General Troubleshooting 4-17

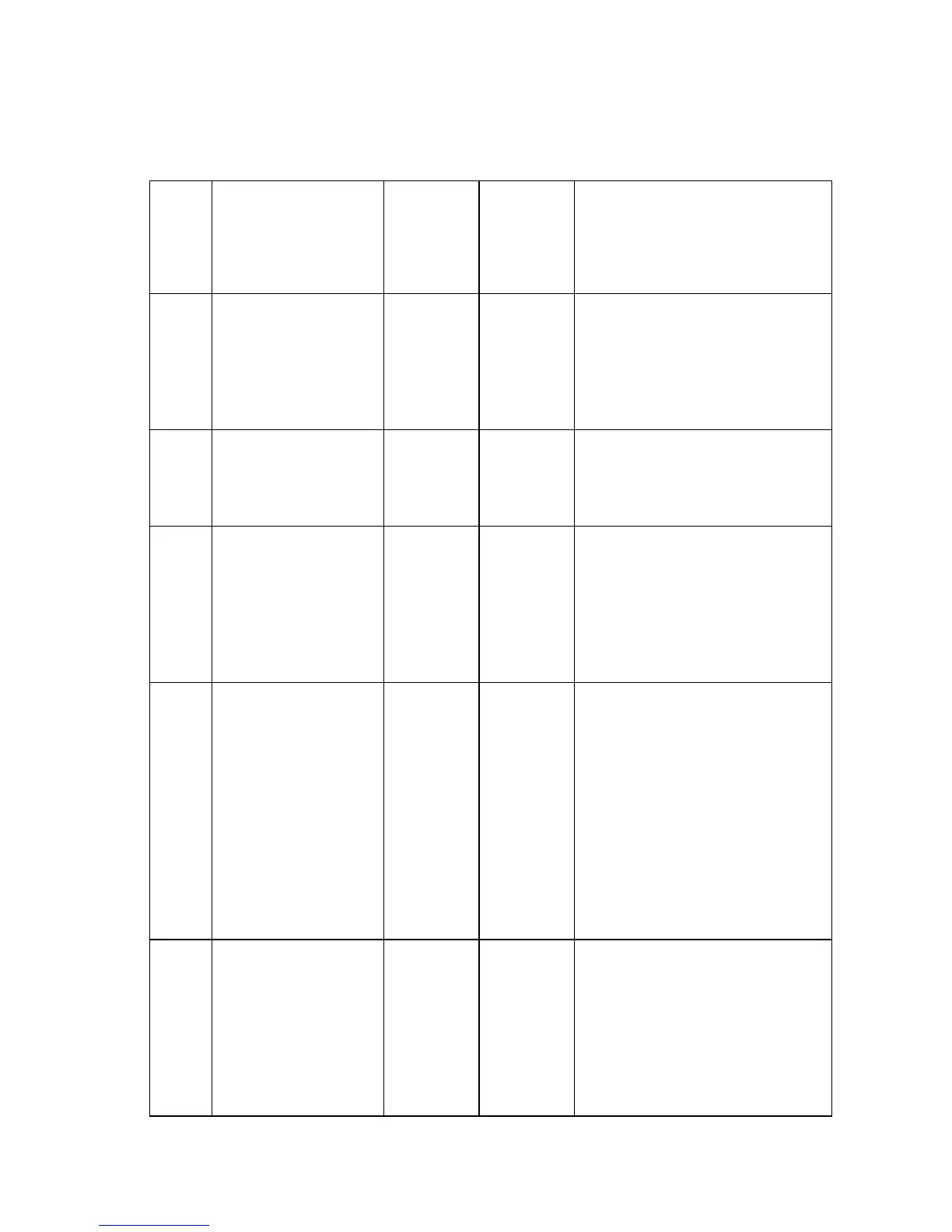

Check Shafts Menu

Deskew Shaft

Runs the media path drive train and engages the deskew clutch on the fly then disengages the

clutch. The test is repeated in both directions to determine clutch characteristics, steady state

drive requirements, bearing status, etc.

R# Definition

Typical

Value

(8400)

Typical

Value

(8500/

8550) Actions

0 Time to CCW On

peak fe (sec).

0.01 to

0.04

.01 to.04 Reports how long it takes the MP

motor servo system to react to

the sudden addition of the

deskew shaft load.

Larger values may show a

slipping/slow to engage clutch.

1 CCW On peak fe. 540 to

750

2.0 to 8.0 Reports peak effort needed to

accelerate the deskew shaft

load. A smaller value could

indicate a slipping clutch.

2 CCW On fe settling

time (sec).

0.017 to

0.21

0 to .2 Reports the time it takes the MP

motor servo system to "settle

down" after the sudden addition

of the deskew shaft load.

A longer time could indicate a

looseness in the deskew shaft

assembly or a slipping clutch.

3 CCW On average fe. 250 to

600

1.0 to 2.5 Reports the average effort

required to rotate the deskew

shaft in the CCW direction at a

constant velocity.

An unusual value could indicate

a difference in the composition

and/or number of the rollers, the

nip pressure, or out of range

mechanical dimensions due to

wear or contamination (such as

paper dust increasing the

effective diameter of a roller).

4 CCW On fe ripple. 115 to

360

0 to 2.0 Reports the variation of effort

required to rotate the deskew

shaft in the CCW direction at a

constant velocity.

A larger value could indicate

particles in the gears or non

uniform contamination of a roller

(causing a lump).

Loading...

Loading...