133

6 SERVICE, DISMANTLING, ASSEMBLY 6.7 OIL CHANGE

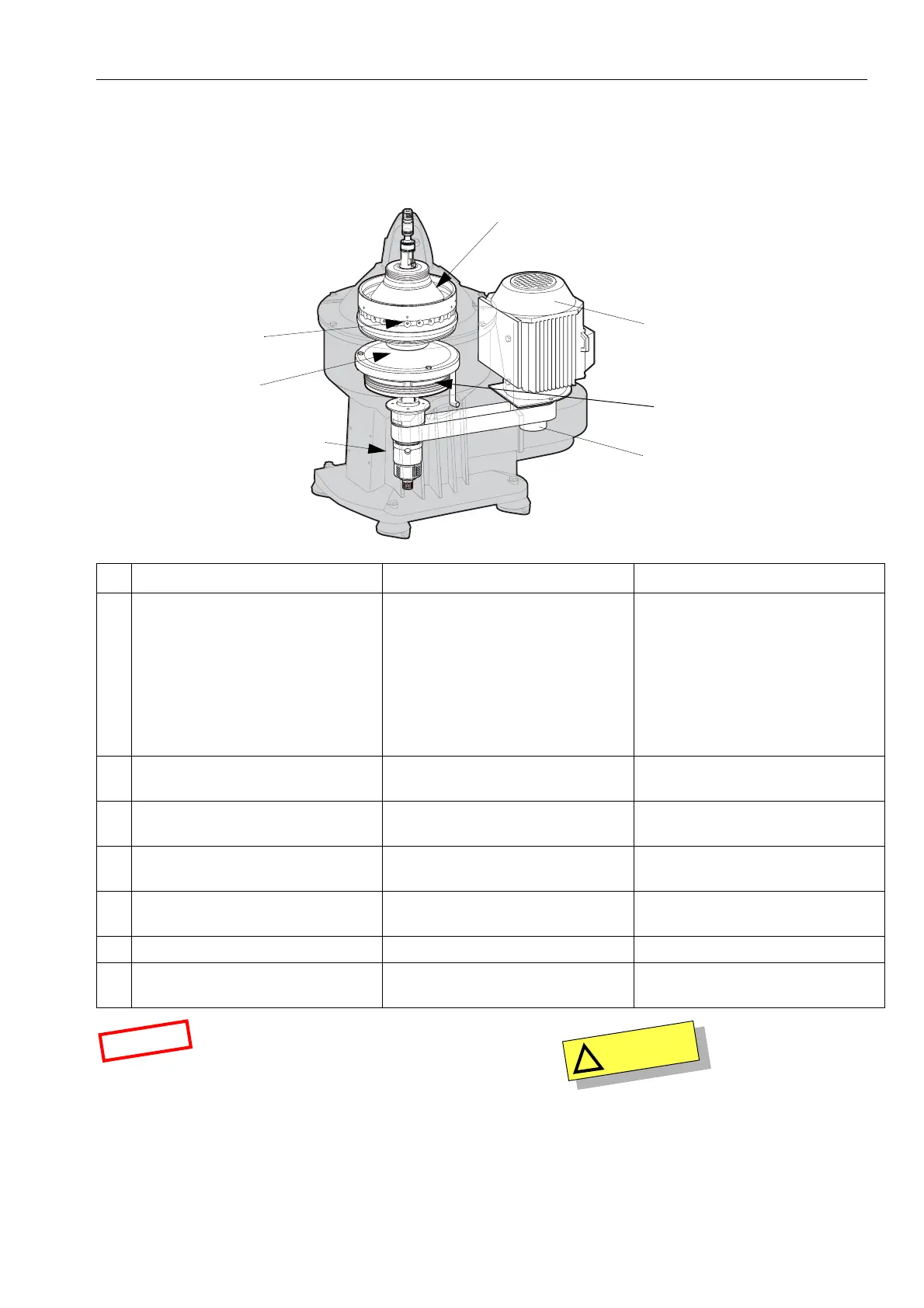

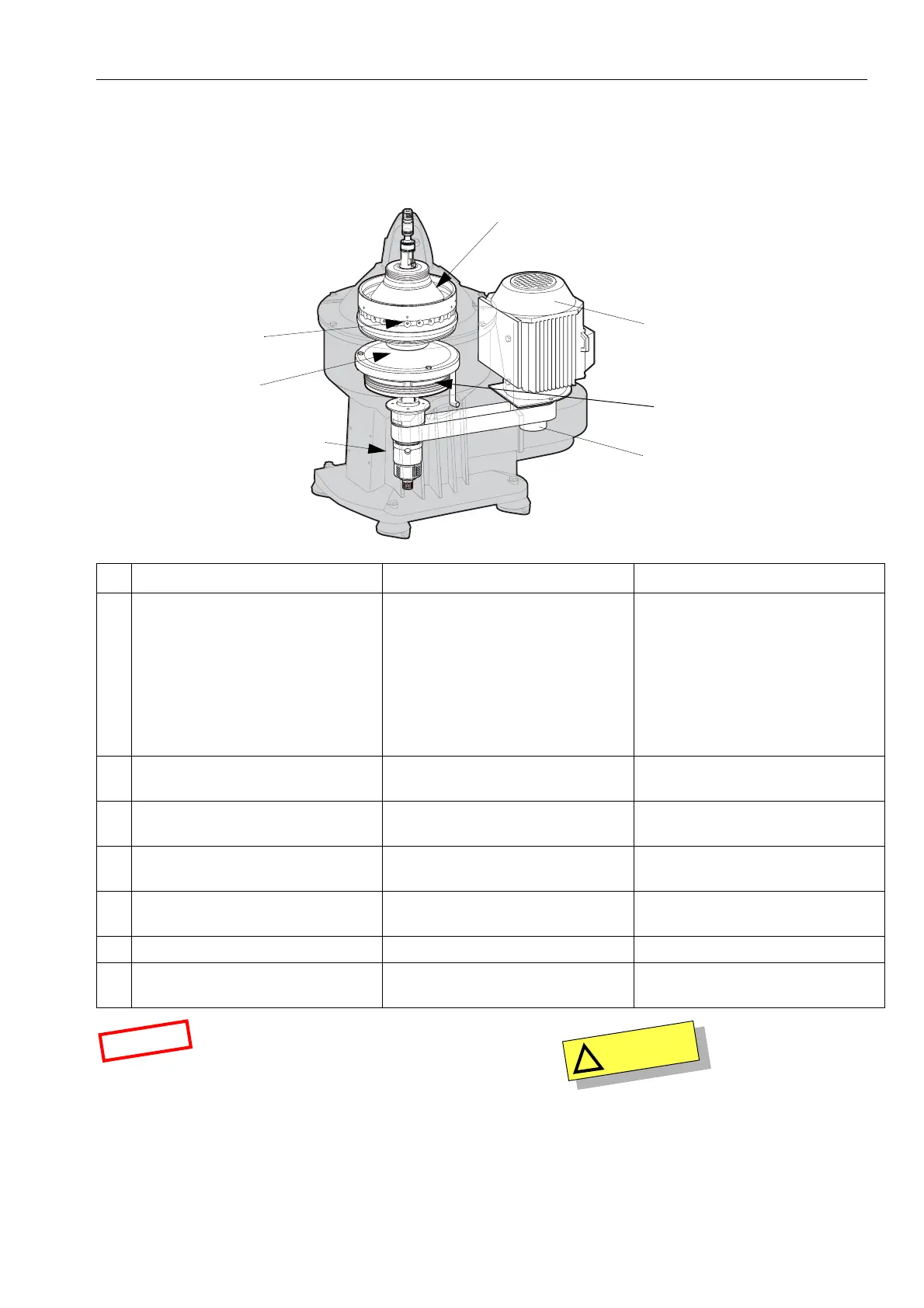

6.7.4 Lubrication chart

Alfa Laval ref. 567329-01, rev. 2

Lubricating points Type of lubricant Interval

1 The oil bath. Bowl spindle bearings

are lubricated by oil mist from the oil

bath.

See 6.7.1 Lubricating oil, page 131

Volume: 8.2 Technical Data, page 148

Ambient temperature 0 to +55°C

Oil change:

1. Continous operation: 4000 hours

2. Seasonal operation:

before every operating period

3. Short periods operation:

12 months even if total numbers of

operating hours is less than stated

above

2 Bowl spindle taper. Lubricating oil, only a few drops for

rust protection.

At assembling

3 Bowl: Sliding contact surfaces, thread

of lock nut and cap nut.

Pastes specified in 6.7.5 Lubricants,

page 134

At assembling.

4 Rubber seal rings. Grease as specified in 6.7.5

Lubricants, page 134

At assembling

5 Friction clutch bearings. The bearings are pre-lubricated with

grease.

No need for extra lubrication.

6 Electric motor. Follow the manufacturer’s instructions. Follow the manufacturer’s instructions.

7 Plug thread

(neck bearing assembly)

Lubricating oil. At assembly.

N

O

T

E

Check and pre lubricate new spindle bearings and

those that have been out of service for one month or

longer.

If not otherwise specified, follow the suppliers

instructions about applying, handling and storing of

lubricants.

C

A

U

T

I

O

N

!

Check the oil level before start.

Top up when necessary.

Do not overfill.

G0875441

Friction clutch bearings (5)

Electric motor (6)

Bowl spindle taper (2)

Bowl spindle and bearings (1)

Buffers (3)

Bowl (3), Rubber seal rings (4)

Plug thread (7)

Loading...

Loading...