General Troubleshooting 4-39

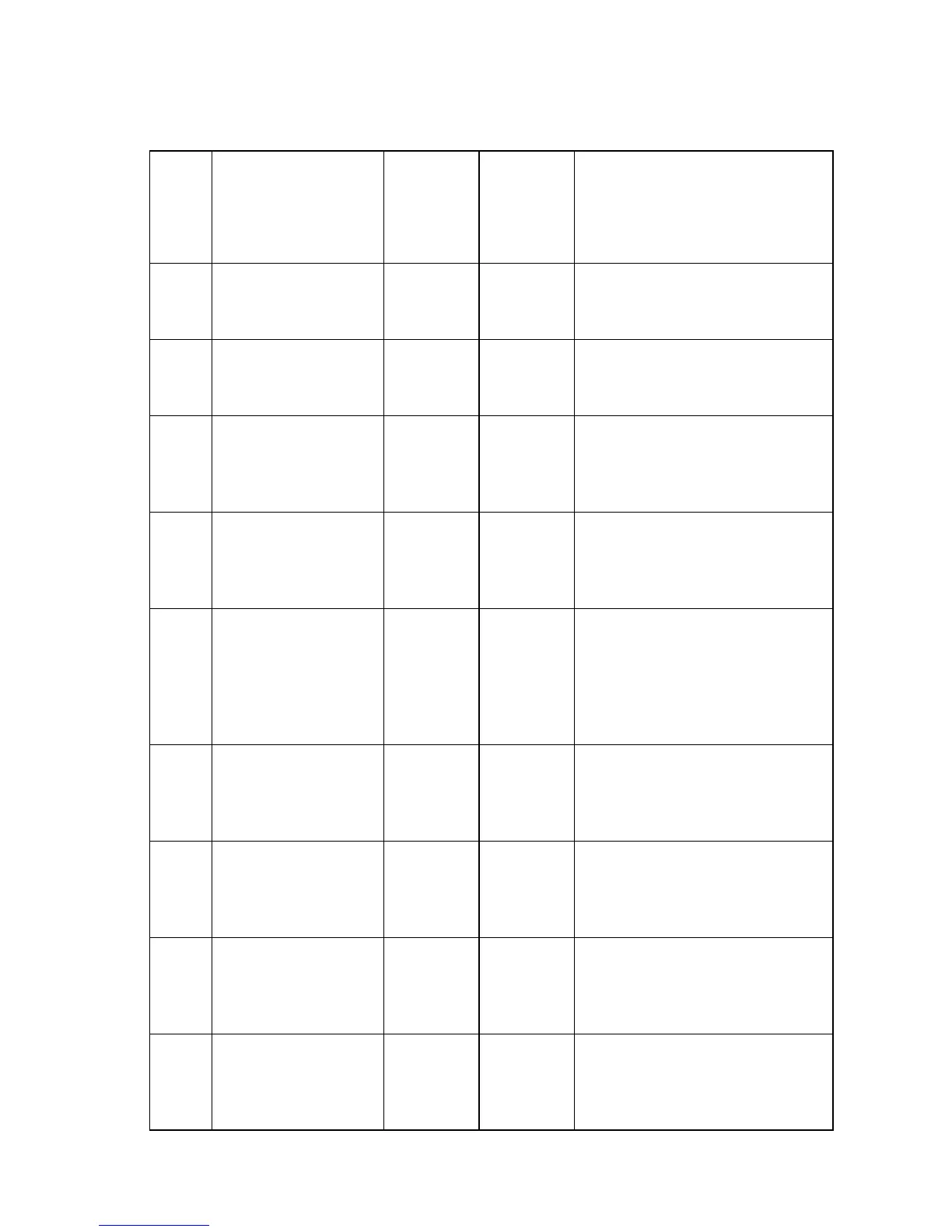

Drum Maintenance Drive

With the Y-axis rotating, the drum maintenance unit is loaded against the drum for a short time in

each configuration (roller and blade/blade only)

R# Definition

Typical

Value

(8400)

Typical

Value

(8500/

8550) Actions

0 Time to blade first

contact (sec)

.01 to .35 .15 to .4 Reports the time from the load

command to the engine until the

drum indicates blade contact.

1 Time to roller first

contact (sec)

.03 to 045 .2 to .50 Reports the time from the load

command to the engine until the

drum indicates roller contact.

2 Roller/Blade loaded

average Y-axis

following error

(mpts)

-700 to

-250

-650 to

-150

Reports the average Y-axis

following error during the Roll

With Both Loaded interval.

3 Roller/Blade loaded

Y-axis following error

ripple (mpts)

-50 to

300

0 to 600 Reports the difference between

the max and the min Y-axis

following error during the Roll

With Both Loaded interval.

4 Roller Average

Period (sec)

50 to

1600

-.05 to

.05

Reports the average period of

the Y-axis following error ripple

during the Roll With Both Loaded

interval. This variation would be

due to the dmu roller rolling

along the drum surface.

5 Roller Revs 3 to 40 Reports the number of Y-axis

following error ripple peaks

during the Roll With Both Loaded

interval.

6 Roller Disengaged

Time (sec)

-0.001 to

0.05

-.05 to

0.5

Reports the time from the unload

roller command to the engine

until the drum indicates no

further roller contact.

7 Blade loaded

average Y-axis

following error

(mpts)

-160 to

-50

-800 to

-100

Reports the average Y-axis

following error during the Roll

With Blade Loaded interval.

8 Blade loaded Y-axis

following error ripple

(mpts)

-0.001 to

0.50

115 to

900

Reports the difference between

the max and the min Y-axis

following error during the Roll

With Blade Loaded interval.

Loading...

Loading...