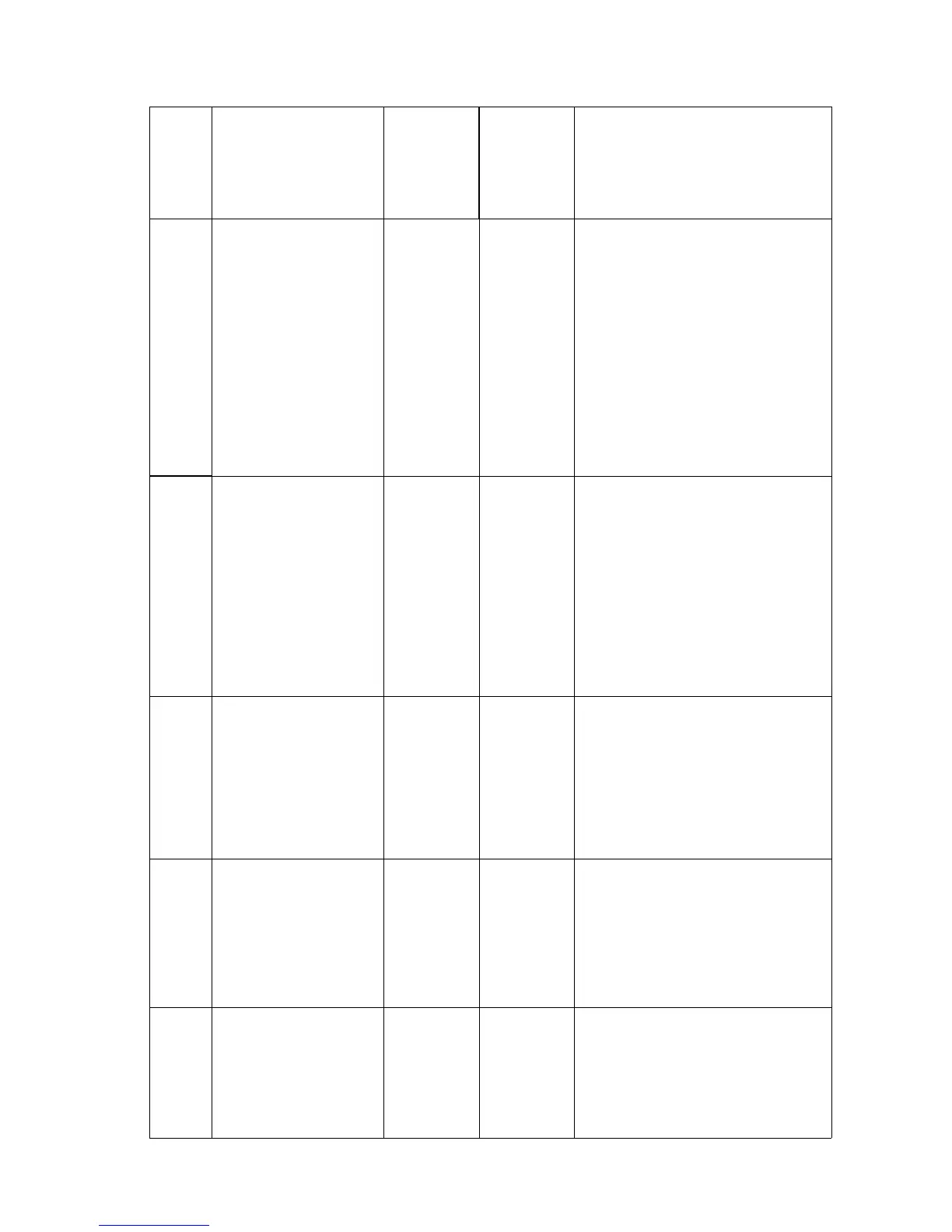

General Troubleshooting 4-23

2 Initial average MP fe.

(mpts).

-1 to

1400

Reports the average MP fe

immediately following the pick

shaft engagement.

A higher value of R2 could

indicate extra friction between

the cams and the lift plate

followers (wear, contamination,

etc.), as well as high lift plate

spring tension or higher shaft

bearing drag. Also, if the missing

tooth gear did not kick forward

and engage, this value would be

unchanged from R0.

3 Transition MP fe min.

(mpts).

750 to

1800

Reports the minimum MP fe

value at the transition point

between breaking separator pad

contact and the continued

depression of the lift plate.

Value reflects the effort needed

to rotate the pick shaft and

compress the lift spring. A higher

value of R3 could show higher

cam/bearing friction and/or lift

plate spring strength.

