PROCEDURE

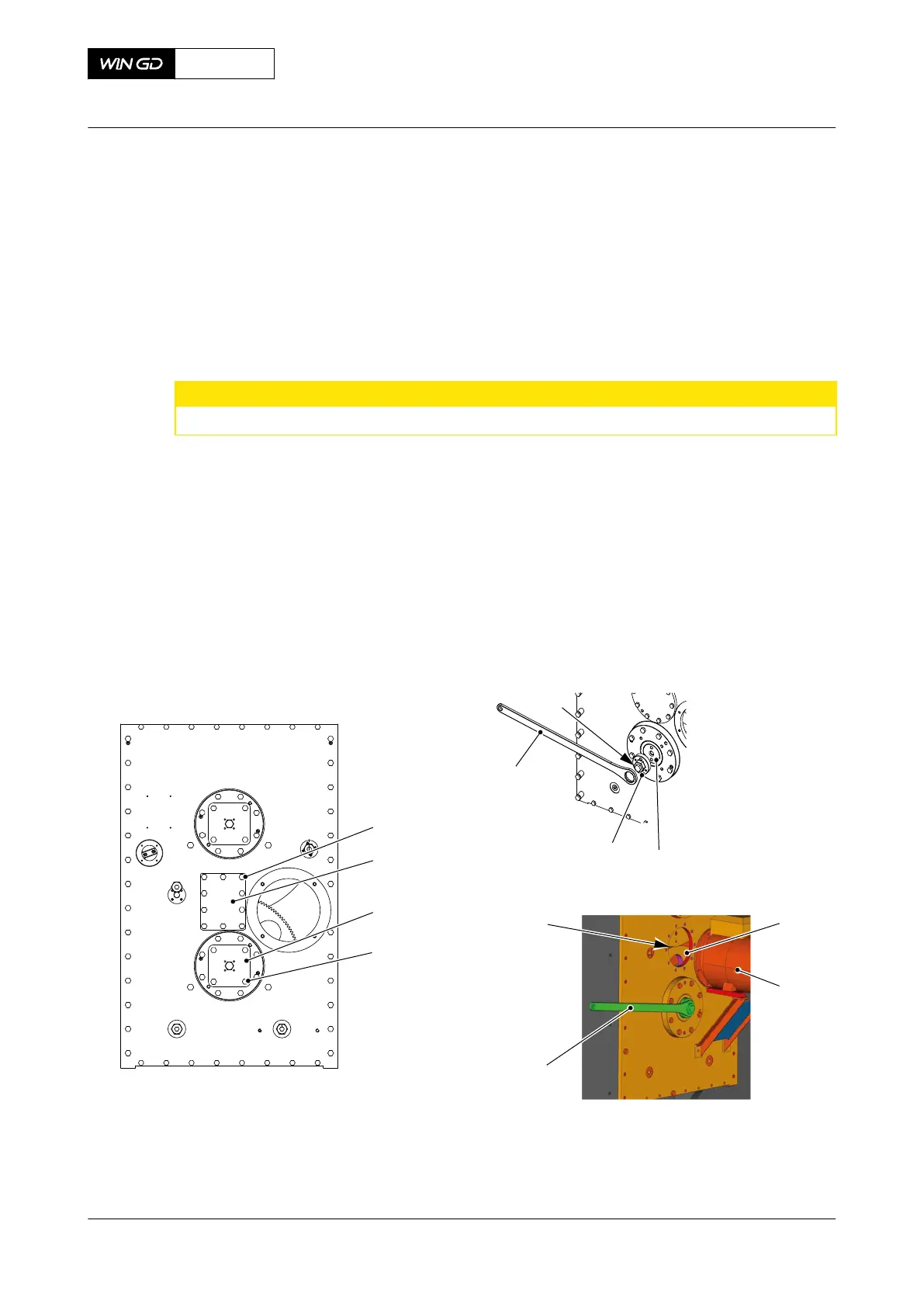

1 Make sure that the new bearing (007, Figure 12-19) is clean, dry and in good condition.

2 Apply Molykote D to the bearing surface.

3 Attach the lifting tool (003) to the bearing (007).

4 Tighten the screw (004).

5 Attach the lever chain hoist (002) to the lifting tool (003) and the eye bolt (001).

6 Apply Loctite No. 640 to the applicable surface of the bearing (007).

7 Apply Molykote D to the bearing surface of the pin (009).

8 Operate the lever chain hoist (002) to get the bearing (007) to the correct height.

9 Attach the screw (005) and the nut (006) through the bearing (007) into the pin (009).

10 Tighten the screw (005).

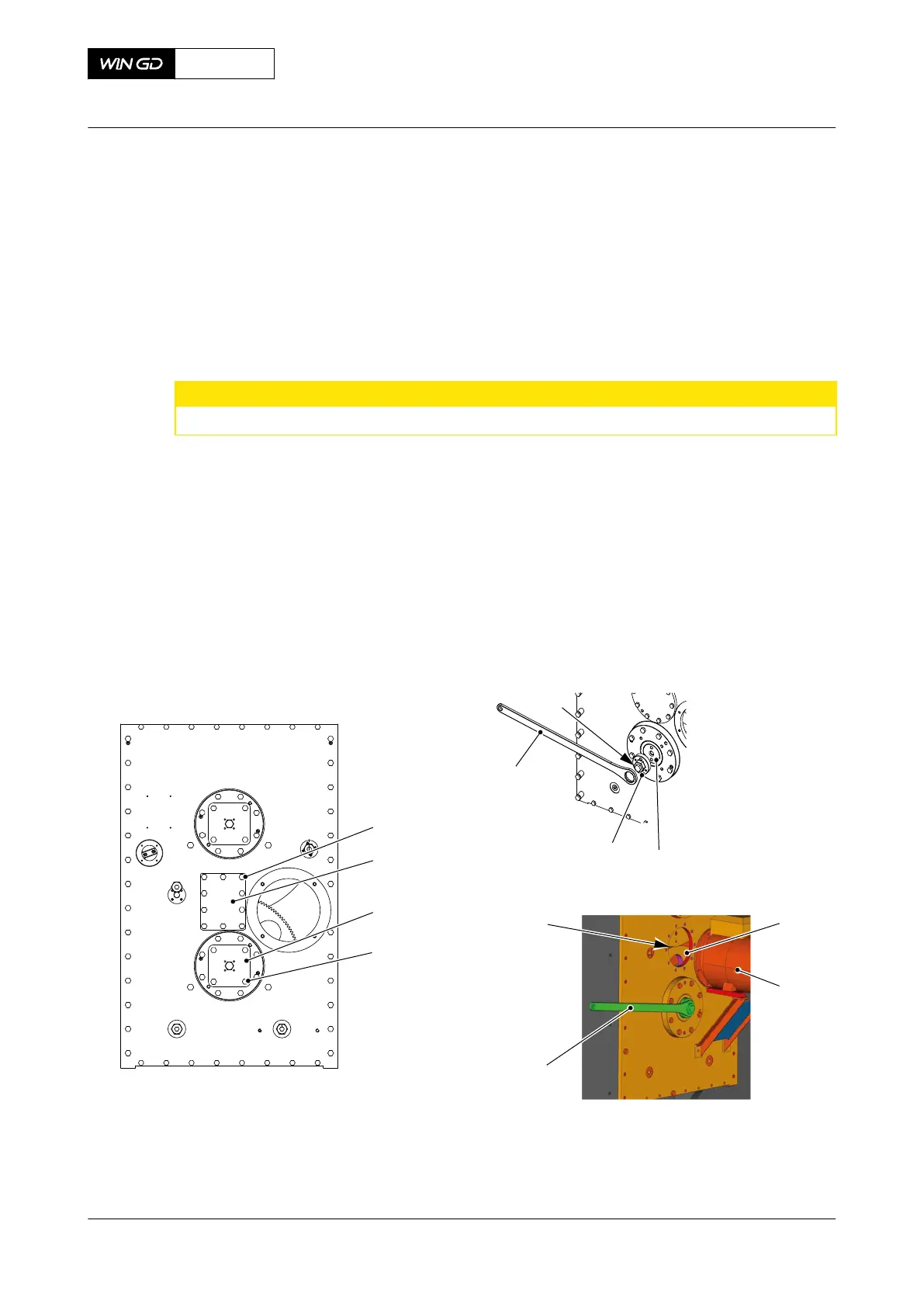

11 Find the taper bin holes in the column (008).

Fig 12-19 Bearing - install

002

ENGINE

SIDE

00582

001

003

005

006

009

008

Molykote D

Loctite 640

002

003

004

005

010

004

007

007

12 Turn the bearing (007) until the taper pin holes are at 90° to the holes in the column

(008).

13 Tighten the nut (006). Make sure that the bearing is in the correct position in the column

(008).

14 Remove the lifting tool (003).

15 Attach the bearing (007) with four of the eight bolts (010). Do not tighten the bolts.

CLOSE UP

• None

X62DF

AA00-7758-00AAA-720A-A

Maintenance Manual Integrated electric balancer - install the bearing (engine side)

Winterthur Gas & Diesel Ltd.

- 711 - Issue 002 2020-10

Loading...

Loading...