Configuring the fieldbus

7.3 PROFIdrive profile for PROFIBUS and PROFINET

Inverter with CU230P-2 Control Units

120 Operating Instructions, 11/2013, FW V4.6.6, A5E02430659B AG

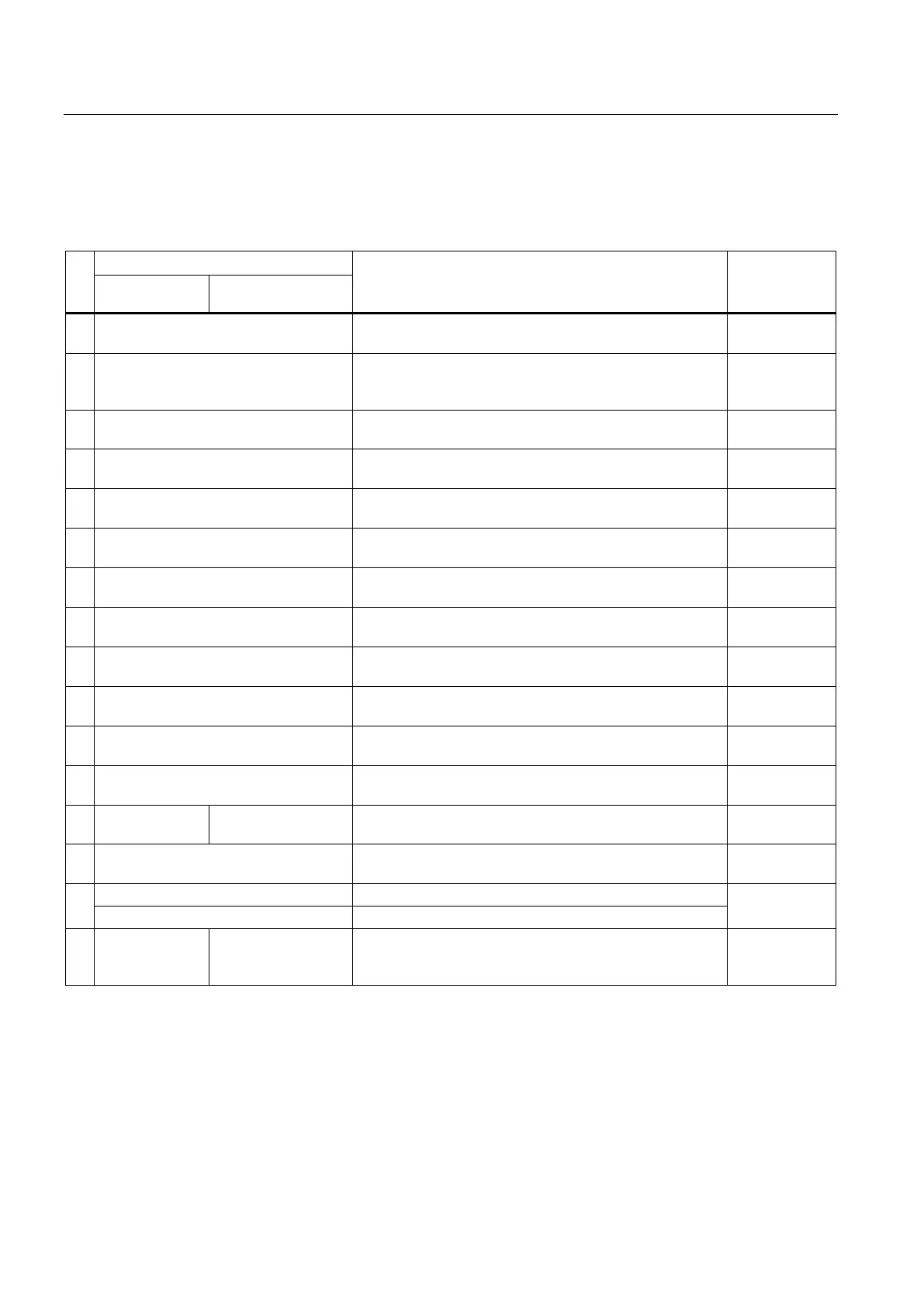

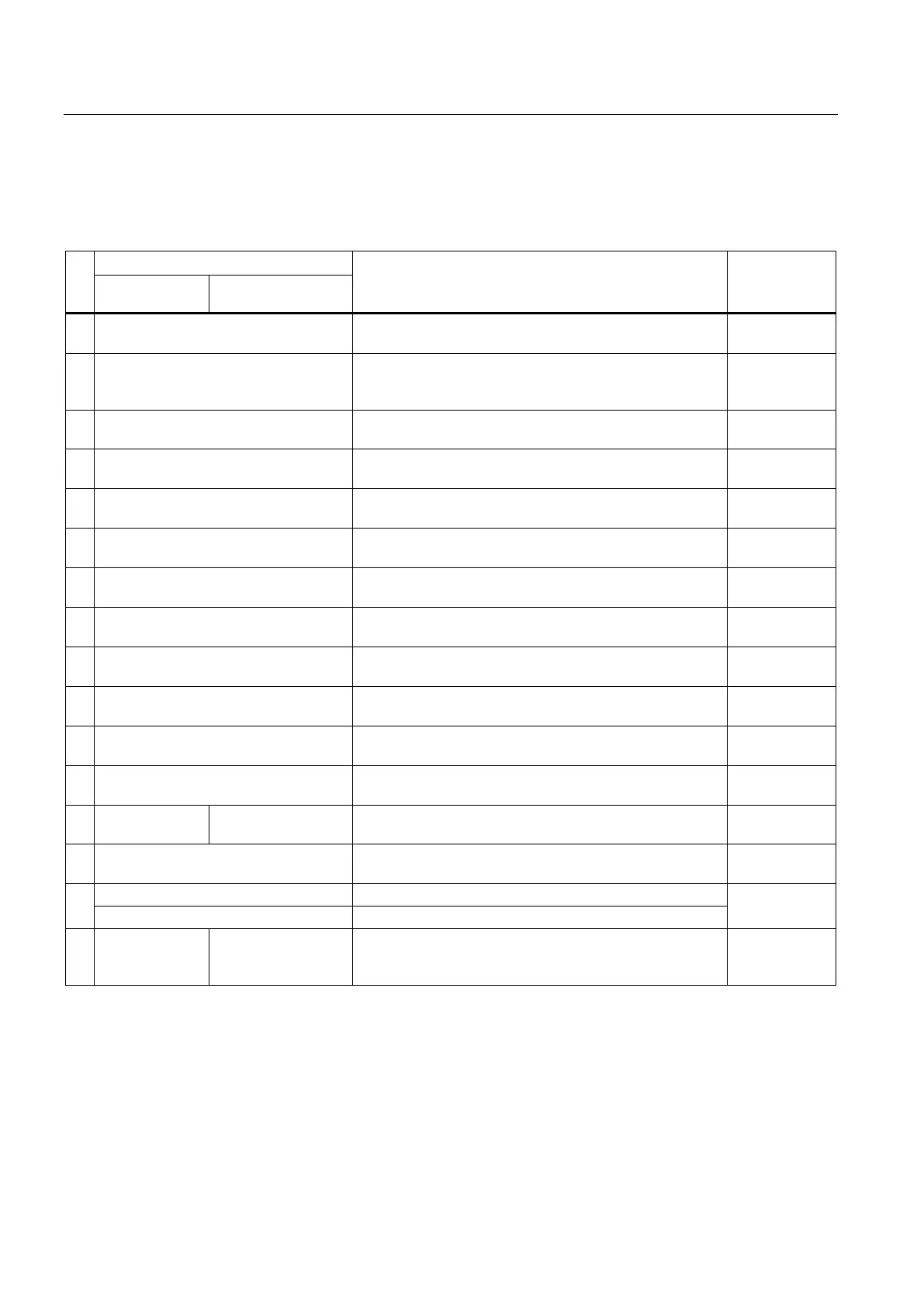

Status word 1 (bits 0 … 10 in accordance with PROFIdrive profile and VIK/NAMUR,

bits 11 … 15 specific to the inverter).

Signal

interconnection

in the inverter

0 1 = Ready to start Power supply switched on; electronics initialized; pulses

p2080[0] =

1 1 = Ready Motor is switched on (ON/OFF1 = 1), no fault is active.

With the command "Enable operation" (STW1.3), the

inverter switches on the motor.

p2080[1] =

r0899.1

2 1 = Operation enabled Motor follows setpoint. See control word 1, bit 3. p2080[2] =

3 1 = Fault active The inverter has a fault. Acknowledge fault using STW1.7. p2080[3] =

4 1 = OFF2 inactive Coast down to standstill is not active. p2080[4] =

5 1 = OFF3 inactive Quick stop is not active. p2080[5] =

6 1 = Closing lockout active It is only possible to switch on the motor after an OFF1

p2080[6] =

7 1 = Alarm active Motor remains switched on; no acknowledgement is

p2080[7] =

8 1 = Speed deviation within the

tolerance range

Setpoint / actual value deviation within the tolerance

range.

p2080[8] =

r2197.7

9 1 = Master control requested The automation system is requested to accept the inverter

p2080[9] =

10 1 = Comparison speed reached or

Speed is greater than or equal to the corresponding

p2080[10] =

11 0 = I, M or P limit reached Comparison value for current, torque or power has been

p2080[11] =

12 ---

1)

1 = Holding brake

Signal to open and close a motor holding brake. p2080[12] =

13 0 = Alarm, motor overtemperature -- p2080[13] =

14

1 = Motor rotates clockwise

Internal inverter actual value > 0

p2080[14] =

r2197.3

0 = Motor rotates counterclockwise

Internal inverter actual value < 0

15 1 = CDS display 0 = Alarm, inverter

thermal overload

p2080[15] =

r0836.0 /

1)

If you change over from another telegram to telegram 20, then the assignment of the previous telegram is kept.

Loading...

Loading...