U.6.20

SEL-421 Relay User’s Guide Date Code 20090715

Testing and Troubleshooting

Test Methods

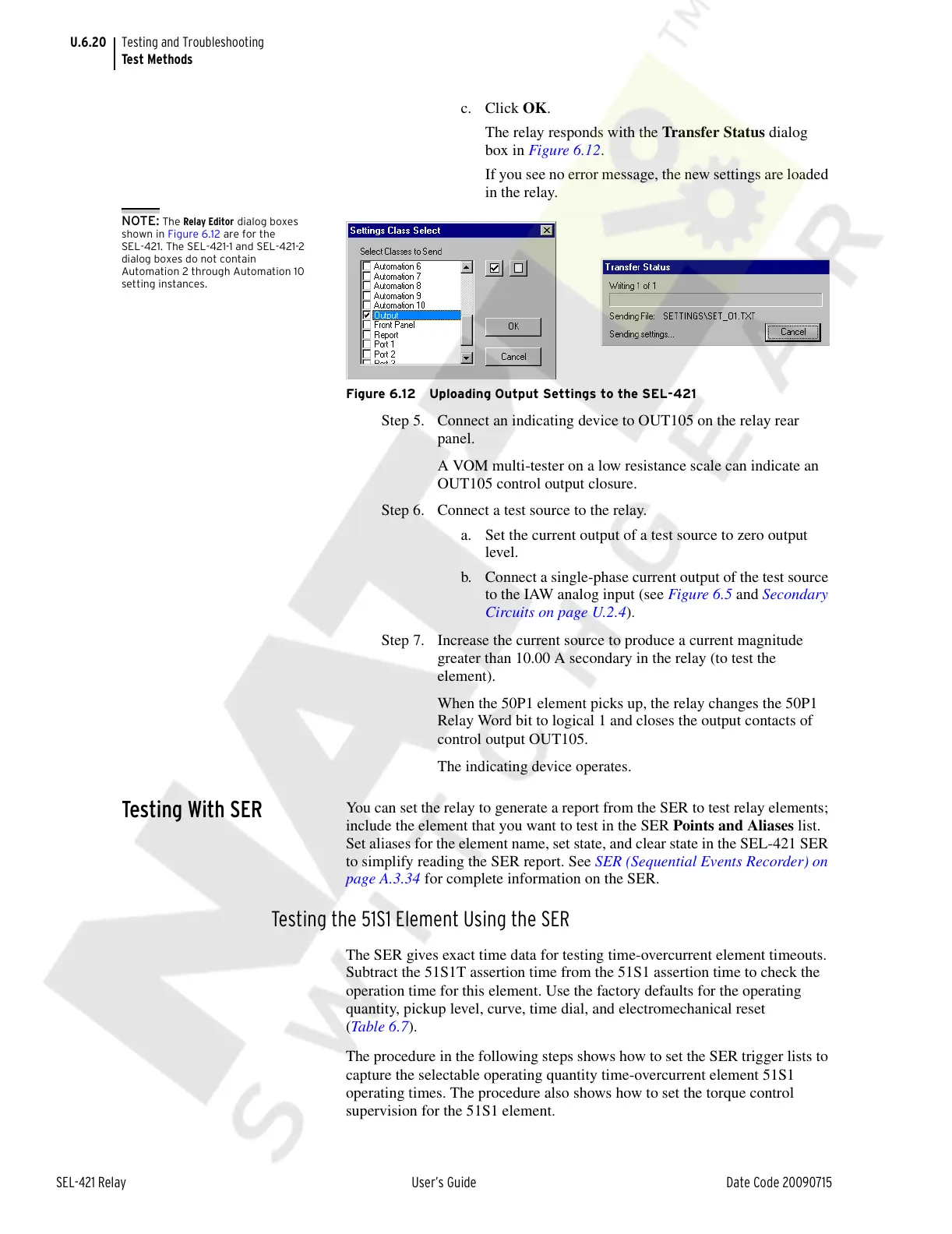

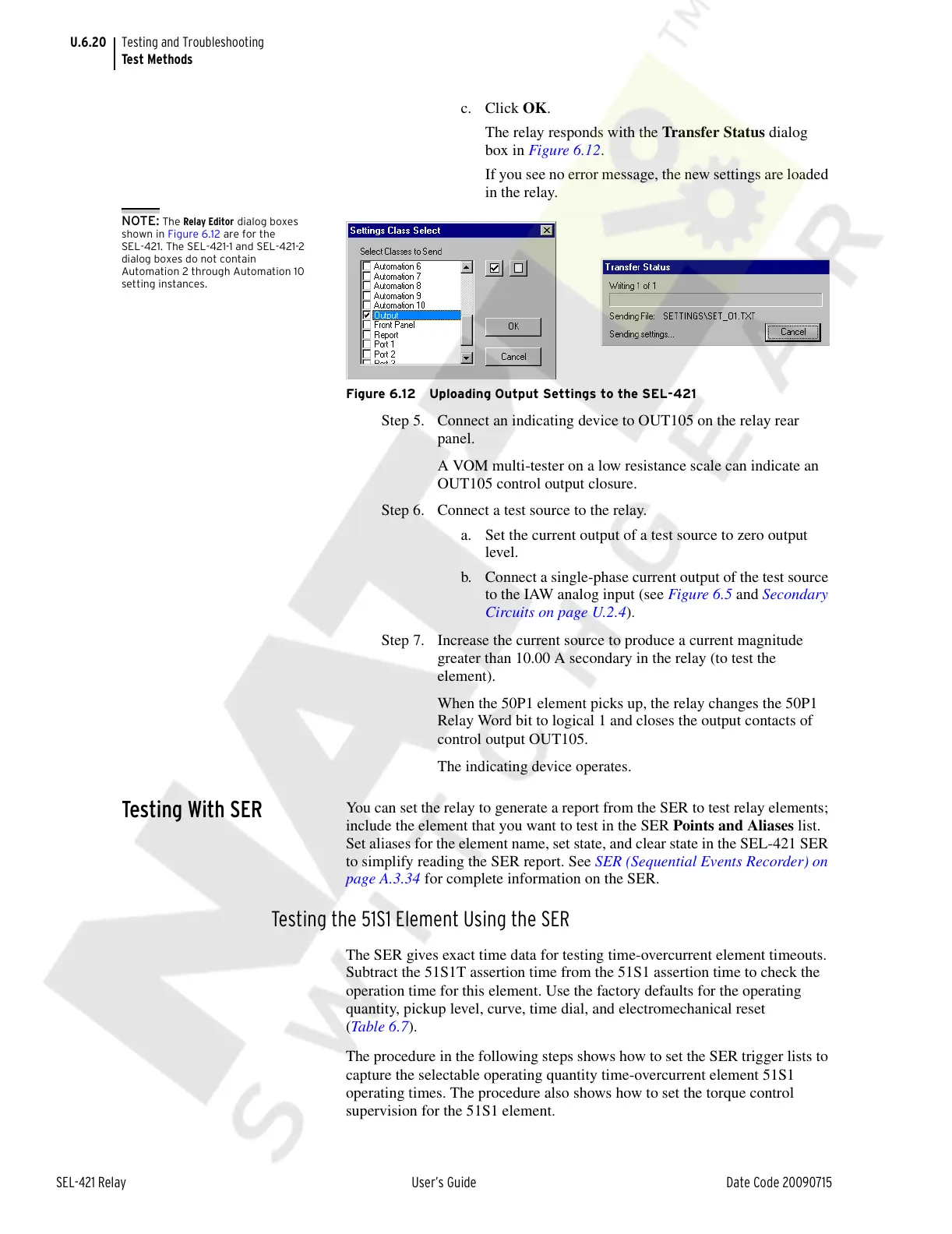

c. Click OK.

The relay responds with the Transfer Status dialog

box in Figure 6.12.

If you see no error message, the new settings are loaded

in the relay.

NOTE: The Relay Editor dialog boxes

shown in Figure 6.12 are for the

SEL-421. The SEL-421-1 and SEL-421-2

dialog boxes do not contain

Automation 2 through Automation 10

setting instances.

Figure 6.12 Uploading Output Settings to the SEL-421

Step 5. Connect an indicating device to OUT105 on the relay rear

panel.

A VOM multi-tester on a low resistance scale can indicate an

OUT105 control output closure.

Step 6. Connect a test source to the relay.

a. Set the current output of a test source to zero output

level.

b. Connect a single-phase current output of the test source

to the IAW analog input (see Figure 6.5 and Secondary

Circuits on page U.2.4).

Step 7. Increase the current source to produce a current magnitude

greater than 10.00 A secondary in the relay (to test the

element).

When the 50P1 element picks up, the relay changes the 50P1

Relay Word bit to logical 1 and closes the output contacts of

control output OUT105.

The indicating device operates.

Testing With SER

You can set the relay to generate a report from the SER to test relay elements;

include the element that you want to test in the SER Points and Aliases list.

Set aliases for the element name, set state, and clear state in the SEL-421 SER

to simplify reading the SER report. See SER (Sequential Events Recorder) on

page A.3.34 for complete information on the SER.

Testing the 51S1 Element Using the SER

The SER gives exact time data for testing time-overcurrent element timeouts.

Subtract the 51S1T assertion time from the 51S1 assertion time to check the

operation time for this element. Use the factory defaults for the operating

quantity, pickup level, curve, time dial, and electromechanical reset

(Tabl e 6 . 7 ).

The procedure in the following steps shows how to set the SER trigger lists to

capture the selectable operating quantity time-overcurrent element 51S1

operating times. The procedure also shows how to set the torque control

supervision for the 51S1 element.

Courtesy of NationalSwitchgear.com

Loading...

Loading...