6 SERVICE, DISMANTLING, ASSEMBLY SEPARATOR MANUAL

84 578701-02

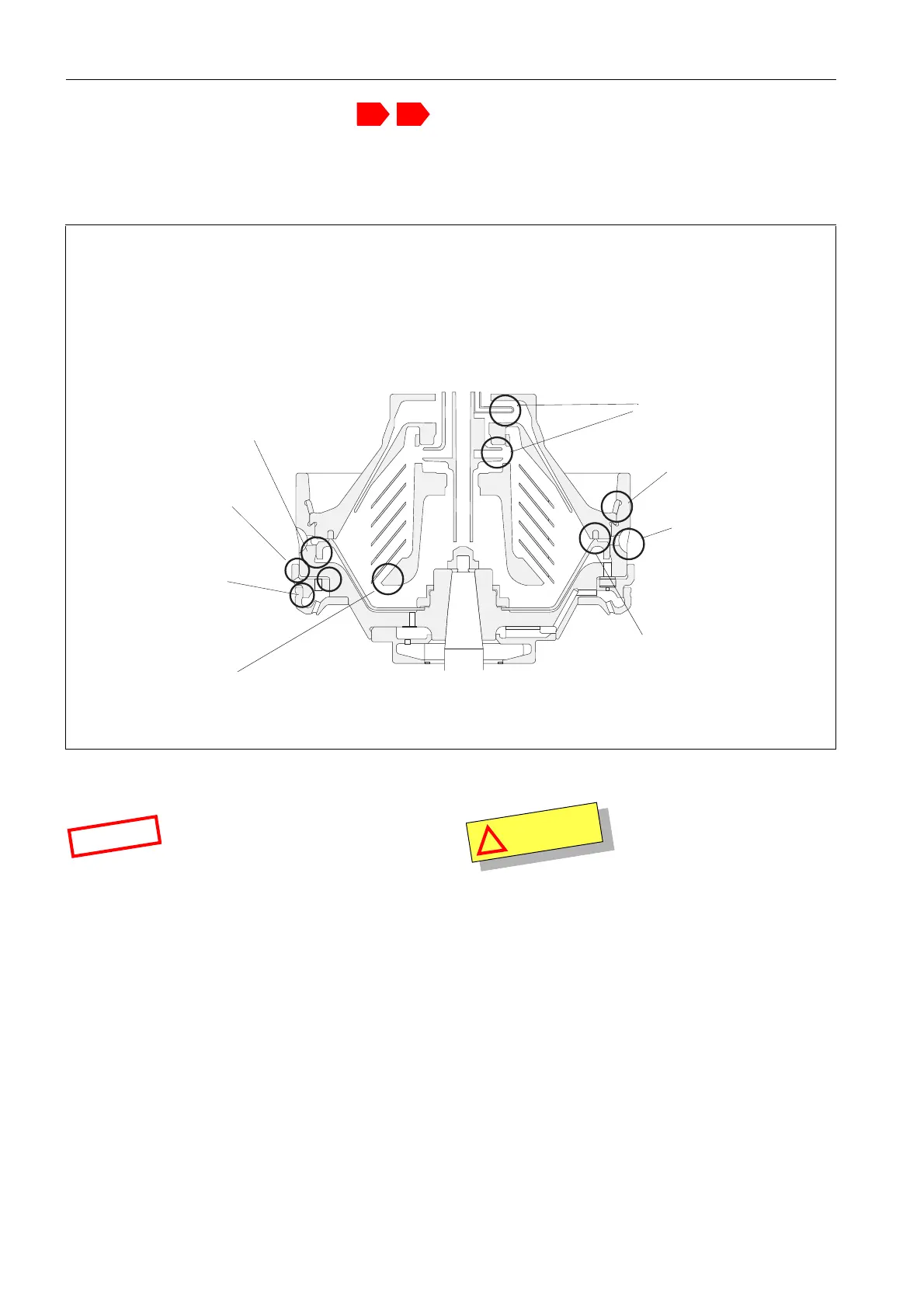

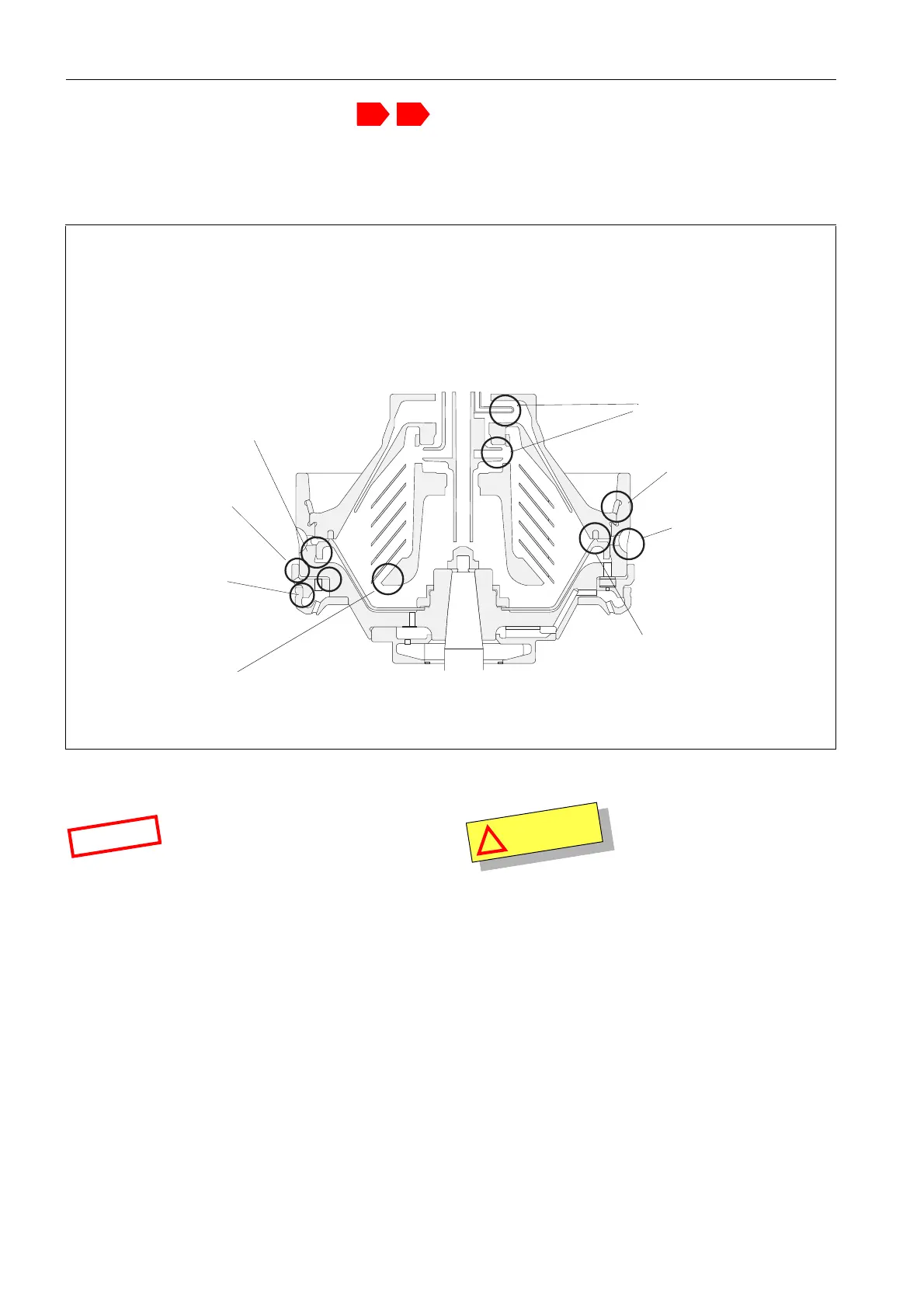

6.4.4 Inspection for erosion

Erosion may occur when particles

suspended in the process liquid slide along

or strike against a surface.

1 Inspect the bowl and inlet/outlet parts for

erosion damages.

2 Replace parts if erosion is suspected.

i o

G0911831

The underside of the distributor in the vicinity of the

distribution holes and wings

The sealing edge of the

discharge slide.

Pillars between the

sludge ports in the

bowl wall

Paring disc and paring tube

Lock ring

Surfaces particularly subjected to erosion are:

The sealing edge of the discharge

slide for the seal ring in the bowl

hood

Erosion is characterised by:

1 Burnished traces in the

material.

2 Dents and pits having a

granular and shiny surface.

Bowl body and holder.

Holder and operating slide.

N

O

T

E

Always contact your Alfa Laval representative if you

suspect that the depth of the damage exceeds 0,2

mm for bowl body and bowl hood (0,5 for other

parts). Do not continue to use the separator until it

has been inspected and cleared for operation by

Alfa Laval.

W

A

R

N

I

N

G

!

Disintegration hazard

Erosion damage weakens parts by reducing the

thickness of the material.

Pay special attention to the pillars between the

sludge ports in the bowl wall.

Replace parts if erosion is suspected of affecting

strength or function.

Loading...

Loading...