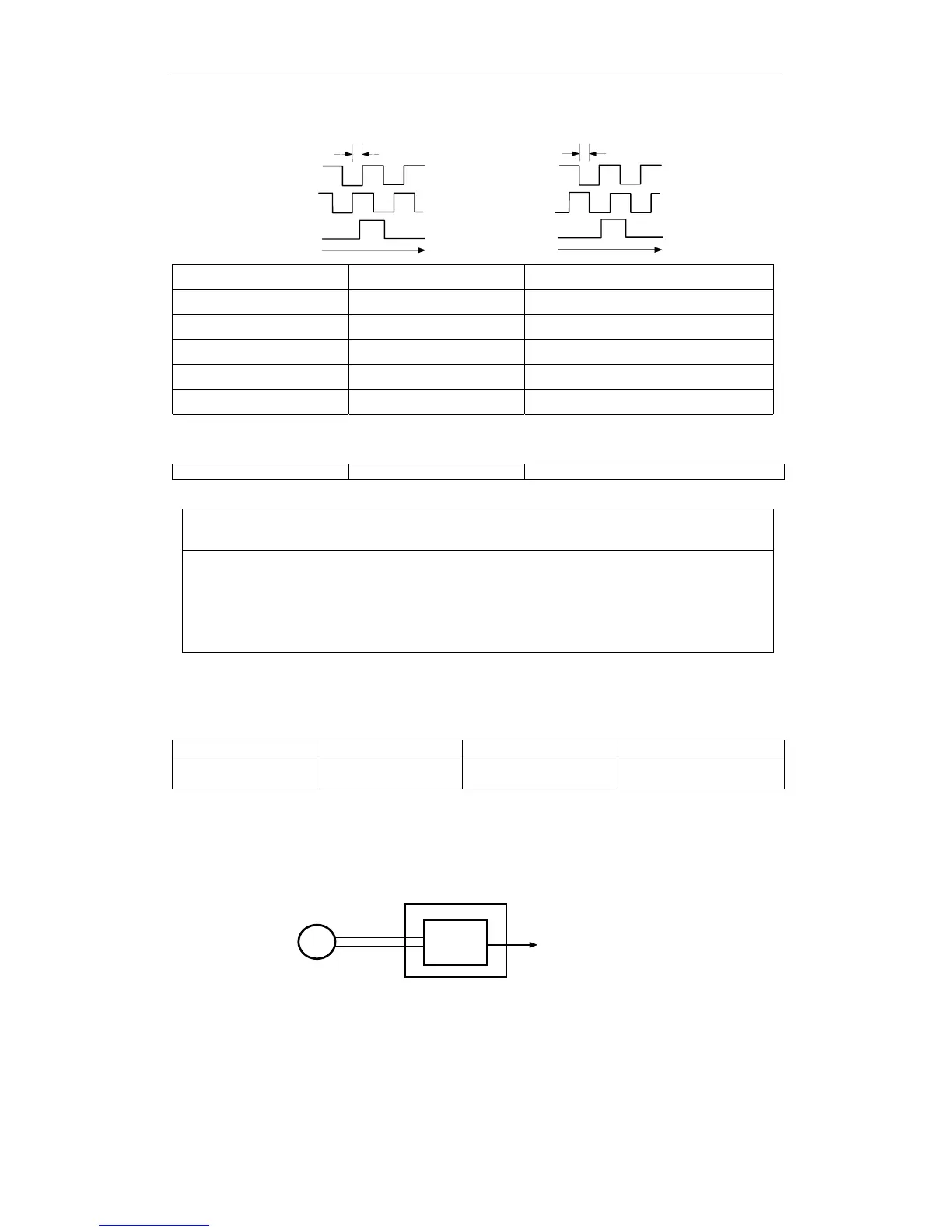

Pulse Divider Setting

Set the pulse dividing ratio in the following parameter:

Parameter Signal Setting (PPR) Control Mode

Pn201 PG Divider

Range: 0 to 65535

Default Setting: 2048

Speed/Torque Control,

Position Control

Serial encoder

Set the number of pulses for PG output signals (PAO, /PAO, PBO,

/PBO).

Xt r aD ri ve

Frequency

division

Encoder

PG

Phase A

Phase B

Serial

data

Output

Output terminals: PAO (CN1-33)

/PAO (CN1-34)

PBO (CN1-35)

/PBO (CN1-36)

Pulses from the servomotor encoder (PG) are divided by the preset

number before being output.

The number of output pulses per revolution is set by this parameter. Set

the value using the reference units of the equipment or the controller

used.

The setting range varies with the encoder used.

Loading...

Loading...