Setting functions

8.5 Motor control

Inverter with CU230P-2 Control Units

Operating Instructions, 11/2013, FW V4.6.6, A5E02430659B AG

257

Optimizing the speed controller

Optimum control response - post optimization not required

You do not have to manually adapt the speed controller if, after the speed controller self

optimization, the motor manifests the following acceleration response:

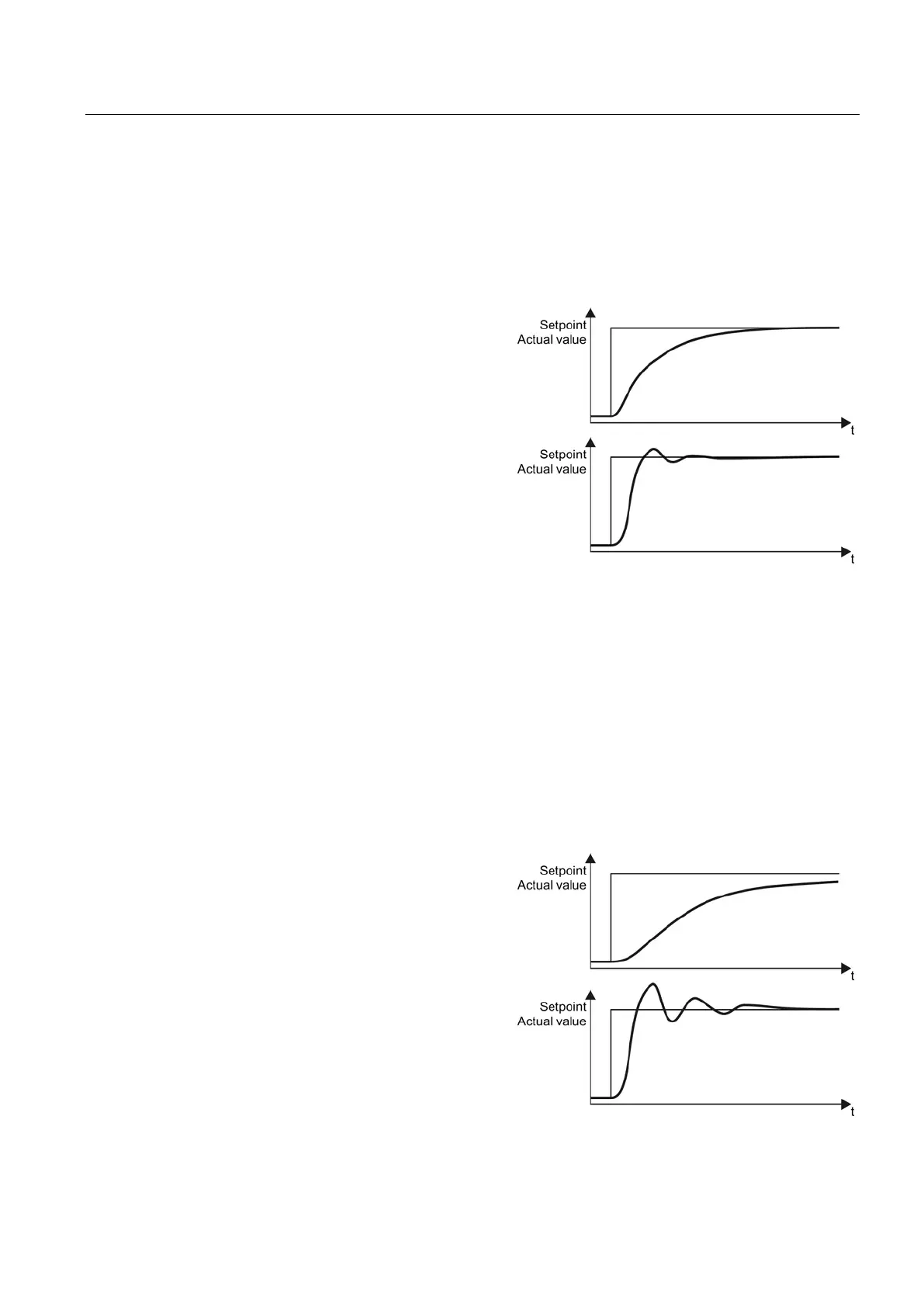

Optimum control response for

applications that do not permit any

overshoot.

The actual value approaches the

setpoint without any significant

overshoot.

Optimum control response for fast

correction and quick compensation of

noise components

.

The actual value approaches the

setpoint and slightly overshoots

(maximum 10% of the setpoint step).

