Copyright Winterthur Gas & Diesel Ltd. All rights reserved. By taking possession of the drawing, the recipient recognizes and honors these rights. Neither the whole nor any part of this drawing may be used in any way for construction, fabrication, marketing or any other purpose nor copied in any way nor made accessible to third parties without the previous written consent of Winterthur Gas & Diesel Ltd.

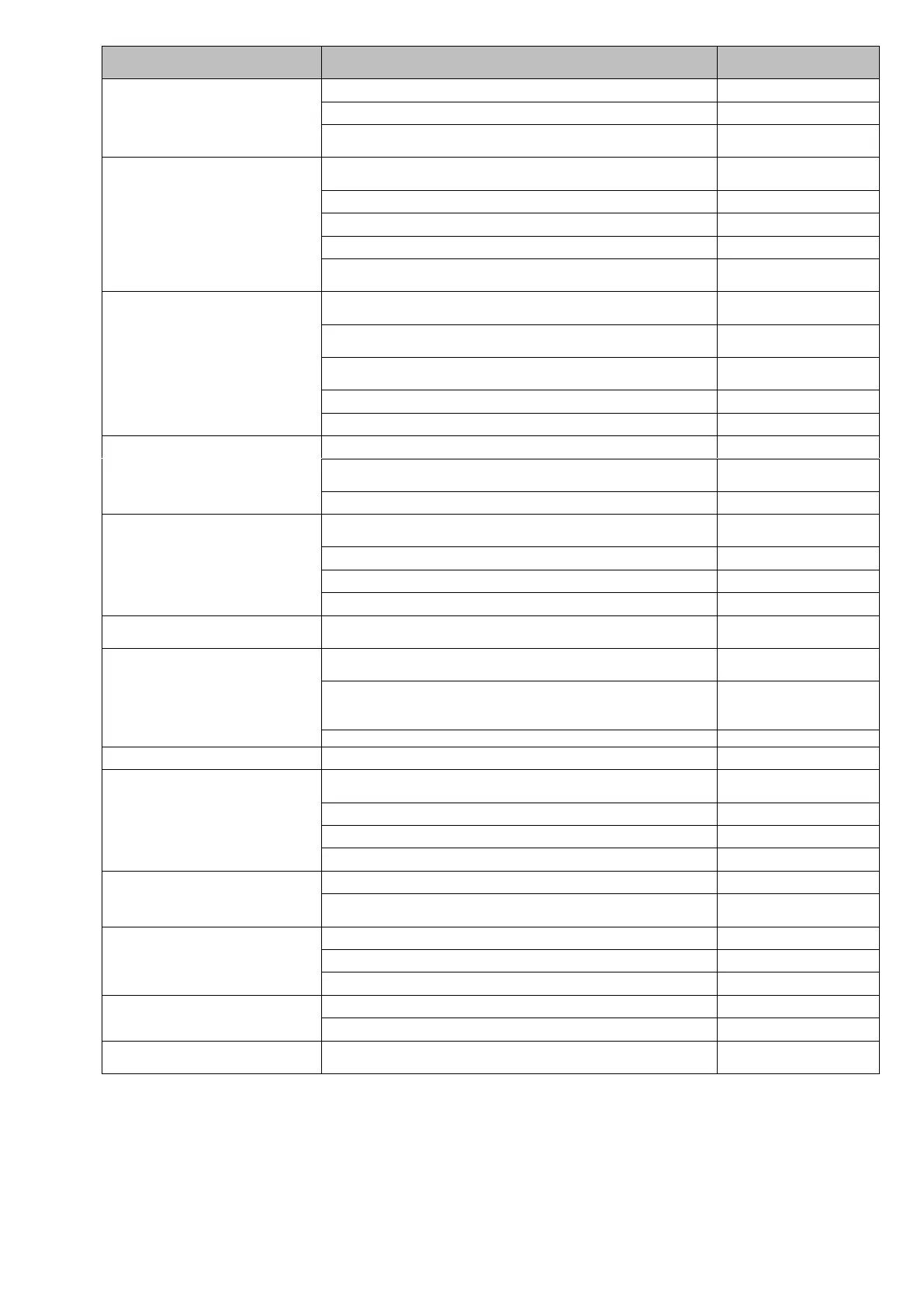

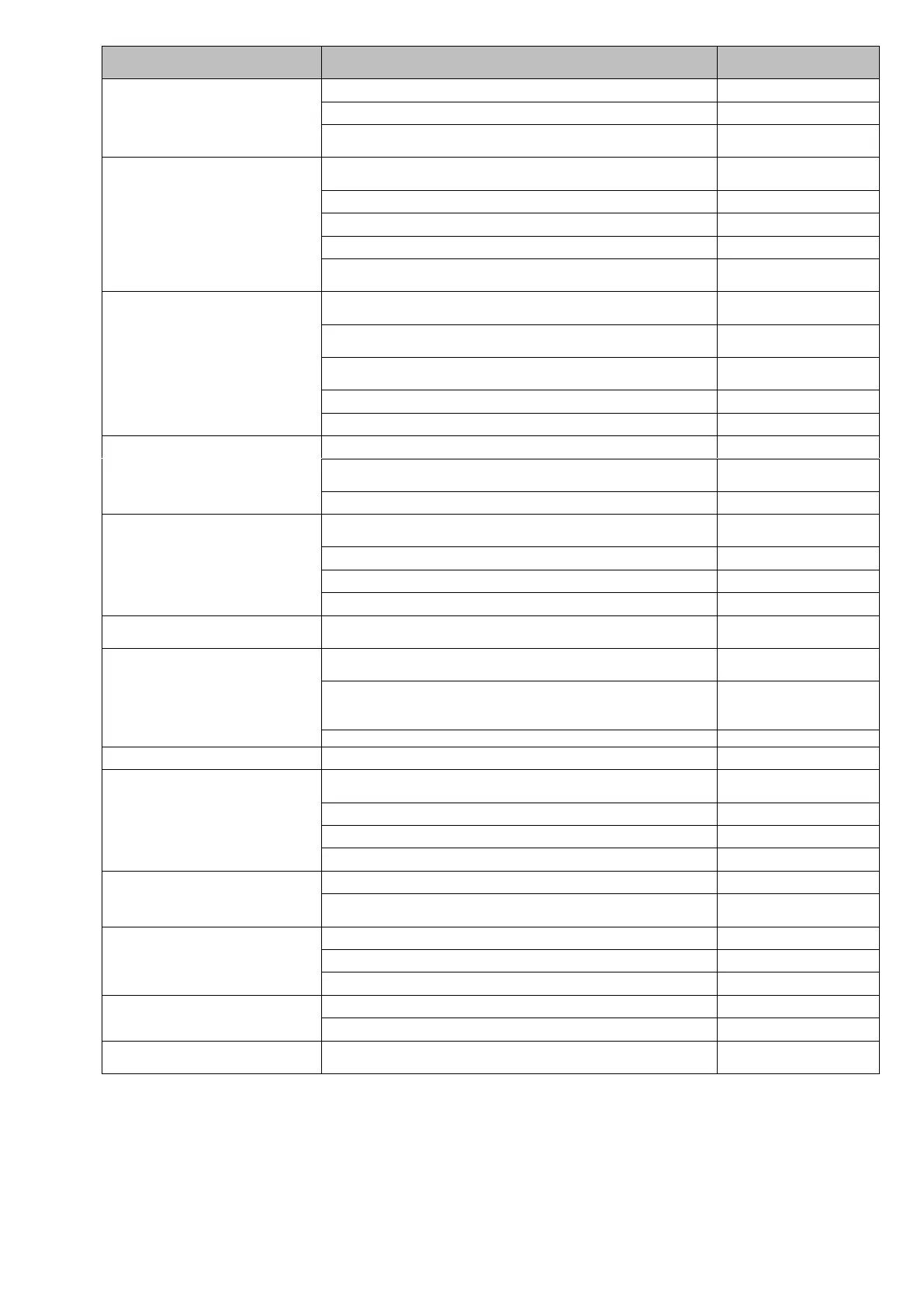

Intervals & Lifetime

[operating hours]

Check pinion and driving wheels to servo oil pump drive

Check filter below the plug in the compensator for particles

Estimated lifetime: supply unit pinion bearing bushes

90000 (replacement if

required)

Camshaft, check running surface of cams, rollers & roller guides (first time

after 500 Op. h)

Check pinion and driving wheels to fuel oil pump drive

Camshaft, check bearing clearances at random position

Camshaft, check thrust bearing clearances

Estimated lifetime: supply unit camshaft bearings

90000 (replacement if

required)

Pilot fuel supply unit (Group 87xx)

Lubricate the flexible coupling of the pilot fuel pump

1500 - 3000 (regardless of

the operating mode)

Replace the pilot fuel pump

24000 (regardless of the

operating mode)

Replace the pilot fuel oil filter cartridges ( the cartridges must be replaced

earlier if the pressure difference indicator shows high pressure increase).

1000 (regardless of the

operating mode)

Clean the wire gauze and filter housing.

