SECTION 6 ERROR MESSAGE

SERIES

Sysmex

CA-500

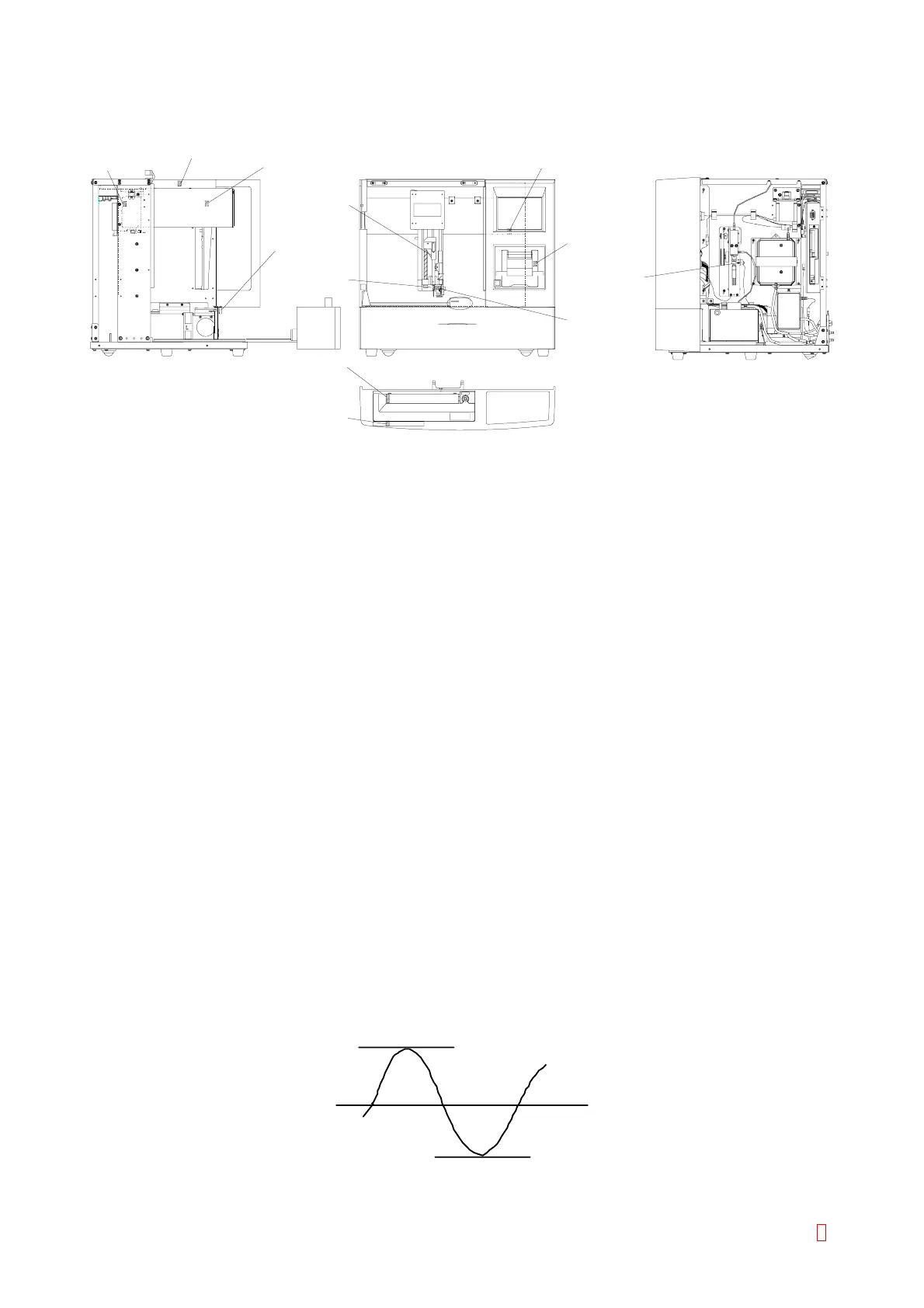

Cover Sensor

Barcode Reader

Home Position Sensor

Sampler Cover

Open Sensor

Z Axis Home

Position Sensor

Tube

Detection

Sensor

Liquid Serface

Sensor

Pipette Crash

Sensor

Paper Empty

Sensor

Y Axis Home

Position Sensor

X Axis Home

Position Sensor

STAT

Rack Detection Sensor

H

O

S

T

Syringe

Home Position

Sensor

Figure 6-1: Sensor Positions

6.1 PRESSURE ERRORS

6.1.1 Pressure Pump Error

Monitor Timing: At time of each analysis start and/on rinse start, just before opening SV

Monitor Method: Monitoring 225 g/cm

2

r 10% by the comparator

CA-500’s Action: Emergency stop

(1) Probable Cause

1. The rinse bottle is not connected.

2. The cap of rinse bottle is removed.

3. SV failure

4. Pressure pump failure

5. Perforations (pinhole) in the hydraulic line.

6. Pressure sensor failure

7. Sensor circuit failure

8. Drive circuit failure

(2) Confirmation by the Operator

1. Properly connect the tube.

2. Securely tighten the bottle cap.

(3) Confirmation by the Service Engineer

1. When SV is faulty, rinse solution keeps flowing out from sample probe or rinse cup. Replace faulty SV.

2. When the hydraulic line has no failure, the pressure pump or related electronic circuit has a trouble.

If replacement of the pressure pump allows the pressure adjustment, the pressure pump is failed; if not,

the electronic circuit is failed.

