6.4 ACTIONS BEFORE ASSEMBLY 6 SERVICE, DISMANTLING, ASSEMBLY

88

6.4.8 Check for galling on operating

slide and bowl body

G0874851

a Clean the surface thoroughly with a degreasing

agent, i.e. white spirit.

This is important!

1

1

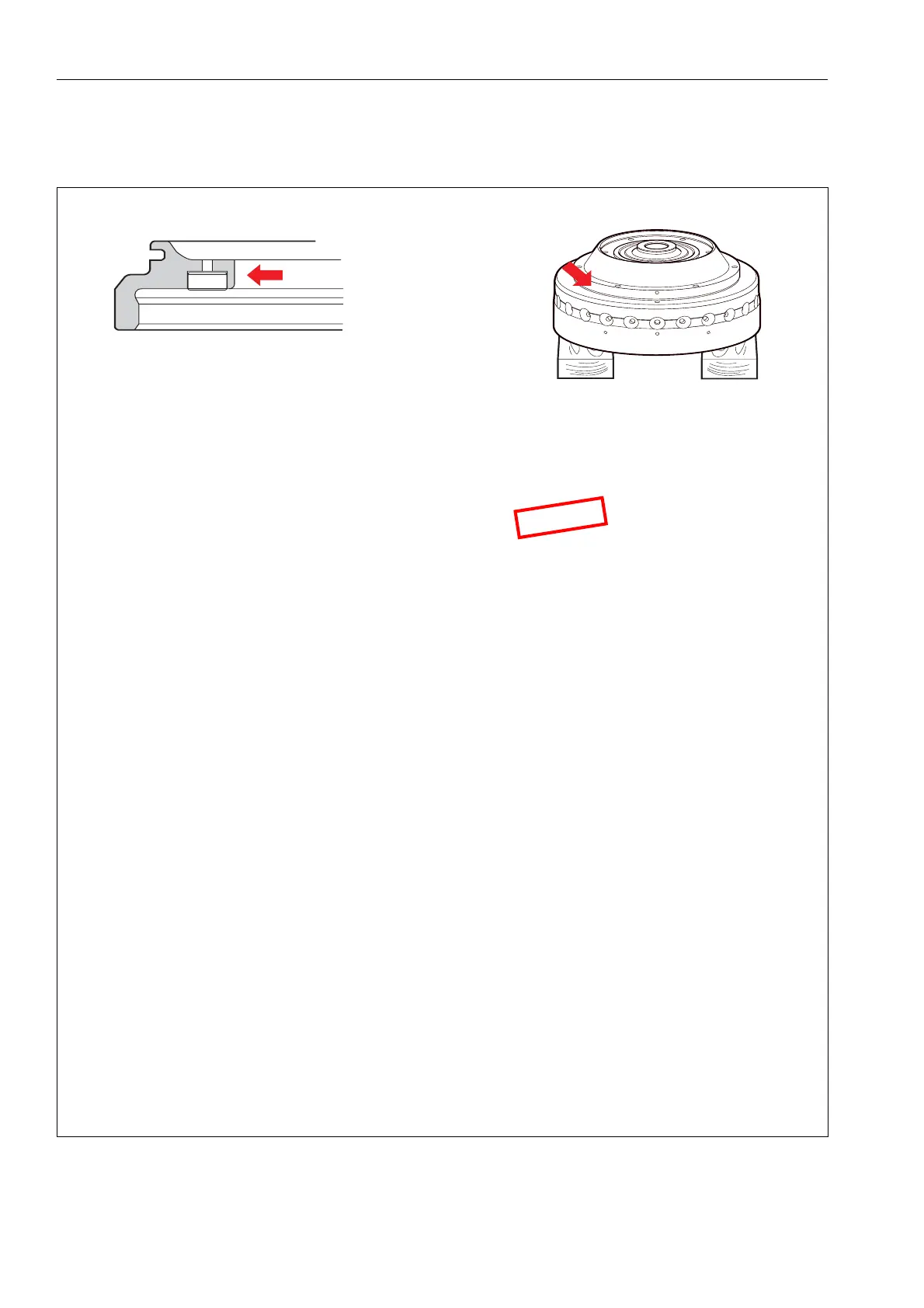

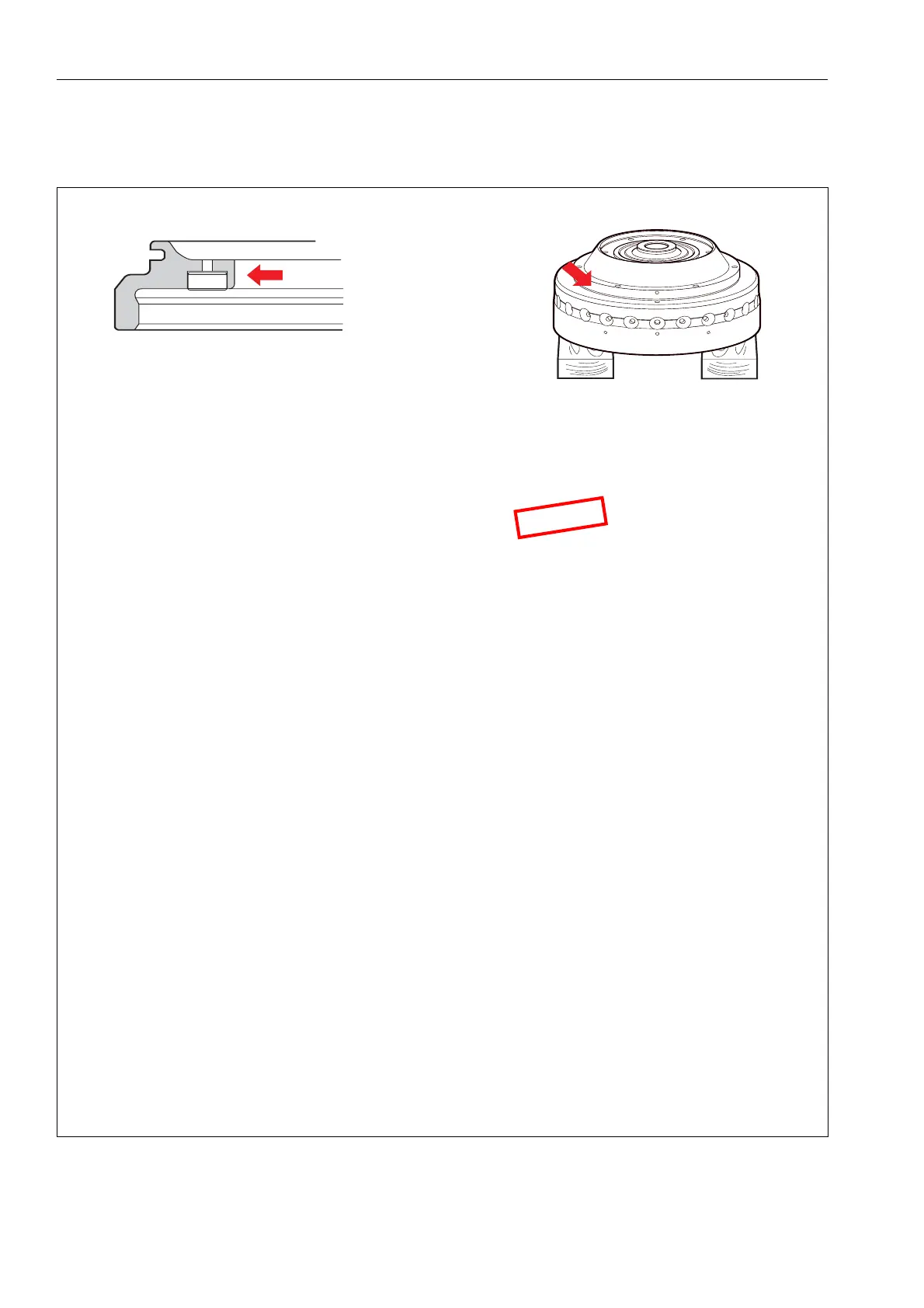

If any friction marks are found on the guide surfaces (1)

of operating slide and bowl body, proceed as follows:

b Using an emery cloth (e.g. No. 320) to smooth the

metal edges.

c Finish by polishing the damaged spots with polishing

paper (e.g No. 600).

d Apply Molykote D321R on surfaces.

e Air-cure for 15 minutes.

f Polish to an even, homogenous surface.

g Apply a second layer.

h Air-cure for 15 minutes.

i Polish to a shiny surface, the surface should look like

well-polished leather when properly done.

j Finish the treatment by lubricating the guiding surfaces

with Alfa Laval lubricating paste or Molykote 1000

paste. Use a well cleaned brush. Rub it into the

surface, do not leave any excessive paste.

N

O

T

E

To avoid the risk of galling, the

guiding surface of the operating

slide should be primed with a slide

lacquer at every inspection

service.

Loading...

Loading...