XtraDrive User Manual Chapter 5: Parameter Settings and Functions

5-27

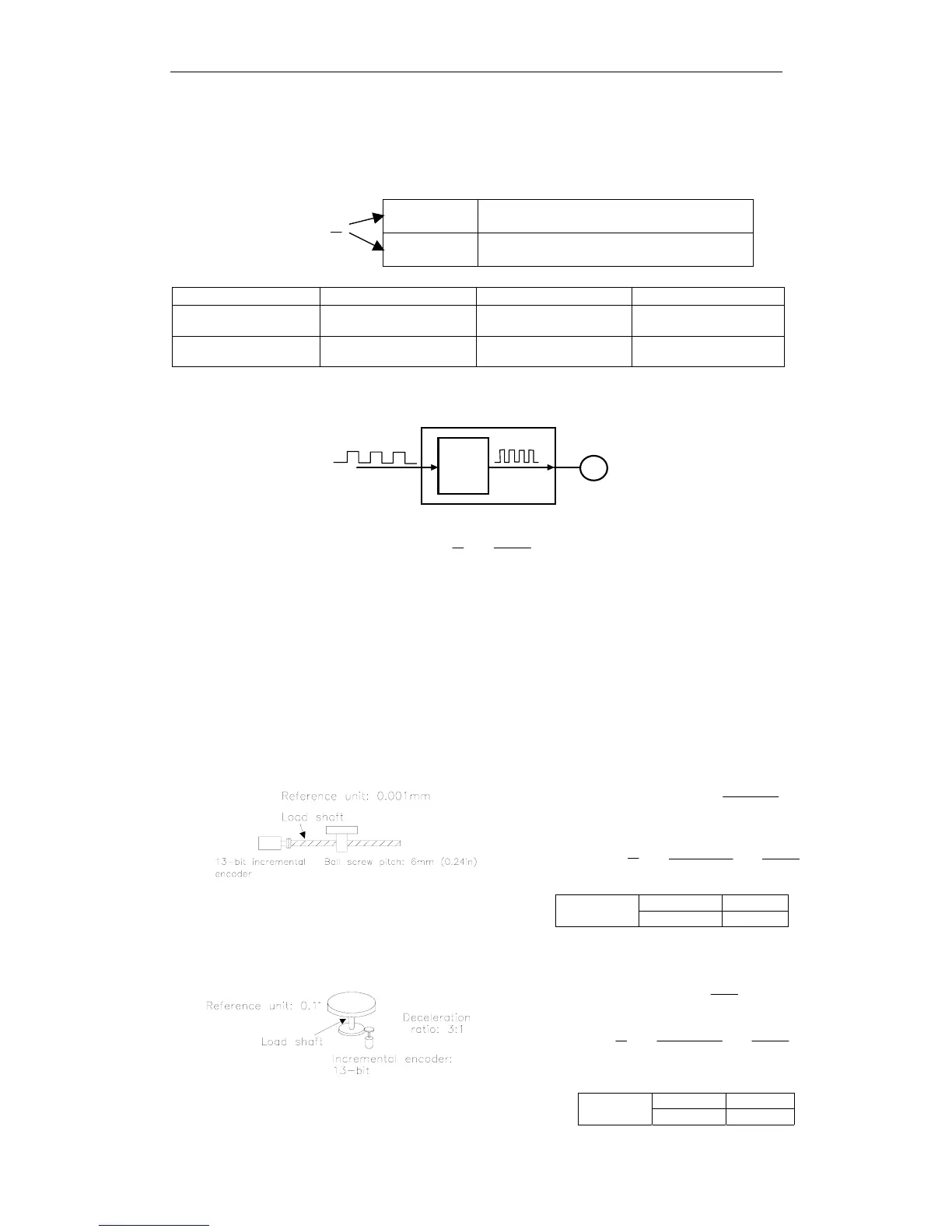

5. Set the parameters.

Reduce the electronic gear ratio to lower terms so that both A and B

are integers smaller than 65535, then set A and B in the respective

parameters:

Pn202 Electronic Gear Ratio (Numerator)

A

B

Pn203 Electronic Gear Ratio (Denominator)

Parameter Signal Setting Control Mode

Pn202

Electronic Gear Ratio

(Numerator)

Range: 1 to 65535

Default Setting: 4

Position Control

Pn203

Electronic Gear Ratio

(Denominator)

Range: 1 to 65535

Default Setting: 1

Position Control

Set the electronic gear ratio according to equipment specifications.