Control optimization required

In some cases, the self optimization result is not satisfactory, or the inverter cancels the self-

optimization routine with a fault. Further, self optimization is not permissible in plants and

systems in which the motor cannot freely rotate.

In these cases you must manually optimize the speed controller.

The examples listed below show you which variables you can use to adapt the control

response.

The basic procedure is described in the following paragraph for STARTER and BOP-2.

● K

P

(p1470) Proportion share

● T

N

(p1472) Integration time

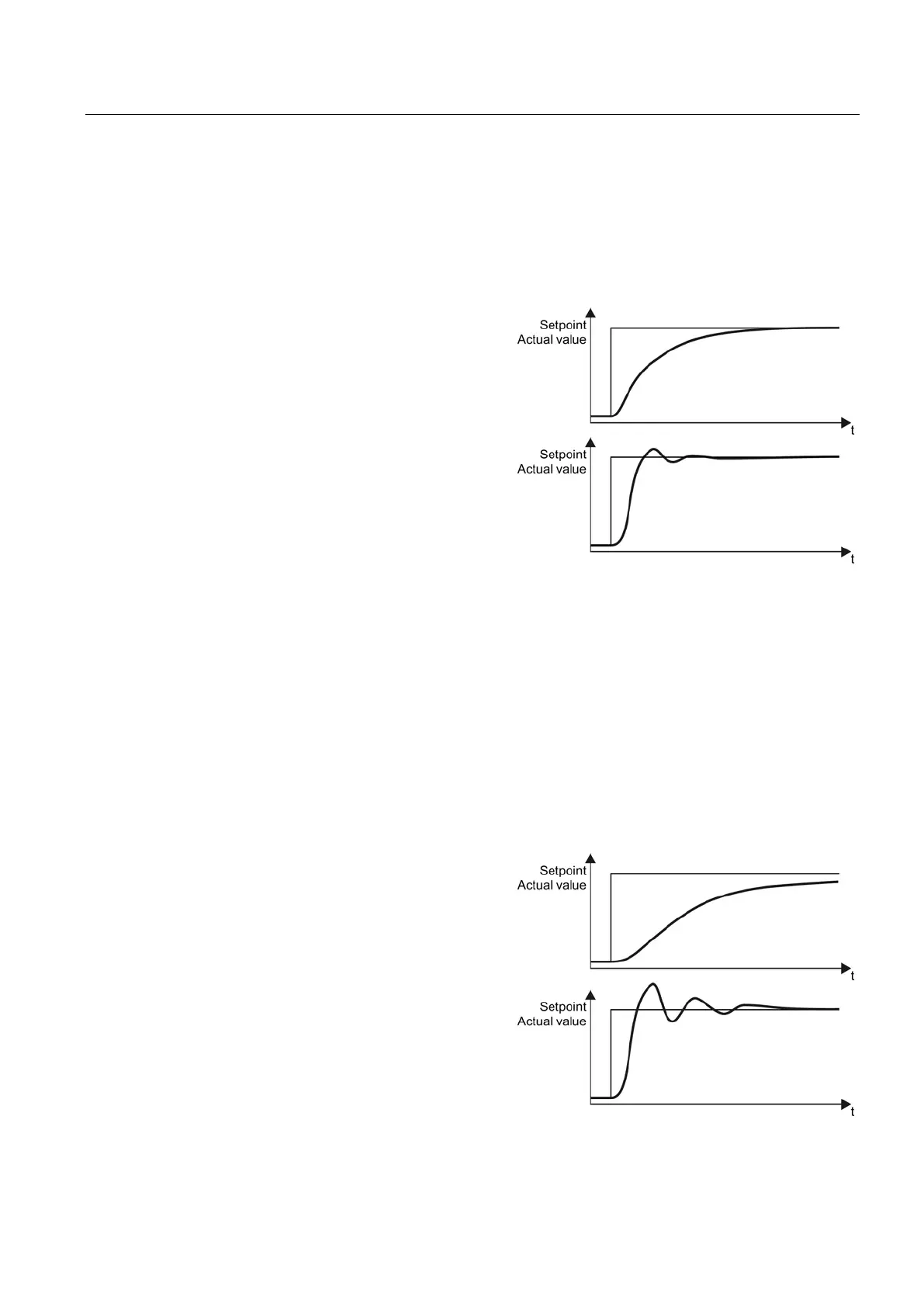

The actual value only slowly approaches

the setpoint

.

Increase the proportional component

K

P

and reduce the integration

time T

N

.

The actual value quickly approaches the

setpoint, but overshoots too much.

Decrease the proportional

component K

P

and increase the

integration time T

N

.

Loading...

Loading...