3.

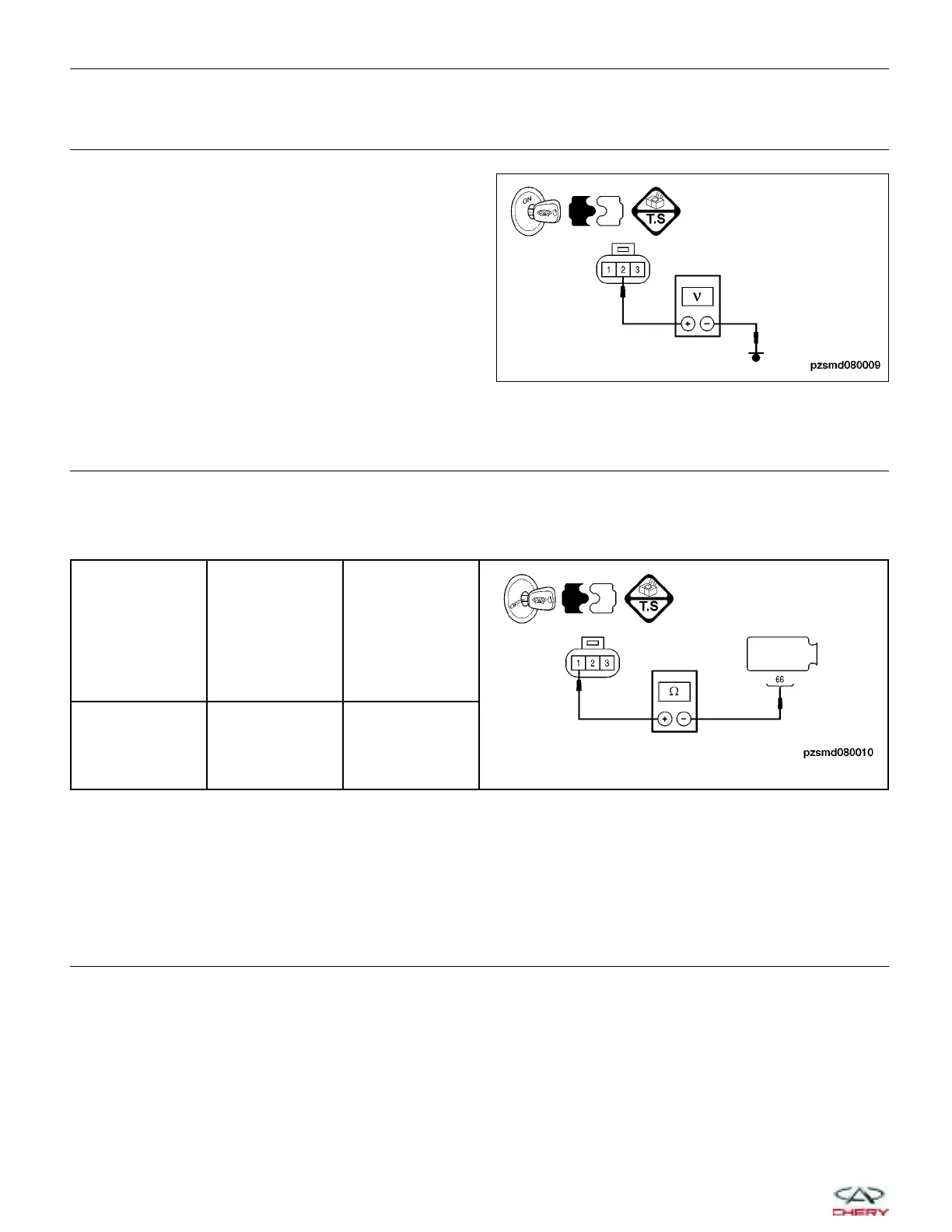

CHECK HYDRAULIC PRESSURE SENSOR POWER SUPPLY

• Turn ignition switch on.

• Check the voltage between hydraulic pressure sen-

sor terminal 2 and ground in the sensor electrical

connector P-009, terminal side.

• 5 V should exist.

Is the check result normal?

Yes

>> Go to the next step.

No

>>

Repair or replace the circuit for an open,

short to power or short to ground.

If circuit is normal, replace the AMT con-

trol module (See AMT control module

Removal & Installation in Section 08 Transaxle).

