XtraDrive User Manual Chapter 5: Parameter Settings and Functions

5-26

2. Determine the reference unit used.

A reference unit is the minimum position data unit used to move a

load (minimum unit of reference from the host controller).

Reference unit: 0.001 mm

Determine the reference unit according to

equipment specifications and positioning accuracy.

To move a table in 0.001 mm units

Examples (in mm):

• Reference unit can be 0.1in or 0.01in or 0.01mm or 0.001mm,

etc. A reference unit of one pulse moves the load by one

reference unit.

• When the reference unit is 1µm

If a reference of 50000 units is input, the load moves 50mm

(1.97in) (50000 ⋅ 0.001mm = 50mm).

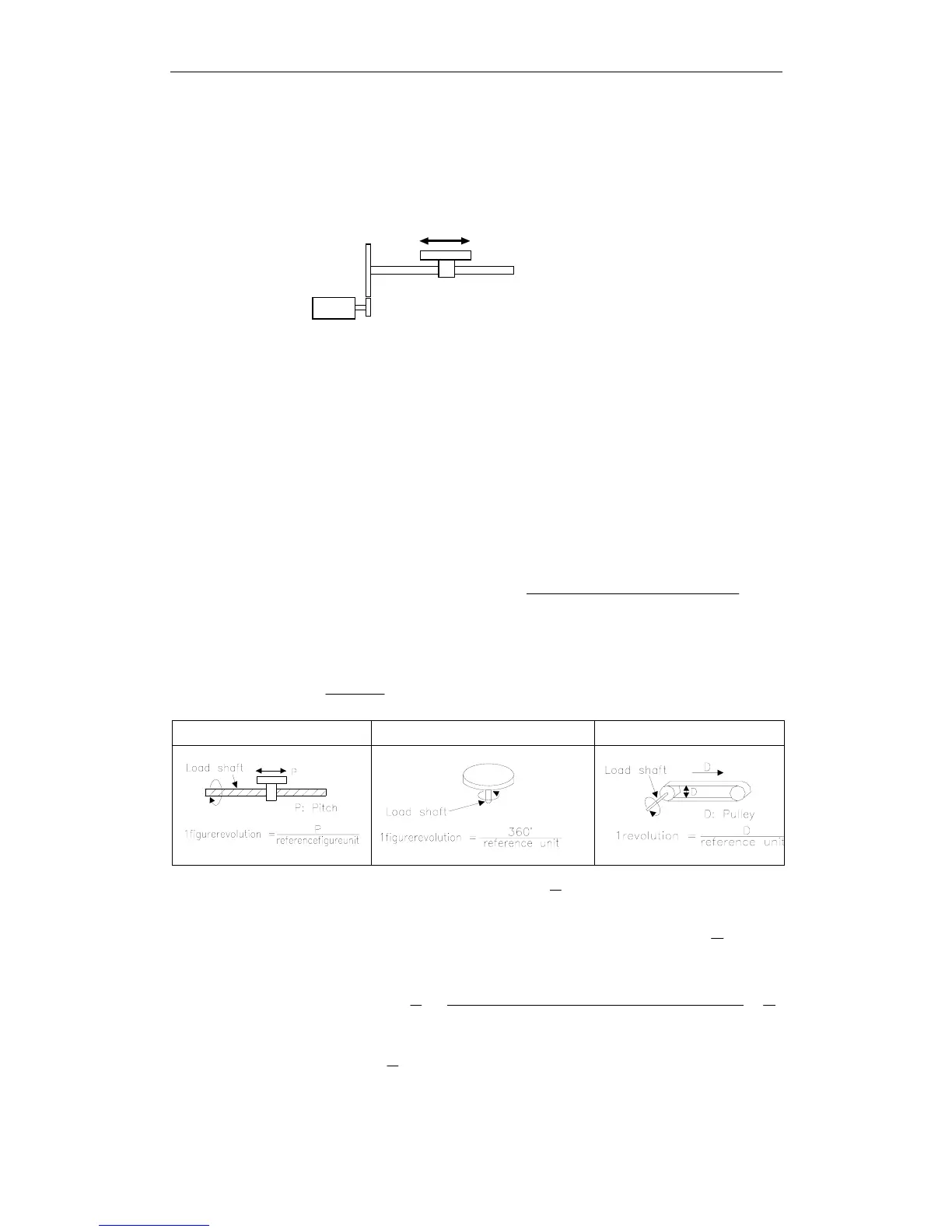

3. Determine the travel distance per load shaft revolution in reference

units.

Travel distance per load shaft revolution =

UnitReference

revolutionshaft loadper distance Travel

• When the ball screw pitch is 0.20in (5mm) and the reference unit

is 0.00004in (0.001mm),

00004.0

20.0

= 5000 (reference units)

Ball Screw Disc Table Belt and Pulley

π

π

4. Electronic gear ratio is given as:

A

B

If the gear ratio of the motor and the load shaft is given as:

n

m

where

m is the rotation of the motor and n is the rotation of the load shaft,

Electronic gear ratio

A

B

=

unit) (reference revolutionshaft loadper distance Travel

4x pulsesencoder ofNumber

x

n

m

Note: Make sure the electronic gear ratio satisfies the following condition:

0.01 ≤ Electronic gear ratio

A

B

≤ 100

The servo amplifier will not work properly if the electronic gear ratio exceeds this range. In that case,

modify either the load configuration or the reference unit.

Loading...

Loading...