Estimated lifetime: Pilot fuel pump

Random flow check of lubricating oil

Do a check of the fuel oil leakage from the fuel pump cover (the O-ring in

the non-return valve can become weak)

Remanufacture fuel pump or overhaul on board

Fuel pressure control valve (PCV,

group 55xx)

Check shut-down function (see Operation Manual 4003-1)

Removal and pressure check

only necessary if PCV fails

Estimated lifetime: Fuel pressure control valve (PCV)

Fuel overpressure safety valve /

relief valve (Group 55xx)

Function check on test bench

Flow limiting valve (FLV, group 55xx)

Inspect and clean piston rod

6000 (12000 in case of

MGO usage)

Piston replacement (piston spare kit)

Subject to actual conditions,

expected lifetime 48’000 (or

6~7 years)

Expected lifetime FLV housing

Servo oil rail (Group 56xx)

Replace hoses (at least every 5 years)

Exhaust valve control unit (Group

56xx)

Random check of piston and slide rod

Check VCU last chance filter

Replace 4/2 solenoid valve

Estimated lifetime: Exhaust valve control unit

Fuel pump actuator (Group 55xx)

Check for free movement of regulating linkage, lubricate movable parts

Replace fuel pump actuator with a new item or a remanufactured fuel

pump actuator from maker

Scavenge air receiver (Group 64xx)

Check and clean air flaps

Make sure water drain pipes and orifices are not blocked

Turbocharger (Group 65xx)

Wash-cleaning of blower in service

Wash-cleaning or dry cleaning of turbine in service

Maintenance Intervals /

Lifetime

Loading...

Loading...