2-24 Phaser 8400/8500/8550 Color Printer

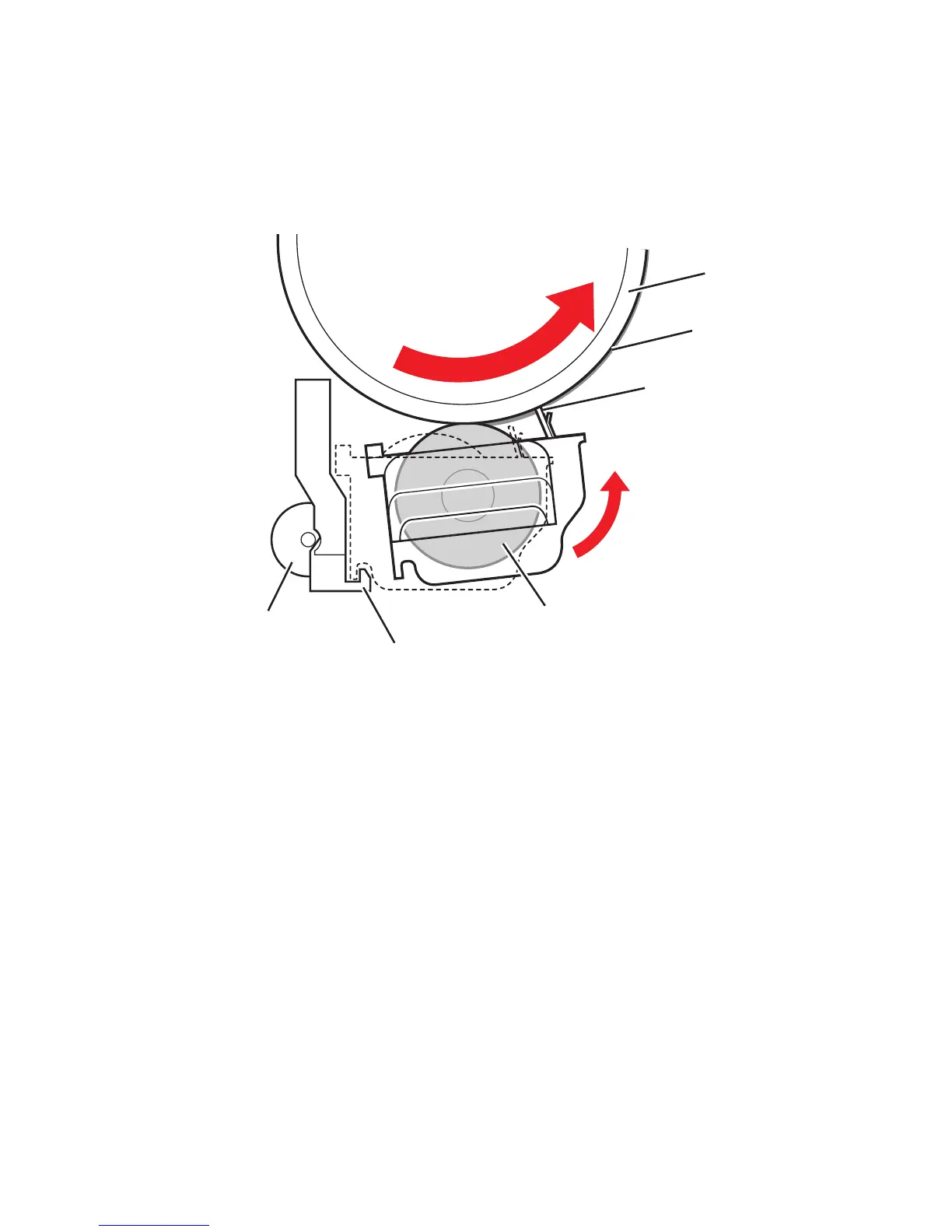

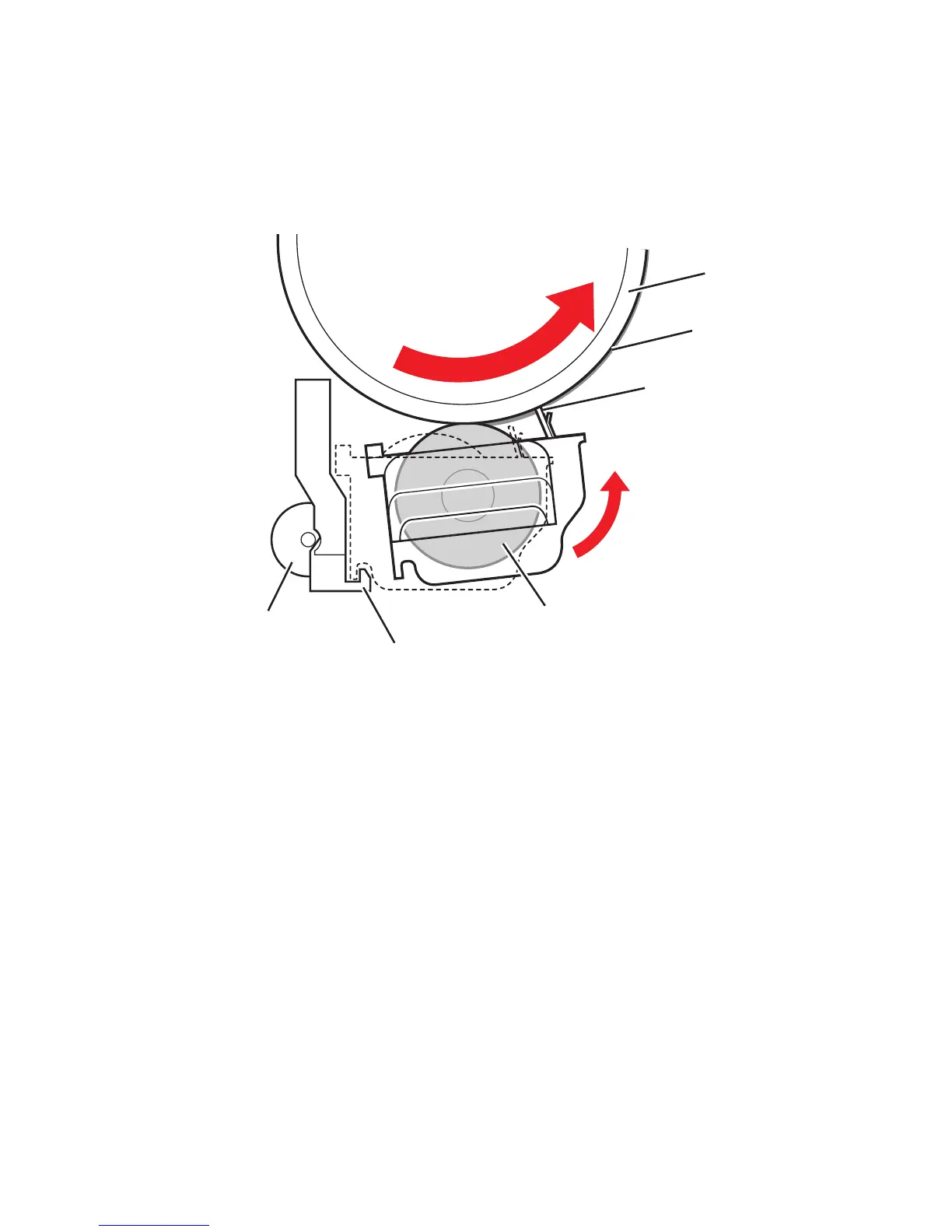

Drum Preparation

To prepare the drum, the drum maintenance system applies a thin coating of silicone

to the surface of the drum. The process drive first rotates the drum maintenance

camshaft. As the drum rotates, the cams on the ends of the camshaft push against

followers on each side of the drum maintenance system, forcing the oil roller and

blade against the drum. The saturated roller evenly distributes oil on the drum as it

rotates.

Printing

To print, the drum begins to rotates at a speed dependent upon print resolution. As the

drum reaches the correct speed, the jets begin to fire to deposit the image on the oiled

portion of the drum. As the jets fire, the printhead moves from right to left to complete

the image on the drum.

When printing, the printer performs a “six-jet interlace”, in which each jet lays down

a particular number of pixel columns, depending on the print resolution. Each jet lays

down one pixel column for each drum rotation, which varies from eight to 16

rotations, depending on the print resolution. Interlacing “averages out” the variability

between jets as it interlaces each jet with other jets. In some test prints, the printhead

moves to the right and lays down 309 parallel bands of ink. Each band is composed of

15 pixel columns of dots from an individual jet.

Jet substitution allows a better performing jet to be used in place of a missing or

poorly performing neighboring jet. When the printer is in the jet substitution mode,

the printhead makes a second, right to left movement to deposit the pixel columns of

the substituted jets. See "Jet Substitution Mode" on page 6-10.

s8500-016

Drum

Maintenance Roller

Drum Maintenance Pivot Plate

Drum Maintenance

Camshaft

Blade

Oil on Drum

Loading...

Loading...