CARE AND MAINTENANCE 7

MHL380 D 7.31

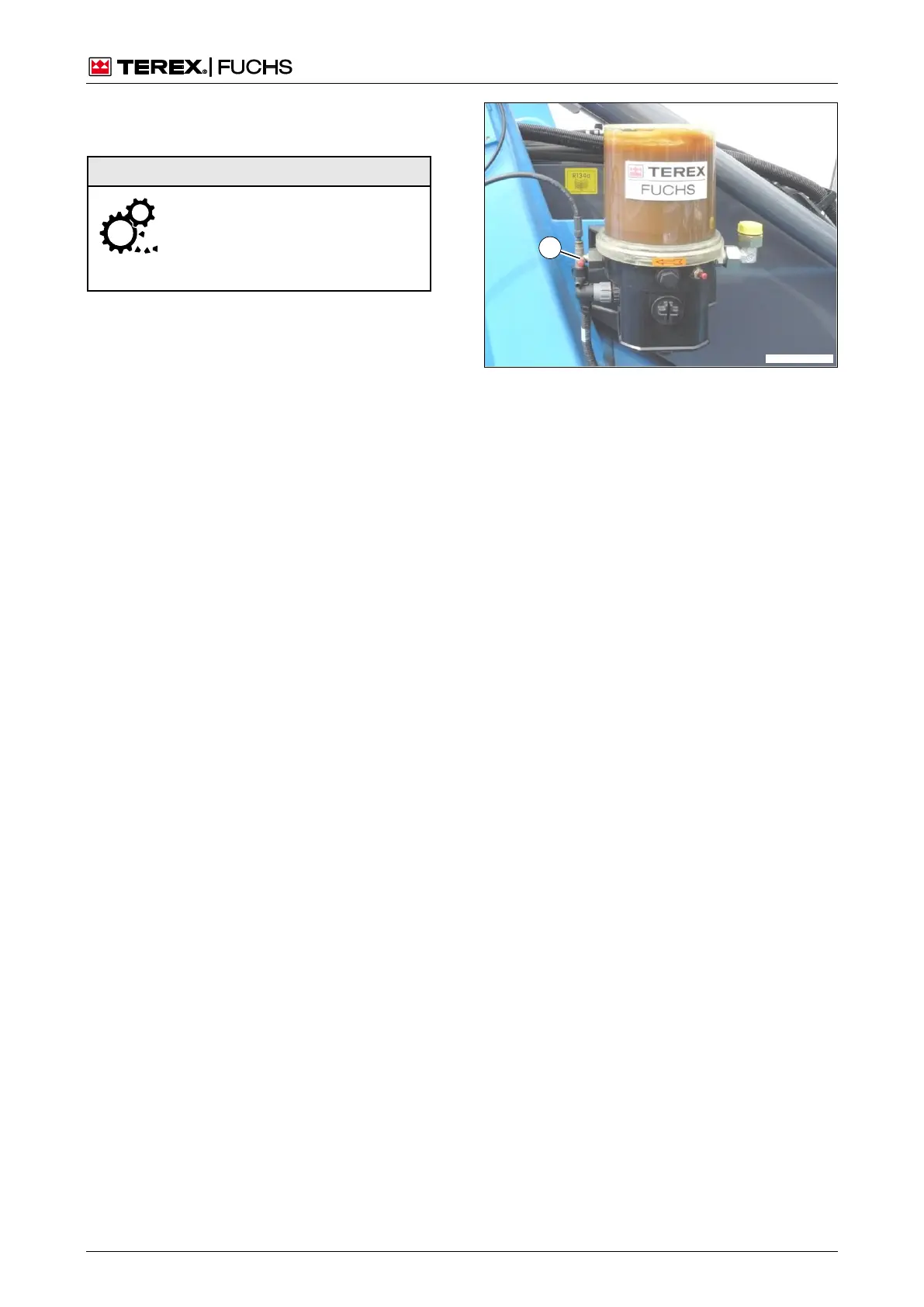

7.7.4.2 Lubrication when lubricating

pump is faulty

If the lubricating pump is defective,

it may cause serious bearing

damage. The lubricating pump

must therefore be repaired imme-

diately.

If the loading machine starts running again on

its own accord for a short period of time, the

lubrication system behind the lubricating

pump should be supplied with grease manual-

ly.

Lubrication interval: every 4 operating hours

►

Attach filler pump to grease nipple (183/1).

►

Pump in lubrication grease until fresh lubri-

cation grease escapes from the boom

bushings and dipperstick bearing, creating

a collar of grease.

If the machine has been operated for sev-

eral days without the lubricating pump,

grease must be pumped in until fresh

grease escapes on all bearing points.

Fig. 183 Grease nipple

Loading...

Loading...