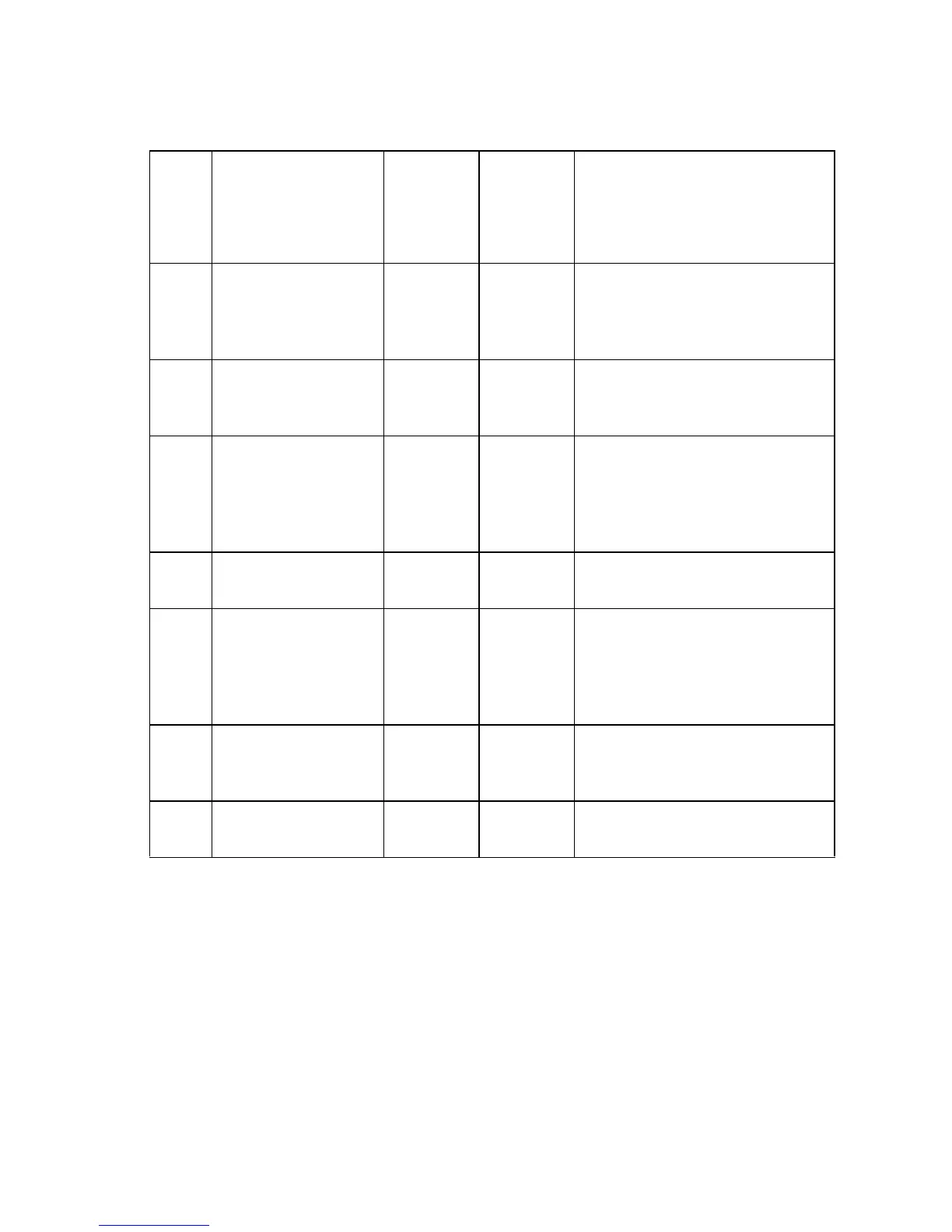

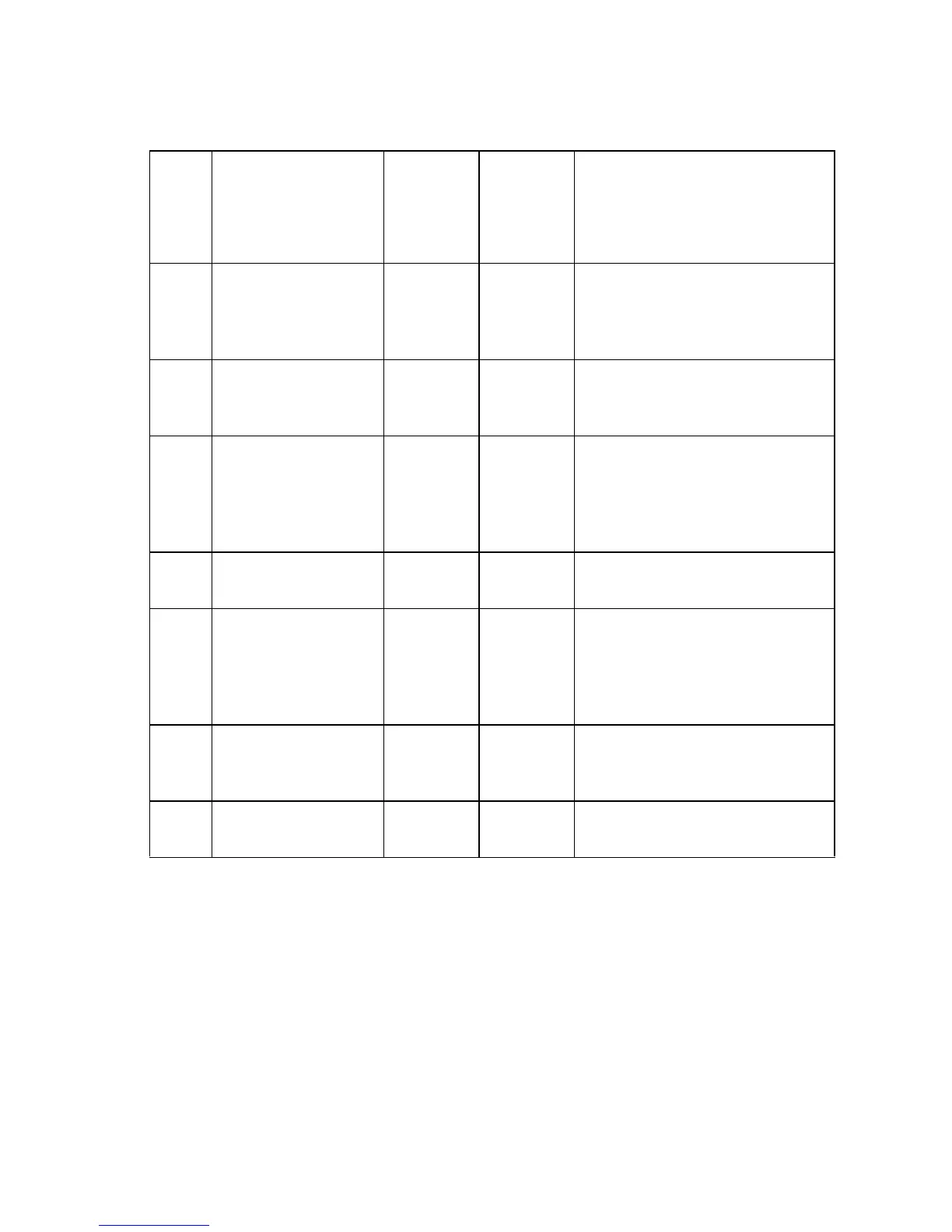

General Troubleshooting 4-41

Tray 2, Tray 3, Tray 4, Lift Plate Drive

This test raises the lift plate to verify motion and sensor operation. If the test is requested for a

525-sheet feeder that is not installed, an “Option Not Detected” message is generated.

R# Definition

Typical

Value

(8400)

Typical

Value

(8500/

8550) Actions

0 Tray Configuration Reports the tray status (present,

plate not lifted, etc.). See Paper

Path Status test for a description

of the configuration encoding.

1 Start Peak Power

(watts)

Reports the highest peak during

the first quarter of the lifting

interval.

2 Slack Take-up Time

(sec)

Reports the interval between the

initial power min (when the plate

is not yet engaged), and the point

where the lifting power becomes

a constant.

3 Average Lift Power

(watts)

Reports the average power over

the center ¾ of the lifting interval.

4 Lift Contact Time

(sec)

Reports the interval from the

motor start time until the required

lift power starts to increase due

to the initial contact with the

nudger roller assembly.

5 Lift Time (sec) Reports the interval from the

motor start time until plate lifted

is indicated.

6 Stall Power (watts) Reports the average stall power

during the overlifting interval

Loading...

Loading...