CARE AND MAINTENANCE 7

MHL380 D 7.67

7.9.13.3 Hydraulic oil – return filter

h Replace as described in chapter 7.8.3

Maintenance and inspection plan.

Replace the filter element after a

test run if there is damage to the

hydraulics or following major repair

work.

Faulty hydraulic attachments can

reduce the service life of the return

filter.

The pressing force of the return fil-

ter must be routinely checked every

time the return filter is opened or

closed.

Replacing the filter element

Danger of injury due to falling

• Before replacing the filter ele-

ment, make sure that suitable

equipment for this purpose (e.g. a

pedestal) is at hand.

In an emergency: Administer first

aid, seek treatment from a doctor

The part must be replaced as soon as the

indicator (220/39) lights up continuously. The

indicator may light up briefly, but this is cir-

cumstantial and is usually caused by the en-

gine speed being increased too quickly.

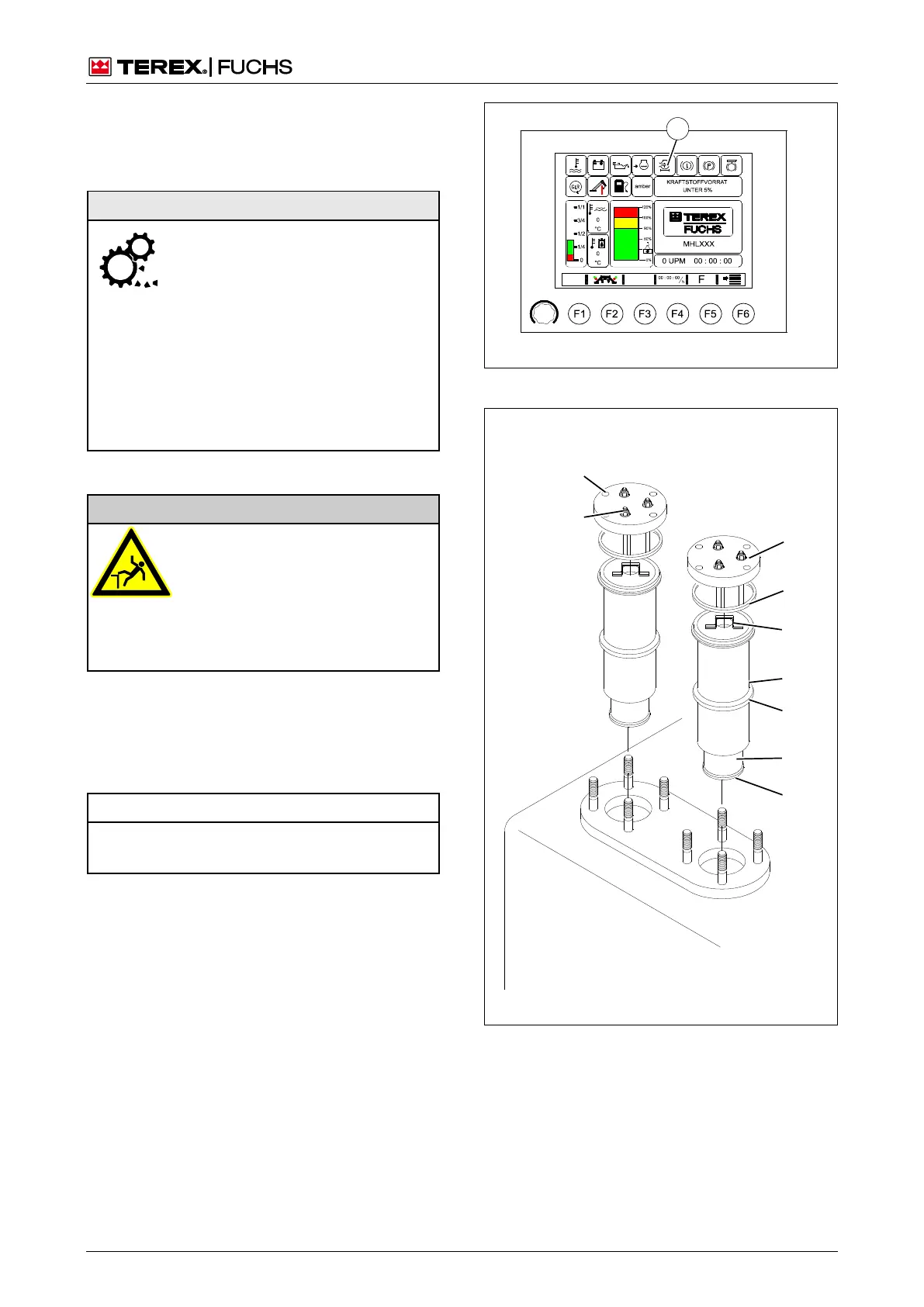

The same procedure applies to both return fil-

ters!

►

Switch off the diesel engine.

►

Use a tool to loosen the cover (221/1) of

the return filter and then unscrew it.

►

Check the condition and seal of the cover.

►

Remove the return filter on the bow (221/6)

from the hydraulic tank.

►

Clean the O-ring (221/3) between the hy-

draulic tank and the return filter cover.

Fig. 220 Return filter clogging

Fig. 221 Return filter

Loading...

Loading...