4 Contact average fe. 120 to

2000

Reports the average MP fe while

the pick roller is contacting the

separator pad. This value should

reflect the coefficient of friction

between the separator pad and

the pick roller. This value may be

effected by contamination or

glazing.

5 Pushdown MP fe

max.

750 to

2000

Reports the peak MP fe during

the interval when the pick cams

are depressing the lift plate.

A higher value here could

indicate issues with the cam

surfaces or the spring

compression force.

6 Final average MP fe.

(mpts).

900 to

1500

Reports the average MP fe

following the re latching of the

missing tooth gear.

This value should be the same

as R0 if the missing tooth gear

successfully relatched.

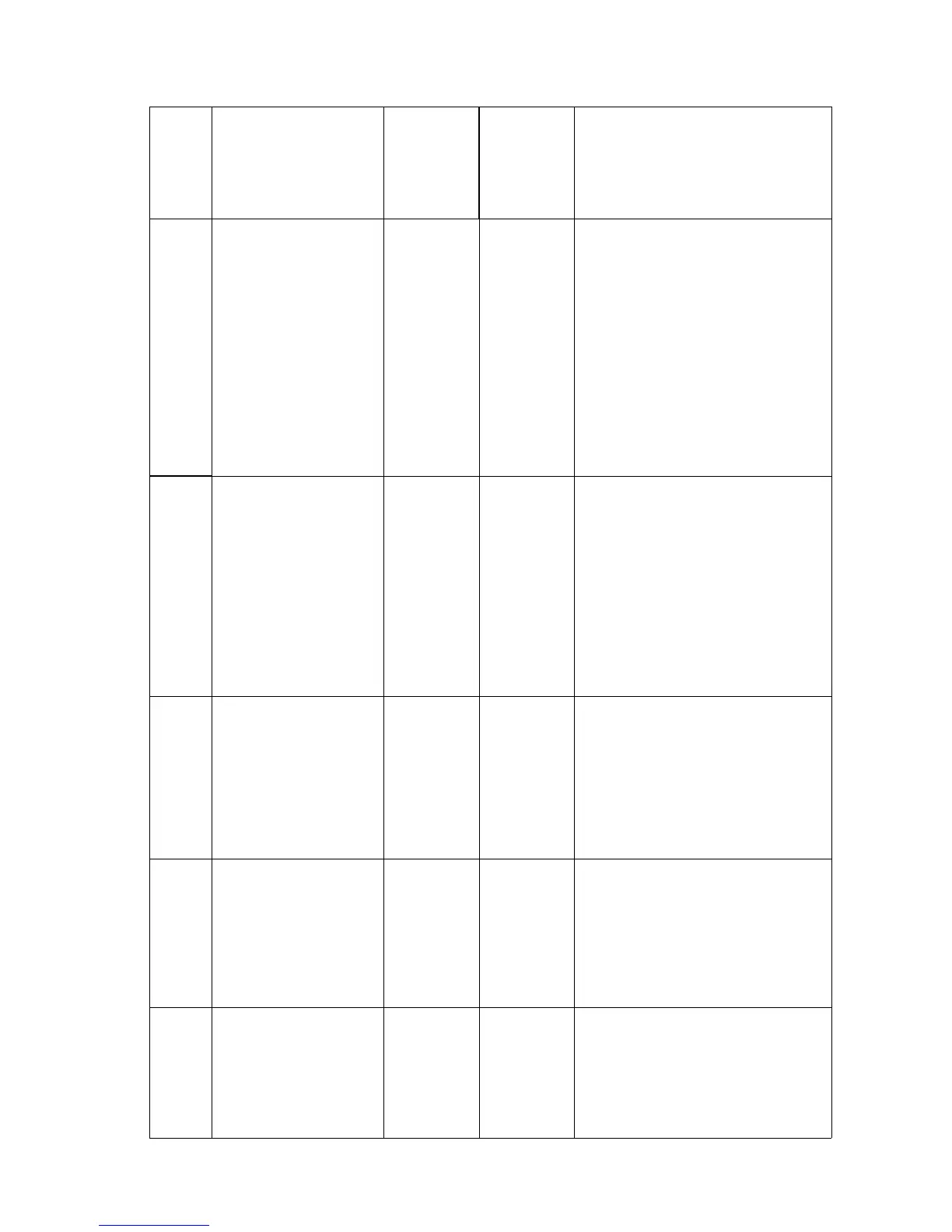

Tray 1 Pick Shaft (Continued)

Runs the media path drive train and engages the tray 1 pick solenoid on the fly. The pick shaft

goes through two full revolutions while drive requirements are determined.

R# Definition

Typical

Value

(8400)

Typical

Value

(8500/

8550) Actions

Loading...

Loading...