M

Electronic

gear

B

_

A

Motor

Xtra D ri ve

Reference

input pulse

Electronic Gear Ratio =

A

B

=

203Pn

202Pn

• B = [(Number of encoder pulses) × 4] × [motor speed]

• A = [Reference units (travel distance per load shaft revolution)] ×

[load shaft revolution speed]

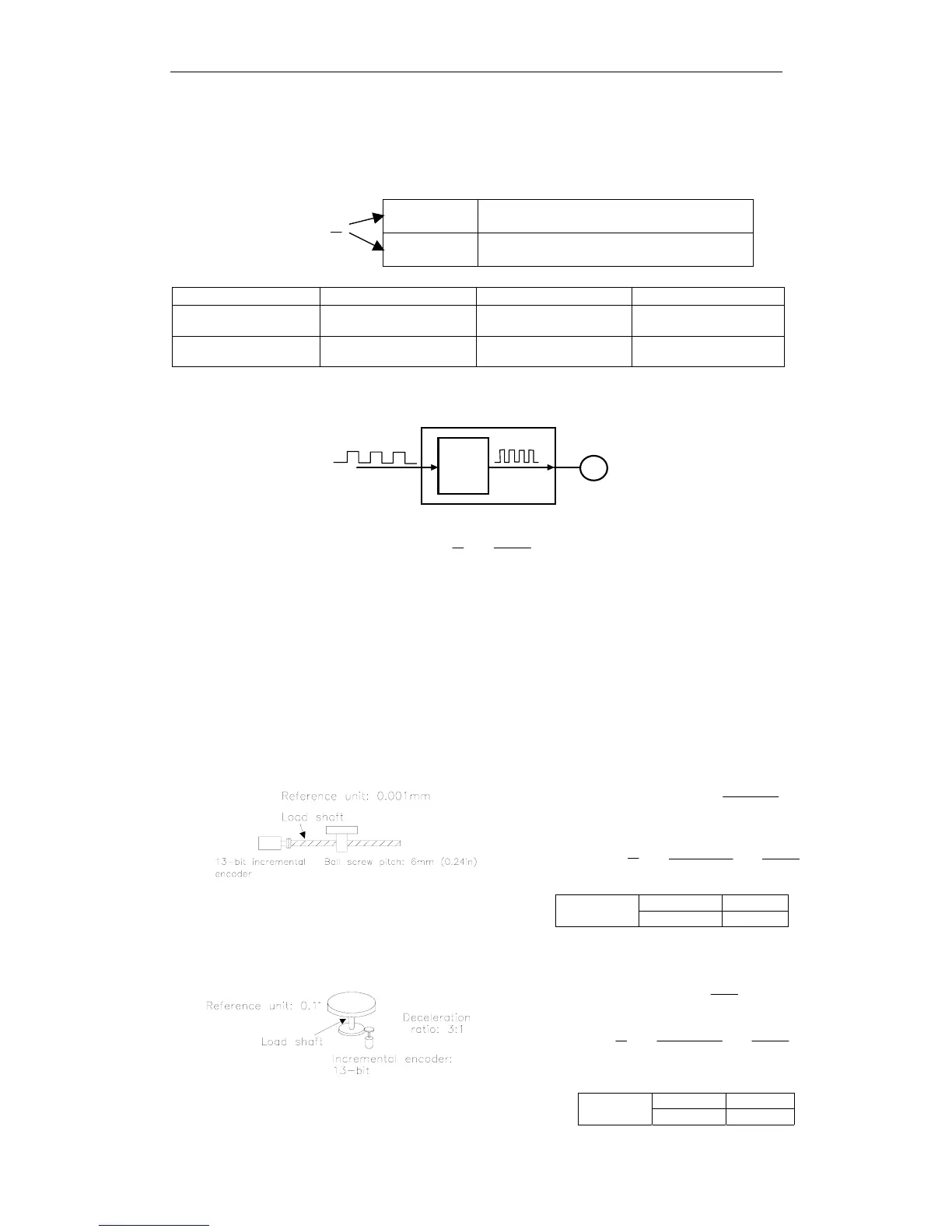

Electronic Gear Setting Examples

The following examples show electronic gear settings for different load

mechanisms.

Ball Screws

Travel distance per load shaft revolution =

in00004.0

in24.0

=

6000

Electronic gear ratio

=

A

B

=

6000

1x 4x 2048

=

203Pn

202Pn

Pn202 8192

Preset

Values

Pn203 6000

Circular Tables

Travel distance per load shaft revolution =

°

°

1.0

360

= 3600

Electronic gear ratio

=

A

B

=

3600

3x 4x 2048

=

203Pn

202Pn

Pn202 24576

Preset

Values

Pn203 3600

Loading...

Loading...