4-44 Phaser 8400/8500/8550 Color Printer

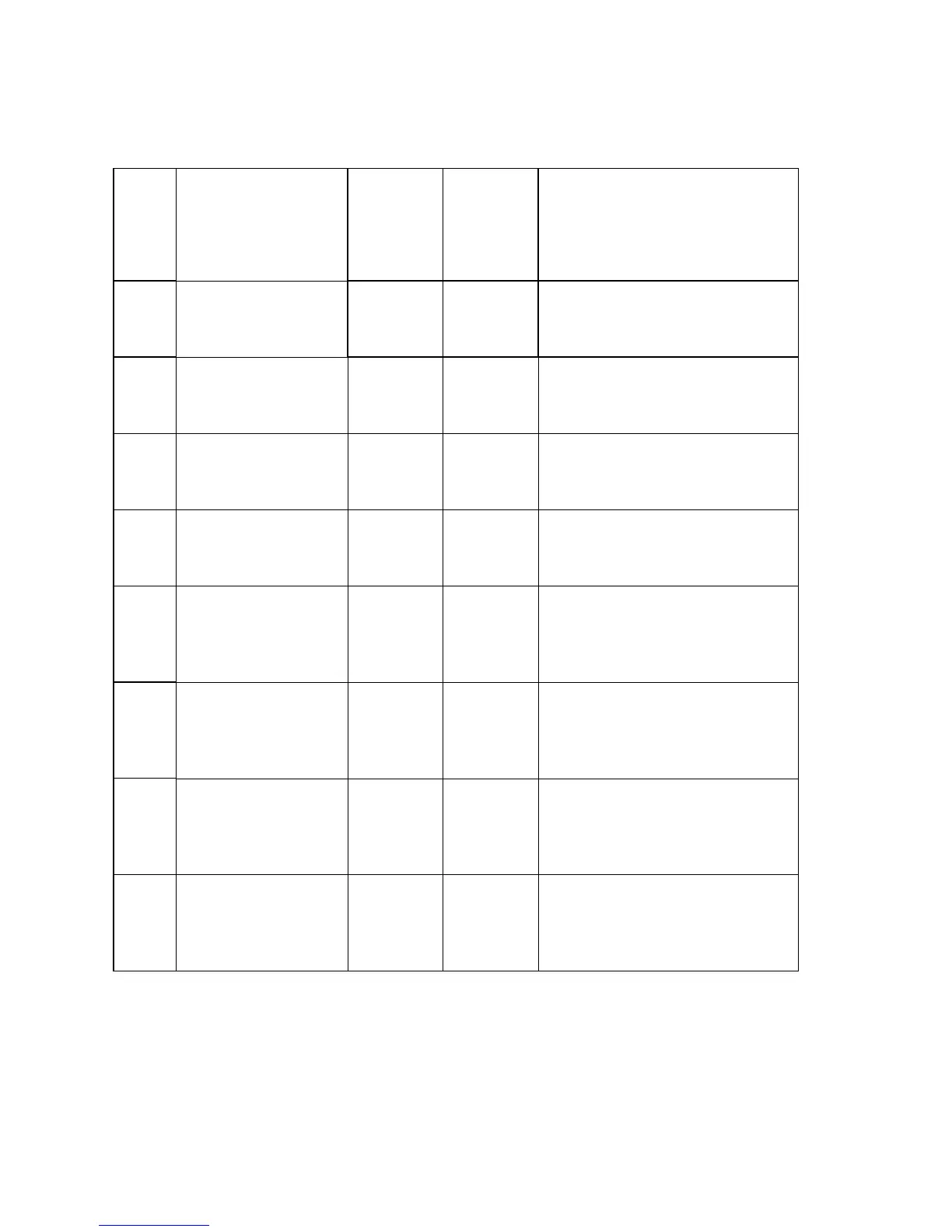

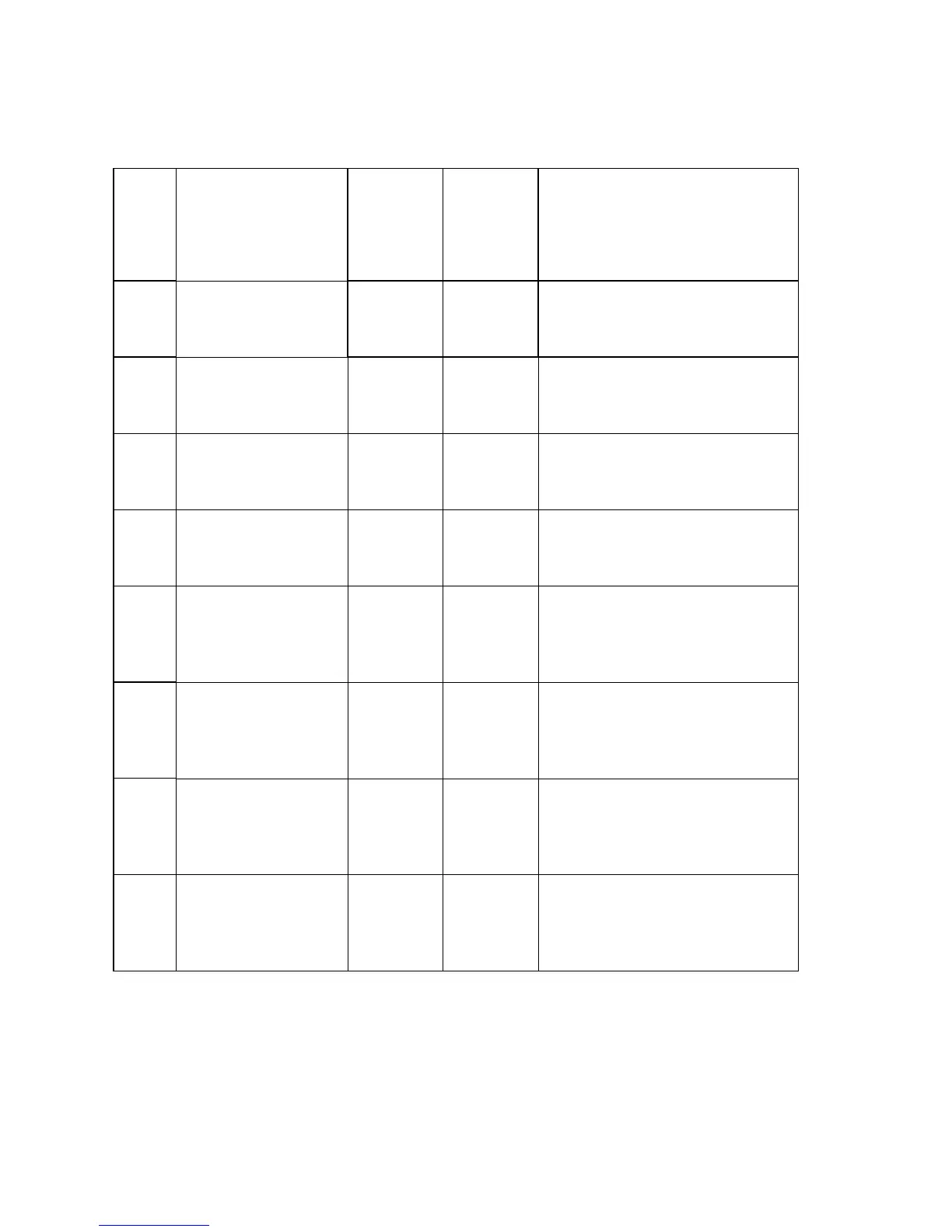

Y-axis Drive

This procedure performs a “4 corner” test using the minimum and maximum velocity and

acceleration used during printing and minimum and maximum load for a total of eight test cycles.

Measures servo response parameters under various conditions.

R# Definition

Typical

Value

(8400)

Typical

Value

(8500/

8550) Actions

0 HAHVN CCW

Average Fe (mpts)

4000 to

5700

4000 to

5800

Reports average following error

during the last half of the first

period.

1 HAHVN CCW Fe

Ripple (mpts)

100 to

380

0 to 500 Reports following error ripple

during the last half of the first

period.

2 HAHVN CW

Average Fe (mpts)

-5200 to

3800

-5500 to

-4000

Reports average following error

during the last half of the second

period.

3 HAHVN CW Fe

Ripple (mpts)

80 to 380 75 to 350 Reports following error ripple

during the last half of the second

period.

4 HAHVN Start Fe

Settle time (sec)

0.08 to

1.0

.05 to 0.2 Reports the time following the

start of motion that it takes the

following error value to enter the

CCW ripple band.

5 HAHVN Reverse Fe

Settle time (sec)

0.17 to

1.1

.12 to .3 Reports the time following the

start of motion reversing that it

takes the following error value to

enter the CW ripple band.

6 HAHVN Stop Fe

Settle time (sec)

-.001 to

0.15

-.001 to

.30

Reports the time following the

start of motion stopping that it

takes the following error value to

enter the idle ripple band.

7 HAHVN Delta Print

Velocity Settle Time

(sec)

0.02 to

0.10

0 to .11 Reports the time following the

start of motion that it takes the Y-

axis delta velocity to enter the

CCW delta velocity ripple band.

Loading...

Loading...