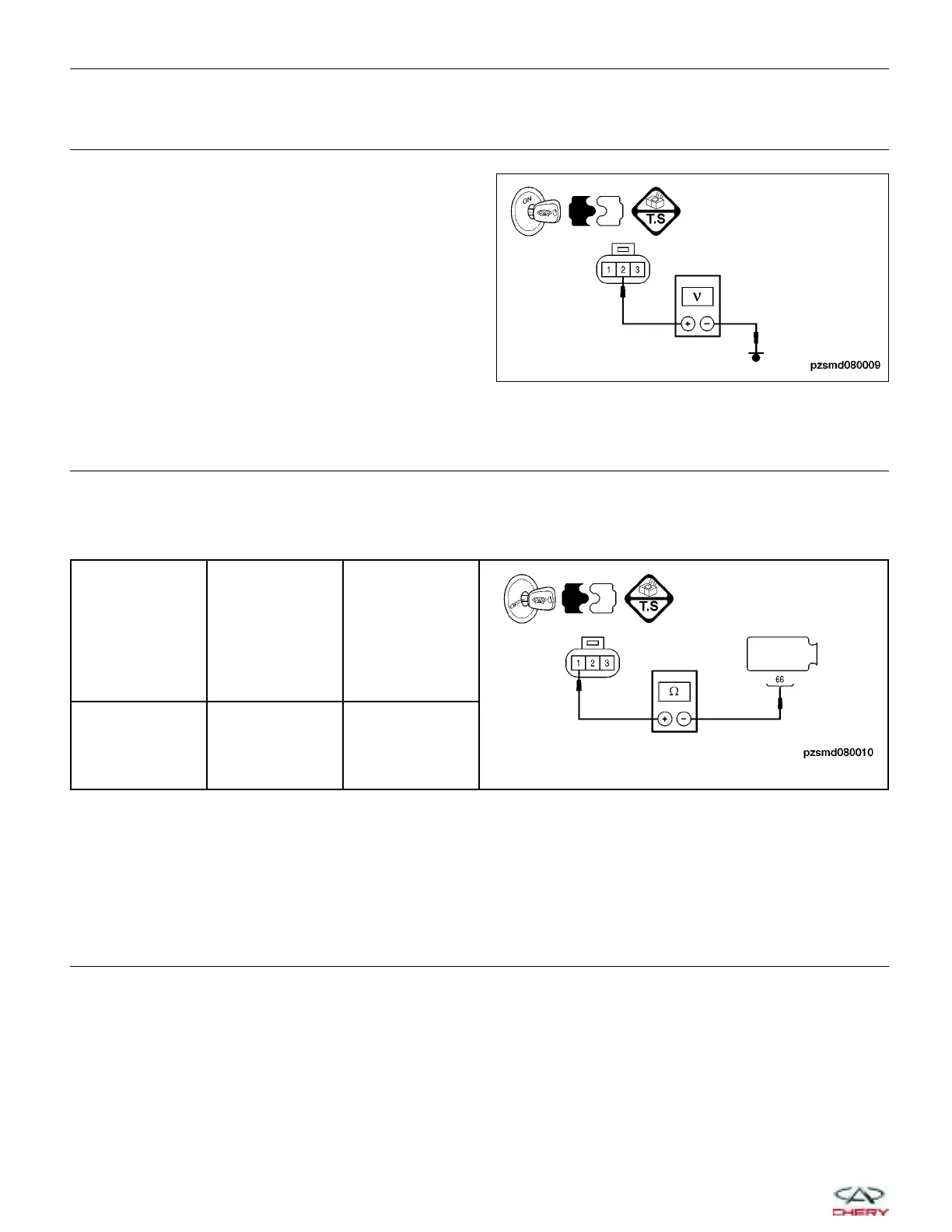

4.

CHECK HYDRAULIC PRESSURE SENSOR GROUND CIRCUIT

• Turn ignition switch off.

• Disconnect the AMT control module electrical connectors E-602 and E-603.

• Check the continuity between the following terminals:

SYSTEM

PRESSURE

SENSOR

TERMINAL

AMT CONTROL

MODULE

CONNECTOR

TERMINAL

CONTINUITY

1 66 Yes

• Check the harness for a short to power and a short to ground.

Is the check result normal?

Yes

>> Go to the next step.

No

>> Repair or replace the circuit for an open, short to power or short to ground.

5.

CHECK HYDRAULIC PRESSURE SENSOR SIGNAL CIRCUIT

• Check the continuity between terminal 3 of the hydraulic pressure sensor connector P-009, and terminal 40 of

the AMT control module electrical connector E-062, terminal side.

• Continuity should exist.

• Check the signal circuit for a short to ground and a short to power supply.

Is the check result normal?

Yes

>> Go to step 6.

No

>> Check the harness for an open, short to ground or short to power supply in the harness.

DIAGNOSIS & TESTING

PZSMD080009

08–94

Chery Automobile Co., Ltd.

Loading...

Loading...