6.4 ACTIONS BEFORE ASSEMBLY 6 SERVICE, DISMANTLING, ASSEMBLY

82

6.4.2 Inspection for corrosion

Inspect the separator parts for corrosion.

Evidence of corrosion attacks should be looked

for and rectified each time the separator is

dismantled.

W

A

R

N

I

N

G

!

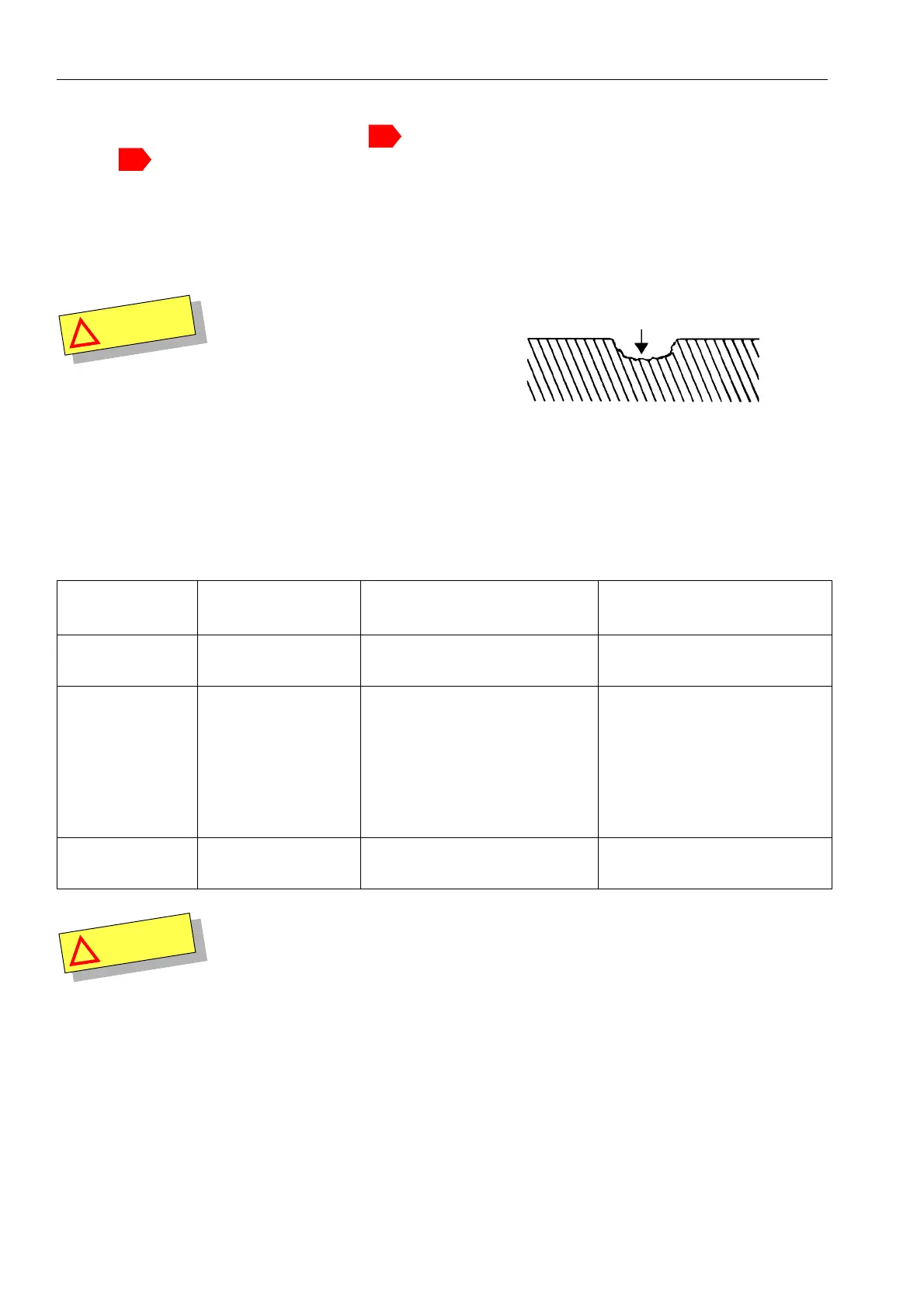

Disintegration hazards

Always contact your Alfa Laval representative if you

suspect that the depth of the corrosion damage

exceeds 0,2 mm for bowl body and bowl hood (0,5

for other parts) or if cracks have been found. Do not

continue to use the separator until it has been

inspected and given clearance for operation by Alfa

Laval.

Material Type of corrosive

environment

Appearance Measure

Non-stainless steel

and cast iron parts

Water or dampness Rust If damage exceeds 0,5 mm, contact

Alfa Laval.

Stainless steel Chlorides or acidic

solutions

Acidic solutions cause general

corrosion.

Chloride corrosion begins as small

dark spots that can be difficult to

detect, and goes on to local damage

such as pitting, grooves or cracks.

Polish dark-coloured spots and

other corrosion marks with a fine

grain emery cloth. This may prevent

further damage.

If damage exceeds 0,5 mm (0,2 mm

for bowl body and bowl hood)

contact Alfa Laval.

Other metal parts “Aggressive”

environment

Possible corrosion damage can be

in the form of pits and/or cracks.

If damage exceeds 0,5 mm, contact

Alfa Laval.

W

A

R

N

I

N

G

!

Disintegration hazard

Pits and spots forming a line may indicate cracks

beneath the surface.

All forms of cracks are a potential danger and are

totally unacceptable.

Replace any part where corrosion can be

suspected of affecting its strength or function.

i

o

G0205241

Max. 0,2 mm

Loading...

Loading...