3. The pressure pump turn ON or OFF at the pressure 250 g/cm

2

. If the pump does not start operating

even when the cap of rinse bottle is removed, the pump or its drive circuit is failed.

Measure voltage at the connector of pump by the DVM. If AC 100 V ± 15% is displayed, the pump is

failed; if not, the drive circuit is failed.

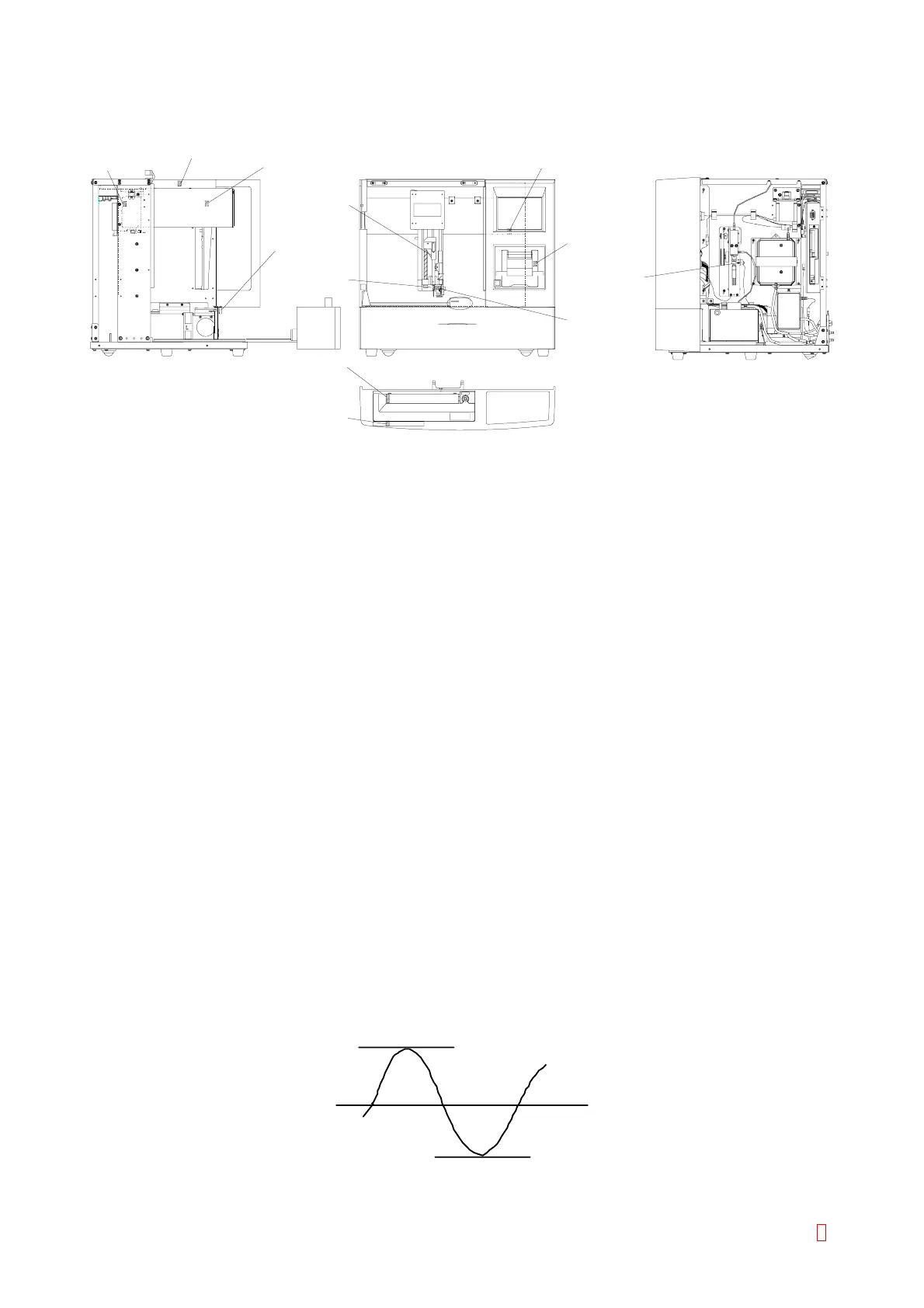

141V peak

-141V peak

Figure 6-1-1: Normal Oscilloscope Wave

CA-500 Series S/M 6-1 Revised December 2001 8

Loading...

Loading...