7.2 SEPARATING FUNCTIONS 7 FAULT FINDING

144

7.2 Separating Functions

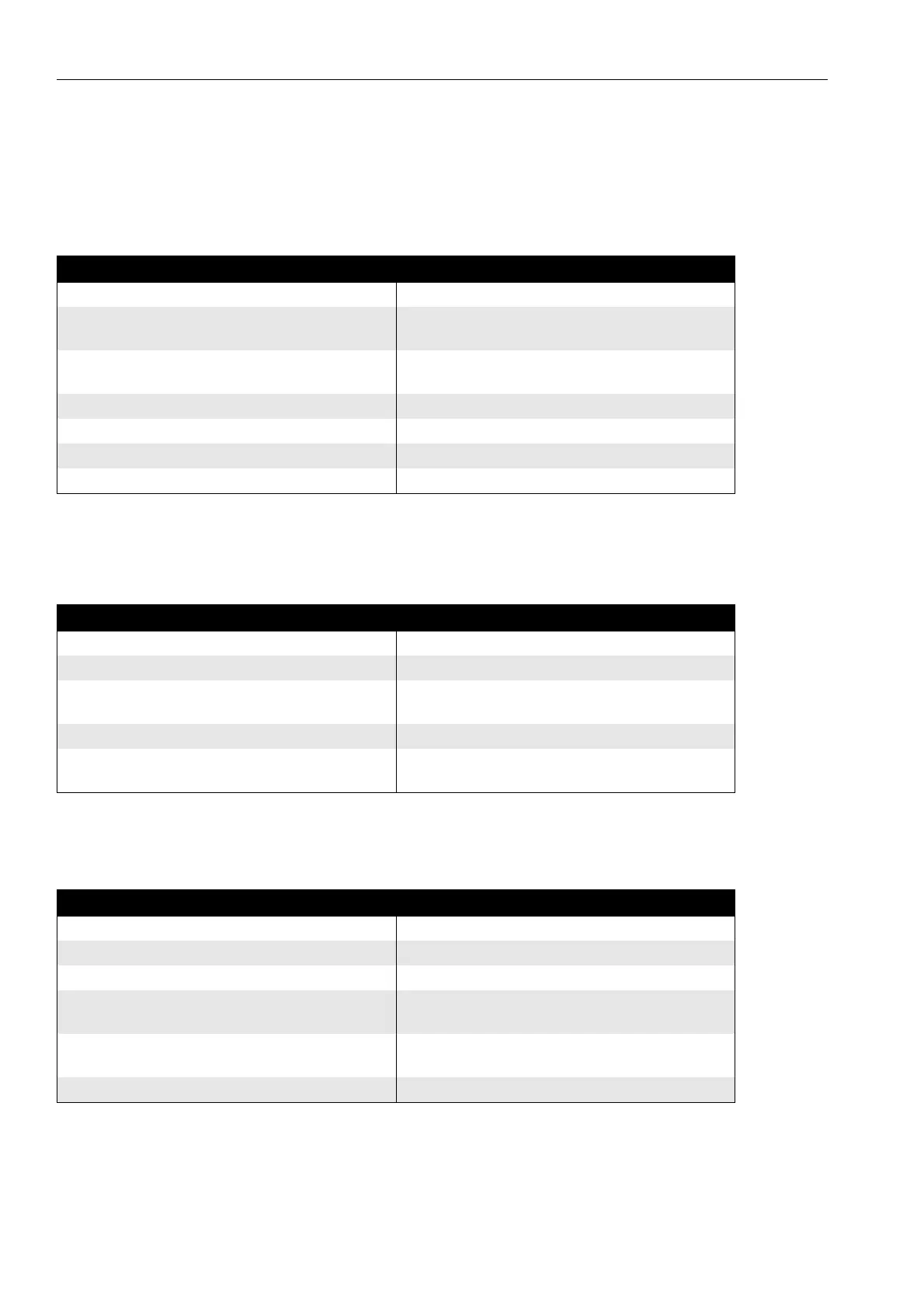

7.2.1 Bowl opens accidentally

during operation

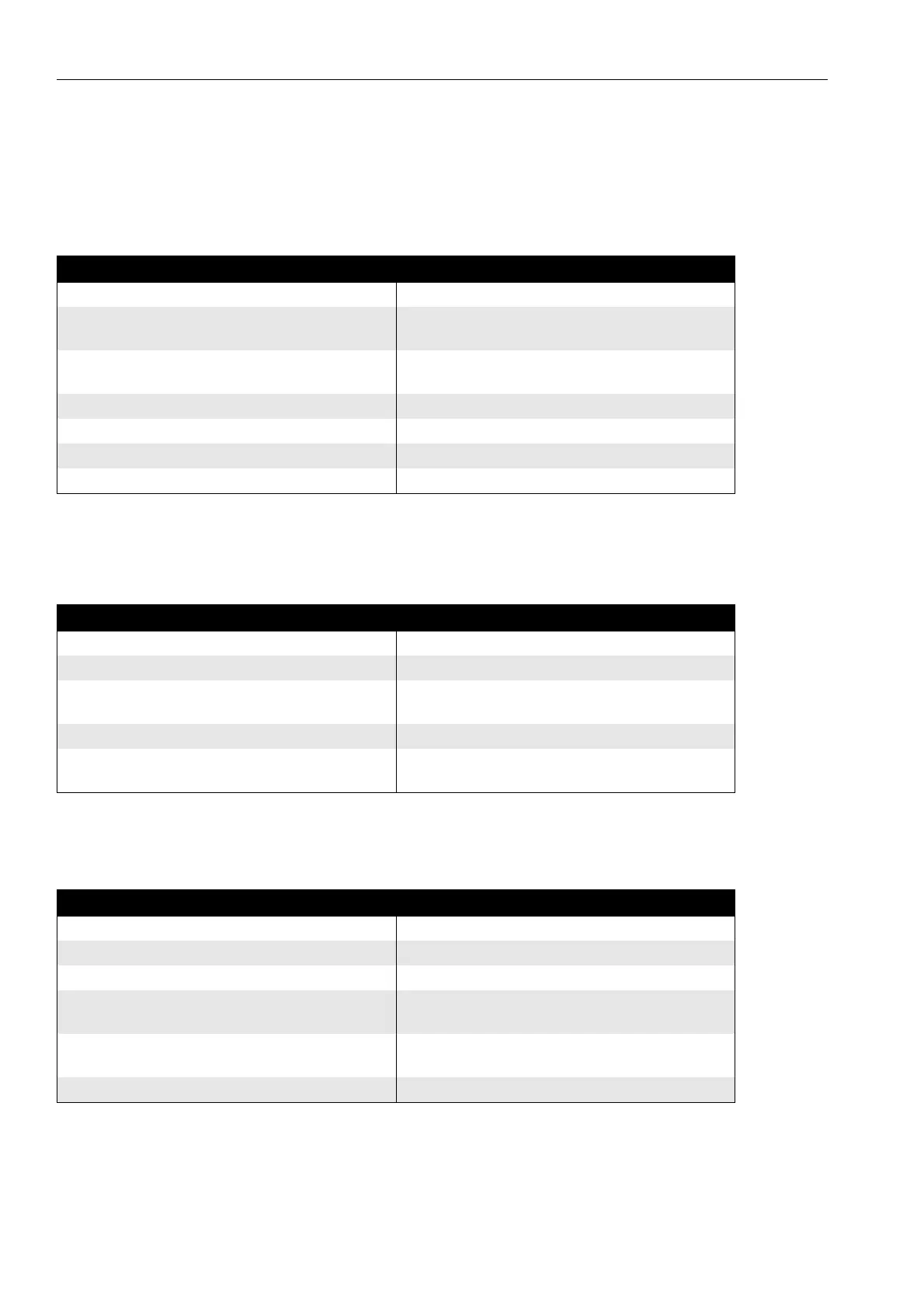

7.2.2 Bowl fails to open for sludge

discharge

7.2.3 Unsatisfactory separation

result

Cause Corrective action

Strainer in the operating water supply is clogged. Clean the strainer.

No water in the operating water system. Check the operating water system and make sure

the valve(s) are open.

Hoses between the supply valves and separator are

incorrectly fitted.

Correct.

Nozzle in operating slide clogged. Clean the nozzle.

Rectangular ring in discharge slide is defective. Renew the rectangular ring.

Valve plugs are defective. Renew all plugs.

Supply valve for opening water is leaking. Rectify the leak.

Cause Corrective action

Strainer in the operating water supply is clogged. Clean the strainer.

Water flow too low. Check the water flow

Hoses between the supply valves and separator are

incorrectly fitted.

Correct.

Nozzle in operating slide missing. Fit the nozzle.

Rectangular ring in the operating slide or bowl body

is defective.

Renew the rectangular rings.

Cause Corrective action

Incorrect separation temperature. Adjust.

Throughput too high. Adjust.

Disc stack is clogged. Clean disc stack.

Sludge space in bowl is filled. Clean and reduce the time between sludge

discharges.

Bowl speed too low. Examine the motor and power transmission including

the belt transmission (clutch).

Bowl rotates i wrong direction Check the electrical connections to the motor.

Loading...

Loading...