6.5 DISPENSING ERRORS

6.5.1 No Sample (Rack Position)

Monitor Timing: At sample aspiration

Monitor Method: Detects liquid level by the capacitance liquid level detection sensor.

CA-500’s Action: The sample is not analyzed.

(1) Probable Cause

1. Specimens are not placed.

2. Plasma volume is insufficient.

3. Failure of sample probe

4. Failure of PCB No. 2134

5. Failure of Y-Z relay harness

6. Failure of PCB No. 9260

7. Failure of X axis wiring cord

8. Failure of wiring cord (flat cable)

9. Failure of PCB No. 6362

(2) Confirmation by the operator.

1. Place the specimen.

2. Check whether the sample location (rack number) matches its registration or not.

(3) Confirmation by Service Engineer.

1. Monitor the liquid sensor function in the Service mode. If it does not function, the followings are

conceivable. Since the liquid level detection is latched each time, reset it on the screen to check.

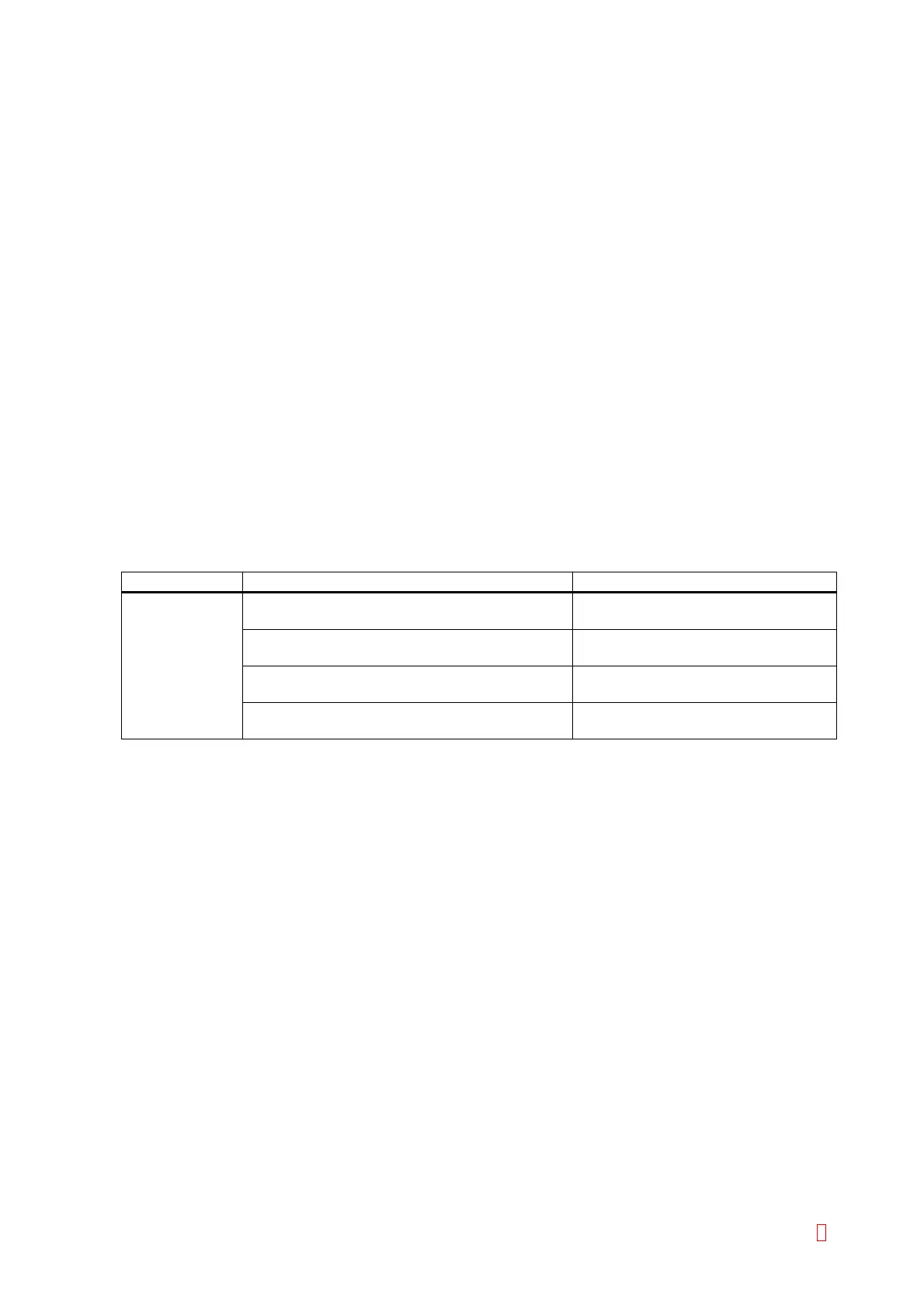

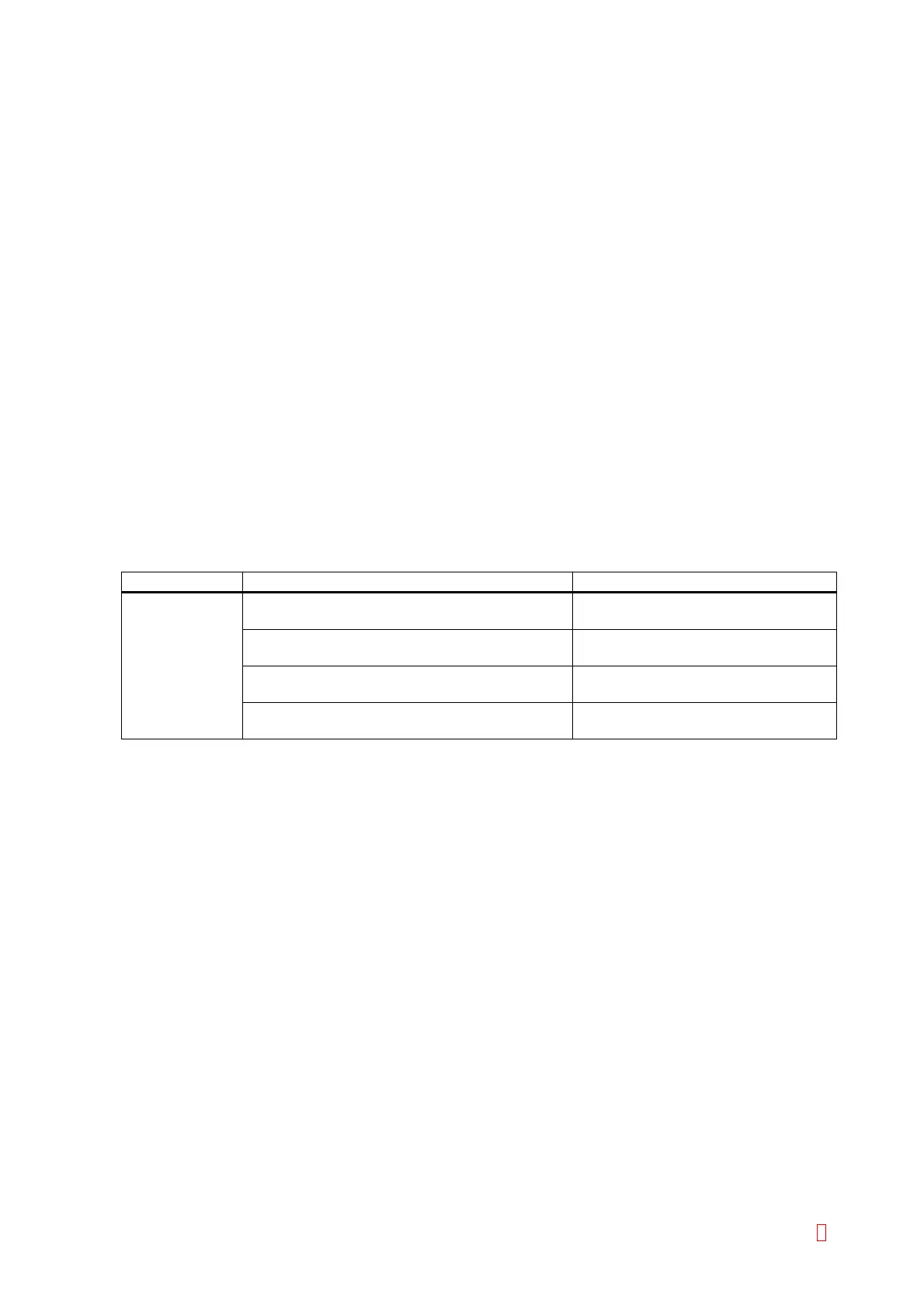

Suspect Part Test Points Expected Value

Liquid Sensor CN2 (PCB No. 2134) pin 1 is touched with

tweezers or the like

Indicator on LCD changes from

white circle to black circle

CN1 (PCB No. 2134) pin 16 (GND) and pin 5 5 V when probe touches liquid

surface

CN1 (PCB No. 9260) pin 16 (GND) and pin 5 5 V when probe touches liquid

surface

CN105 (PCB No. 6362) pin 13 (GND) and pin

2

5 V when probe touches liquid

surface

CA-500 Series S/M 6-14 Revised December 2001 8

Loading...

Loading...